Our advantages:

◭ Our own factory: Our factory has 7000 square meters, more than 100 workers, and 6 machine production lines, including machine manufacturing, polishing, and testing.

◭ Customized Machinery: Our main products include fixed vacuum emulsifying machines, mobile homogenizers, all kinds of reaction agitator kettles.

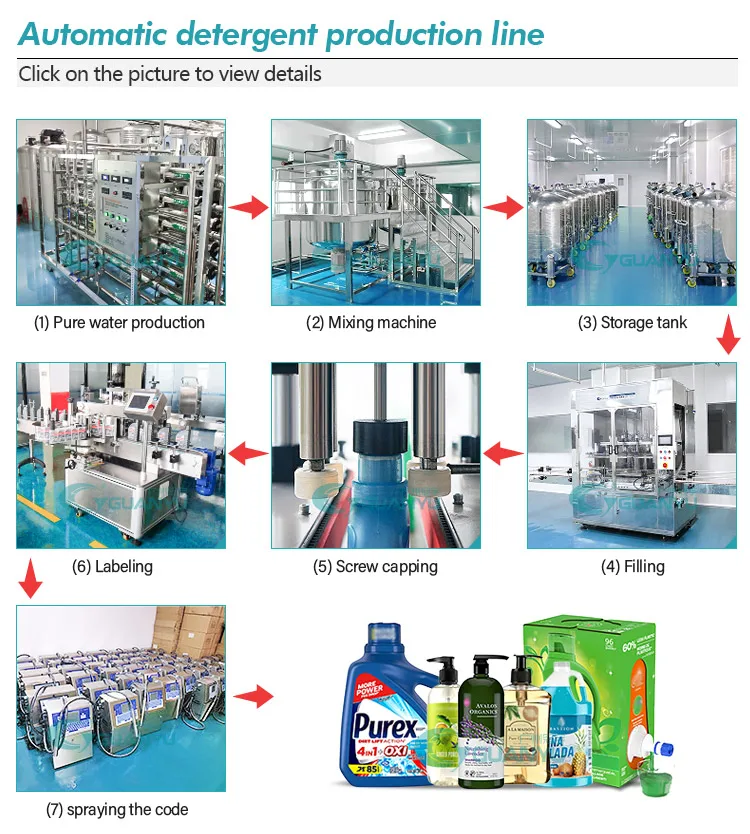

◭ Applicable Products: They are suitable for making cream, lotion, liquid products, including face cream, ointments, ketchup, mayonnaise, jam, hand soap, shampoo etc.

◭ Certifications: CE, GMP, UL and patented technology certificates.

Specification | Working Volume (L) | Heating Method(optional) | Dimension(L*W*H) (m) | Weight(kg) |

GYE-50 | 50 | Electric heating or steam heating | 2.6*2.4*2 | 650 |

GYE-100 | 100 | 2.8*2.5*2.2 | 850 | |

GYE-200 | 200 | 3*2.8*2.3 | 1100 | |

GYE-500 | 500 | 3.3*3*2.5 | 1500 | |

GYE-1000 | 1000 | 4.2*3.5*3.8 | 2500 |

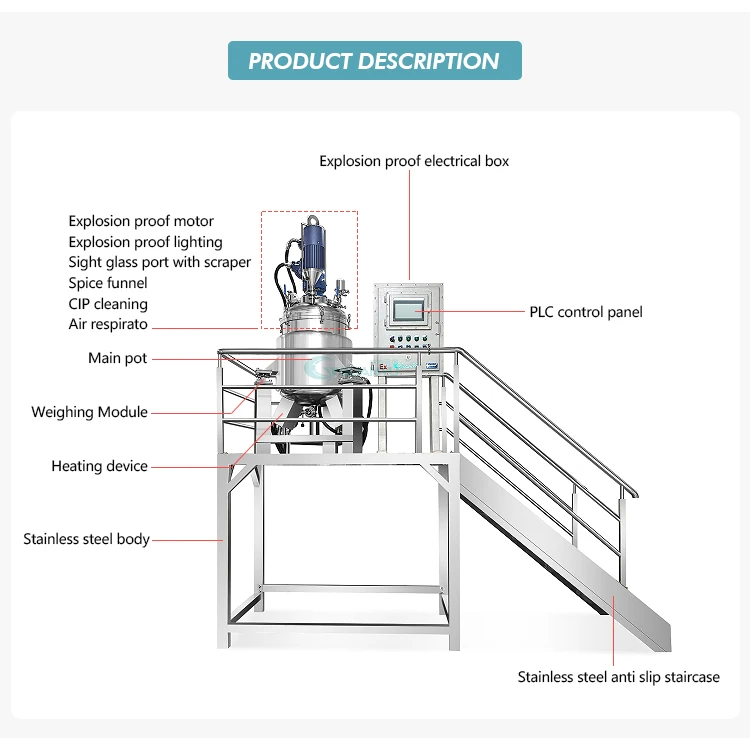

Stainless Steel Mixing Tank has mixing agitator,bottom homogenizer,stainless steel jacket tank shell,motor,electric control box,operation platform,staircase,etc.

◭The scraper type agitator mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve

many indissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period. High Shear Homoegnizer adopts German Technology, 0~3500rpm variable speed, and maximumspeed can reach to 4500rpm,the shear degree is about 0.2~5um.

◭The tank body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing or matte finish , which fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

◭We can choose PLC automatic control system ,or manual button control box,it depends upon your demand.

Mixing paddle

Explosion proof motor

Weighing Module

Discharge

the PLC panel

Explosion proof electrical box

The shell is made of stainless steel die-casting, with high-pressure electrostatic spraying on the surface. The switch adopts a brand new control mechanism, and PLC touch screen control is used to control the valve switch, equipment temperature, mixing speed and working time in real-time

Reviews

There are no reviews yet.