1000l Open Lid Liquid Soap Making Machine Professional Dishwashing Shampoo Mixer Liquid Detergent Mixer With Steam Generator

Products Description

Model | Effective | Stirring power and speed | Homogeneous power and speed | Heating power | |||

Capacity | KW | R/MIN | KW | R/MIN | Electric heating | Steam heating | |

GY-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6KW | Steam heating energy conservation and environmental protection, selected according to need |

GY-100 | 100 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GY-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GY-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

GY-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

GY-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27KW | |

GY-1000 | 1000 | 4 | 0-65 | 7.5 | 3600 | 36KW | |

GY-1500 | 1500 | 4 | 0-65 | 11 | 3600 | 45KW | |

GY-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | Recommend steam heating | |

GY-3000 | 3000 | 7.5 | 0-65 | 15 | 3600 | ||

GY-5000 | 5000 | 11 | 0-65 | 22 | 3600 | ||

The parameters for reference ONLY, all the machines can be customized accordingly. |

The heating and homogenizing mixing tank is mainly suitable for mixing and mixing different materials, mutual mixing anddissolving of mucus, etc. This machine is mainly suitable for liquid detergents (dishwasher, shampoo, shower gel, anti-dandruff shampoo, soap, car wash , Laundry detergent, essence, conditioner, etc.) product configuration. Jacketed electric heating hot water circulation heat transfer, has the characteristics of large heating area, high thermal efficiency, uniform heating, short boiling time of liquid material, and easy control of heating temperature. This equipment has the function of fast homogenization and emulsification, and has the advantages of good homogenization and emulsification (emulsification fineness of 1μm), etc., which greatly shortens the production cycle and saves energy consumption. It integrates heating, stirring, emulsification, temperature control, discharging, operation platform, electric control, etc. It is an ideal equipment for production and processing in the chemical, daily chemical, food, and industries.

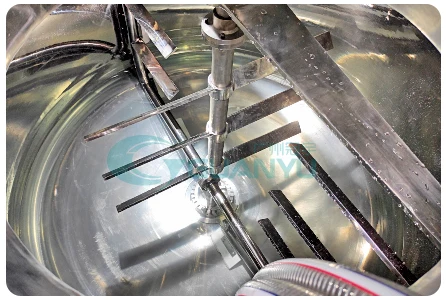

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

Transportation

Equipped with a lifting platform, which

can be used to transport heavy materials

to the platform for the next operation.

can be used to transport heavy materials

to the platform for the next operation.

Console

The control panel displays and controls

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

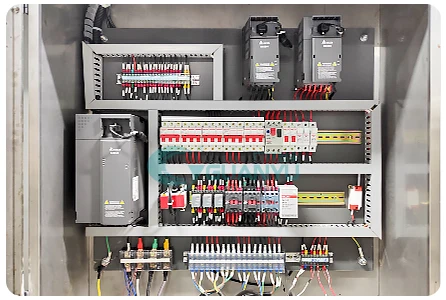

Electric box

Use internationally renowned brand

components to ensure the quality of the

equipment and longer service life

components to ensure the quality of the

equipment and longer service life

Service

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

Product configuration

About Us

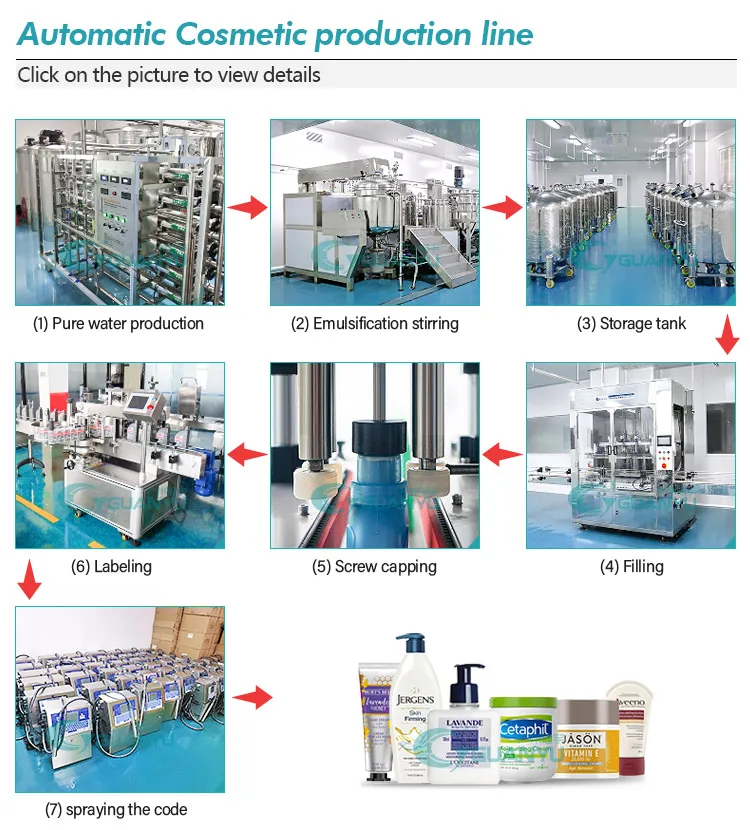

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.