Producing syrup involves several intricate steps that require precision and the right equipment. Among these, the mixing kettle plays a pivotal role in ensuring the syrup’s quality and consistency. This article delves into the detailed process of producing syrup, the selection of appropriate machinery, and the advantages of using mixing kettles in syrup production.

The Syrup Production Process

1. Ingredient Preparation

The first step in syrup production is preparing the ingredients. The main components include:

- Sugar: This can be in the form of white granulated sugar or glucose.

- Water: Pure water is essential for dissolving the sugar.

- Additives: These can include preservatives, colorants, and flavorings, depending on the type of syrup being produced.

2. Dissolution

The next step involves dissolving the sugar in water. The sugar and water are added to the mixing kettle in precise proportions. The mixing mechanism of the kettle is activated to ensure the sugar dissolves completely in the water, forming a uniform solution.

3. Heating

Once the sugar is dissolved, the solution is heated. The mixing kettle’s heating system is turned on to bring the solution to the desired temperature, usually above 100°C. This heating process is crucial as it helps in further dissolving the sugar and beginning the concentration process.

4. Concentration

During the concentration phase, continuous heating and stirring are maintained. The aim is to evaporate the water content gradually, thereby increasing the concentration of the syrup. This step requires precise temperature control to prevent the sugar from caramelizing or burning.

5. Addition of Additives

As the syrup reaches the desired concentration, various additives like preservatives, colorants, and flavorings are introduced. These are thoroughly mixed to ensure even distribution throughout the syrup. The choice and quantity of additives depend on the specific type of syrup being produced.

6. Cooling

The final step is cooling the syrup to room temperature. This can be done by simply allowing the syrup to cool down naturally in the kettle or by using a cooling system if the production scale requires it. Once cooled, the syrup is ready for packaging or storage.

Choosing the Right Machinery

1. Mixing Kettle

The mixing kettle is the heart of the syrup production process. When selecting a mixing kettle, several factors need to be considered:

- Material: Stainless steel is the preferred material due to its durability, resistance to corrosion, and ease of cleaning.

- Capacity: The capacity of the kettle should match the production scale. Larger production volumes require kettles with higher capacities.

- Heating Method: Mixing kettles can be heated using electricity, steam, or thermal oil. The choice depends on the production requirements and available resources.

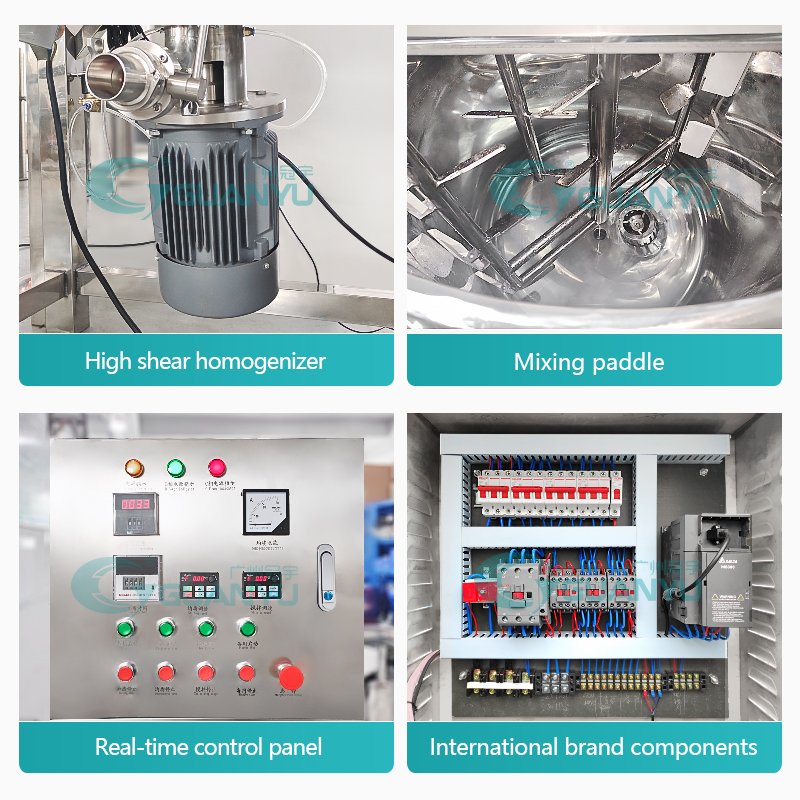

- Mixing Mechanism: The mixing kettle should have adjustable mixing speeds and different types of mixing paddles to ensure thorough mixing.

2. Temperature Control System

A precise temperature control system is essential for maintaining the desired temperature throughout the production process. This ensures that the syrup is heated evenly and prevents overheating or burning.

3. Automation and Control System

Modern syrup production benefits significantly from automation. Automated control systems can program and monitor the entire production process, reducing manual intervention, increasing efficiency, and ensuring consistent product quality.

Advantages of Using Mixing Kettles

1. Uniform Mixing

Mixing kettles are designed to ensure uniform mixing of ingredients. This uniformity is critical in preventing inconsistencies in the syrup’s texture and taste. The mixing mechanism allows the sugar to dissolve completely and the additives to distribute evenly.

2. Even Heating

The advanced heating systems in mixing kettles provide even heating, which is essential to avoid localized overheating. Uneven heating can cause parts of the syrup to caramelize or burn, affecting the final product’s quality. Even heating ensures that the entire batch of syrup reaches the desired temperature uniformly.

3. Efficient Production

Automated mixing kettles enhance production efficiency by reducing the need for constant manual monitoring and adjustments. This not only saves labor costs but also increases production speed. The automated control systems ensure that the process follows the set parameters, resulting in a consistent and high-quality product.

4. Ease of Cleaning

Stainless steel mixing kettles are easy to clean and maintain, which is crucial for maintaining hygiene standards in food production. The smooth surface of stainless steel prevents residues from sticking, making the cleaning process straightforward and effective.

5. Strong Controllability

Mixing kettles offer excellent controllability over the production process. With precise temperature and mixing speed controls, manufacturers can fine-tune the process to achieve the desired syrup consistency and quality. This level of control is vital for producing syrups with specific characteristics.

Conclusion

The production of syrup is a meticulous process that requires careful attention to detail and the right equipment. The mixing kettle, with its ability to ensure uniform mixing and even heating, plays a central role in producing high-quality syrup. By choosing the appropriate machinery and utilizing advanced control systems, manufacturers can enhance production efficiency, maintain consistent product quality, and meet the demands of the market. The advantages of using mixing kettles, from efficient production to ease of cleaning, make them an indispensable part of the syrup production process.

This piece of writing is actually a nice one it helps new web visitors, who are wishing

in favor of blogging.

Also visit my page :: nordvpn coupons inspiresensation

excellent put up, very informative. I’m wondering why the opposite experts of this sector don’t notice this.

You should proceed your writing. I am sure, you have a great readers’ base already!

Here is my website; eharmony special coupon code 2025

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is

added I get several emails with the same comment. Is there any

way you can remove me from that service? Many thanks!

Feel free to surf to my homepage … vpn

I go to see each day a few sites and information sites to

read articles, except this blog gives feature based articles.

https://tinyurl.com/27xe7che gamefly

Good post! We will be linking to this great post on our website.

Keep up the great writing.

You’ve made some decent points there. I looked on the net for additional information about the issue and found most individuals will go along with your views on this website.

For hottest news you have to pay a visit web and on world-wide-web I found this web site as a

best web page for most recent updates. https://tinyurl.com/ypubsnjg eharmony special coupon code

2025

Alright, so I checked out u88vn… not bad! Got a decent selection of games and the site seems pretty solid. Nothing *too* flashy, but it gets the job done. Definitely worth a look if you’re hunting around for a new spot to play. Check it out here: u88vn

Hi there everyone, it’s my first pay a quick visit at this web page, and

piece of writing is really fruitful for me, keep up posting these content.

https://www.highlandguides.com/ vpn

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.info/register-person?ref=IXBIAFVY