Production speed: | 30-80 pieces/min |

Filling volume: | 5-300ml/piece |

Filling accuracy: | ≤±0.5% |

Applicable pipe diameter: | 13.5-60mm |

Applicable tube length: | up to 230mm |

Voltage: | 380V |

Working pressure: | 0.6Mpa |

Size: | 2.38×1.2×2.3(m) |

Net weight: | 1500kg |

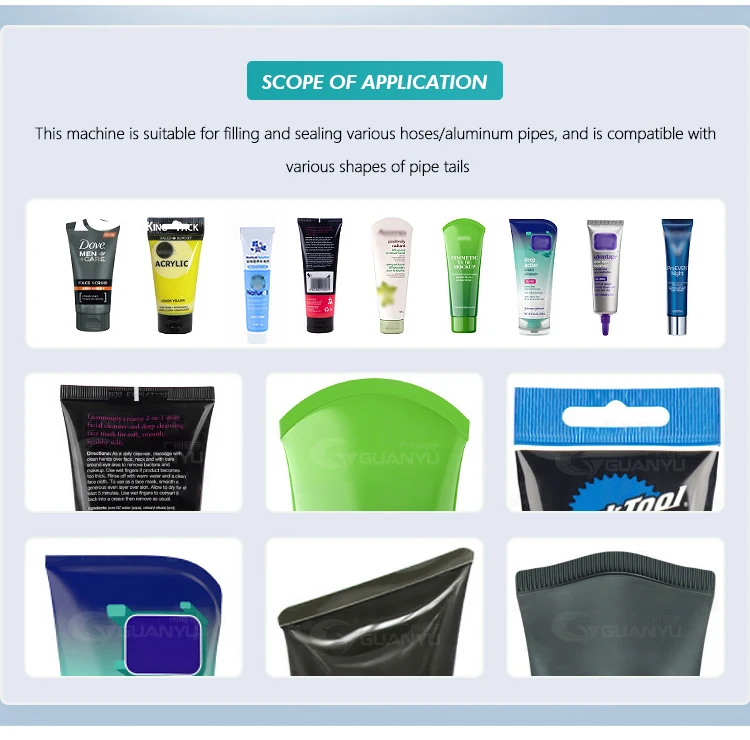

Optional: | hose/aluminum tube/metal tube |

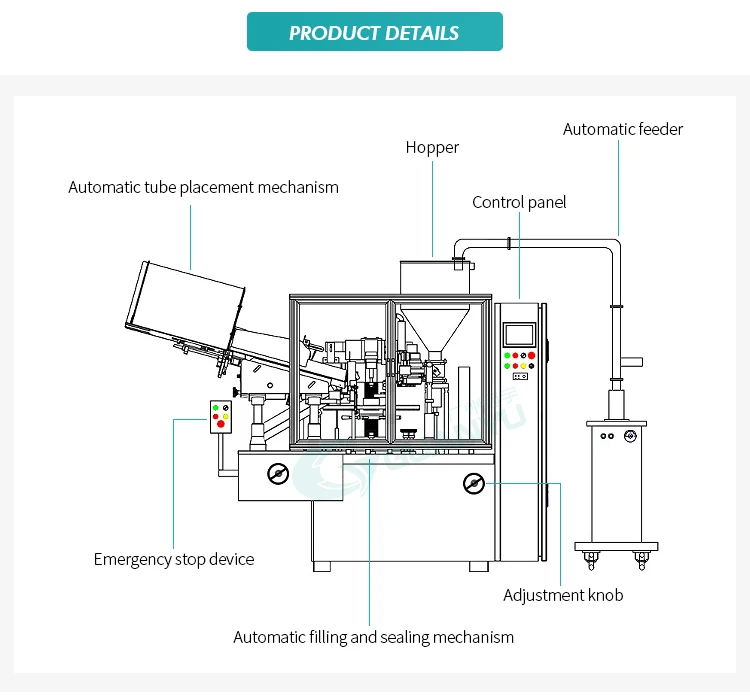

①Automatic tube loading mechanism:

Put the tubes into the slot and they will be automatically transported to the work tray by the tunnel.

②Work tray:

The mold used to place the pipe, the diameter can be customized 13.5-60mm, one machine can customize multiple sets of molds for more pipes of different diameters

③Automatic photoelectric identification and benchmarking:

This sensor is for automatic orienting the tube according to the color mark on tube Tail

④Precision filling:

Filling nozzles will be customized according to different pipe diameters to ensure filling without splash/overflow

①Tube end folding device:

Combining several processes of bending, clamping and folding, it is used to seal the end of the tube. The date can be printed to the tail while it is sealed

②Automatic unloading:

The finished tube will be automatically unloaded from here

Reviews

There are no reviews yet.