100-5000L Liquid Soap Making Machine Cream Liquid Soap Shampoo Mixer 500 Kg Per Hour Liquid Soap Manufacturing Plant

Products Description

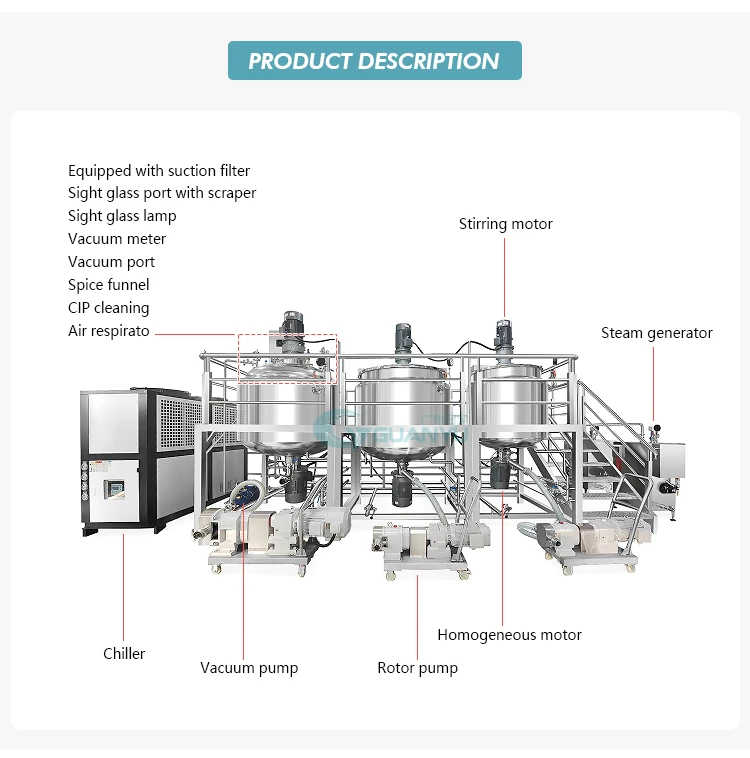

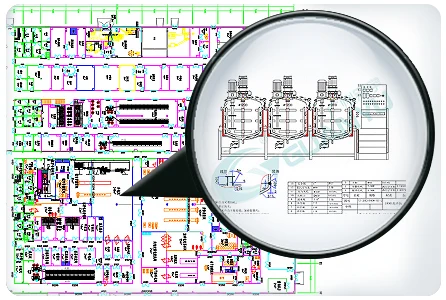

500 Kg Per Hour Liquid Soap Manufacturing Plant 200-5000L Liquid Soap Making Machine Cream Liquid Soap Shampoo Mixer

Model | Volume(L) | Blending power(kw) | Blending rotation speed(r/min) | Homogenizing power(kw) | Homogenizing rotation speed(r/min) | Heating method |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Steam heating Or Electric heating |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

lotion making machine/ steel mixer/ cosmetic mixer/ detergent making machine/ machines for to make shampoo/ soap making machine price/ liquid soap machine/ cosmetic manufacturing machinery

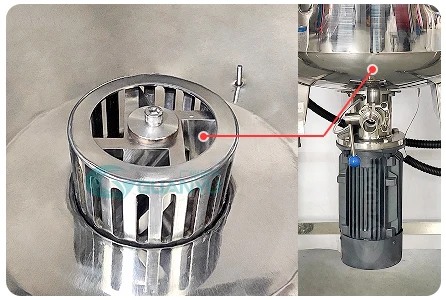

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Heating device

Electric heating or steam heating can be selected, and the material is heated through the interlayer to achieve the ideal

stirring and emulsification state.

stirring and emulsification state.

Chiller

The chiller can quickly cool water or other liquids to form a low-temperature water circulation system, which can accurately control the temperature required for production, with low noise and stable operation.

Vacuum Pumps

Under the vacuum environment, the emulsification pot can discharge foam when the materials are mixed, thus improving the quality of the materials to be treated. Vacuum deaeration process can ensure the sterility of materials

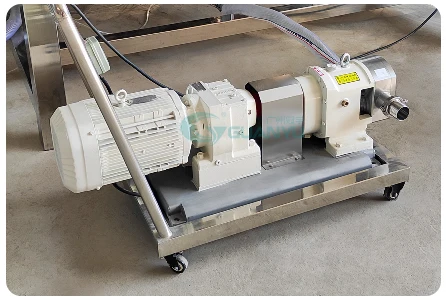

Rotor pump

The rotor pump is suitable for transporting high-viscosity paste or liquid. It can be transported from the mixing pot to the storage tank, or the raw materials can be transported to the mixing pot.

Console

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, etc.

working timing, vacuum extraction, interlayer heating, etc.

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Collette –

If you are going for finest contents like I do, simply

go to see this web page everyday as it provides quality contents, thanks!

Federico –

Hello! Do you know if they make any plugins to assist with SEO?

I’m trying to get my website to rank for some targeted keywords but I’m

not seeing very good results. If you know of any please share.

Cheers! I saw similar text here: Warm blankets

Lamentos –

Dinle: Sevgileri Yarınlara Bıraktınız Türkçe Rap Beat

Ask Travel Thailand –

It’s always a pleasure to come across such detailed and comprehensive explanations about traveling. Your expertise shines through, and I feel lucky to have access to your knowledge. A similar topic about adventure travel was discussed on TravelForums. Thank you so much for sharing!

m3 insert somun –

en kaliteli çakma somun çakma somun. Altınkaya.

Vicente –

Hello there! Do you know if they make any plugins to help with Search Engine

Optimization? I’m trying to get my blog to rank for some

targeted keywords but I’m not seeing very good gains.

If you know of any please share. Appreciate it! You

can read similar blog here: Change your life

yazıcı avukatlık –

en uygun insert somun insert somun. Altınkaya.

ruhların etiketi spotify –

en iyi instrumental hiphop albüm Ruhların Etiketi Spotify. Lamentos

user-010768 –

awesome

Edward –

Hey! I know this is kind of off topic but I was wondering if you knew

where I could find a captcha plugin for my comment form?

I’m using the same blog platform as yours and I’m having problems

finding one? Thanks a lot!

Here is my page; read this article

Clayton –

It’s an awesome article in favor of all the internet visitors; they

will obtain benefit from it I am sure.

My web site you could try this out

Reinigung für Büro München –

Die Grundreinigung wurde gründlich und mit Liebe zum Detail gemacht

Josie –

I am regular reader, how are you everybody? This article posted at

this site is actually fastidious.

my web site: take a look at the site here

Aurora –

What’s up i am kavin, its my first occasion to commenting anywhere, when i read this

article i thought i could also make comment due to this brilliant paragraph.

My blog post: get more information

Colette –

Very shortly this web site will be famous amid all blog people, due to it’s fastidious articles

my blog :: find out here

Ethel –

This is really fascinating, You’re an overly skilled blogger.

I’ve joined your feed and sit up for seeking more of your great post.

Also, I’ve shared your web site in my social networks

Look at my web blog; top article

Earl –

If some one wants to be updated with latest technologies after that he must be pay a visit this web page and

be up to date every day.

Feel free to visit my homepage – top article

Sylvester –

Hello, this weekend is pleasant in favor of me, because this moment i

am reading this wonderful informative article here at my home.

Feel free to surf to my webpage – more info here

Houston –

Nice post. I learn something totally new and challenging on sites I stumbleupon on a daily basis.

It’s always useful to read content from other writers and practice something from other web sites.

Here is my web site … why not try here