Max filling speed | filling 200ml, 2000~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming andother physical property |

Filling dose | 100~ 1000ml (Customizable) |

Filling accuracy | ±1% |

Voltage | AC220V/380V, 50/60HZ |

Working pressure | 0.4 ~ 0.6MPa |

Program control | PLC+touch screen man-machine interface |

Capping speed | 2000-3000 bottles/hour |

Lower cover way | Manual or vibrating plate |

Capping head | Customize different caps according to different caps |

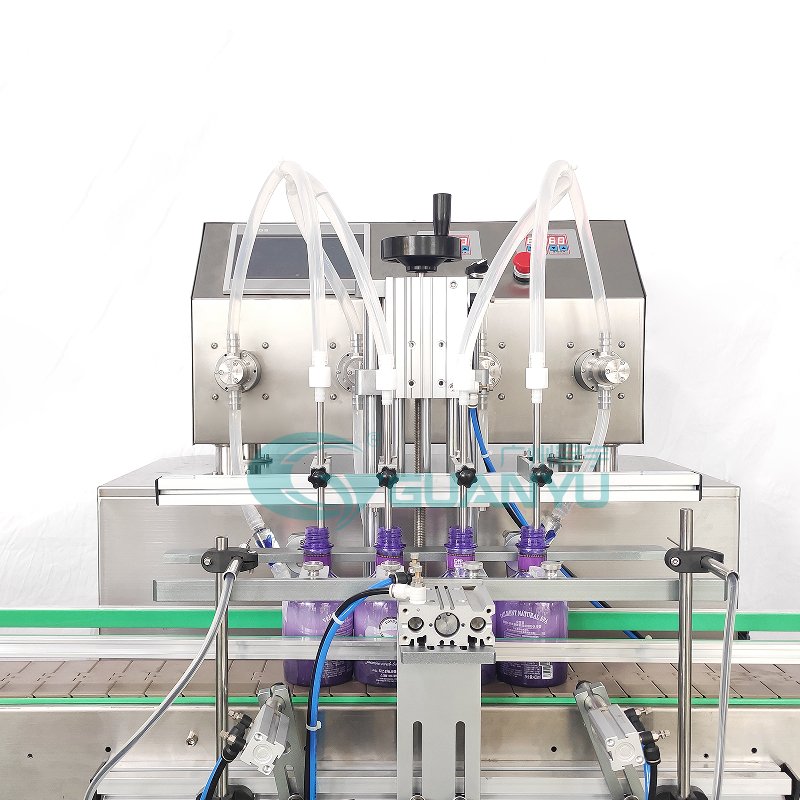

Main Features(Filling machine):

1、The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specificationswithout replacing parts, which can meet the production requirements of multiple varieties and specifications.

3、The use of internatioal famouse brand electrical components, performance and stability.4、Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.5、Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

Main Features(Capping machine):

1. The cap elevator and vibrating feeder can be selected according to the shape of the cap and the type of cap

4. The tank body of the equipment does not rotate when the cap is screwed, which avoids the displacement, scatteringand possible damage of the products contained in the tank.

Reviews

There are no reviews yet.