Perfume production line is an intricate process that involves the precise combination of fragrances, solvents, and alcohol to create a product that is both aesthetically pleasing and commercially viable. This production process requires a well-organized assembly line that includes specialized equipment such as manufacturing units, filling machines, capping systems, and labeling devices. One of the critical aspects of this production line is ensuring safety, especially given the flammable nature of many of the components involved. Therefore, implementing explosion-proof designs in the manufacturing and filling equipment is essential to protect both the product and the workforce.

Perfume Manufacturing Equipment: The Heart of the perfume Production Line

The perfume manufacturing process begins with the precise blending of various ingredients, including essential oils, alcohol, and water. These ingredients are combined in carefully controlled ratios to produce the desired fragrance. The primary equipment used in this stage includes mixing tanks, agitators, and temperature control systems.

Explosion-Proof Design in Manufacturing Equipment

Given that alcohol, a primary ingredient in most perfumes, is highly flammable, the risk of explosion is a significant concern in perfume production facilities. To mitigate this risk, the manufacturing equipment is designed with explosion-proof features. These features include:

- Sealed Mixing Tanks: The mixing tanks are designed to be hermetically sealed to prevent the escape of volatile fumes. This containment is crucial as it minimizes the risk of vapor buildup in the production area, which could lead to an explosion if ignited.

- Intrinsically Safe Electronics: All electronic components used in the manufacturing equipment are designed to be intrinsically safe. This means they are engineered to operate at low energy levels that are incapable of igniting flammable vapors, even in the event of a fault. This safety feature is vital in preventing accidental sparks that could trigger an explosion.

- Ventilation Systems: Proper ventilation is a key aspect of explosion prevention. The manufacturing area is equipped with specialized ventilation systems that ensure the continuous removal of flammable vapors from the production environment. These systems are often equipped with sensors that monitor vapor levels and automatically adjust airflow to maintain safe conditions.

- Temperature and Pressure Controls: The temperature and pressure within the mixing tanks are carefully monitored and controlled. Overheating or over-pressurization can lead to dangerous conditions, so the equipment is fitted with safety valves and automatic shut-off systems that activate if thresholds are exceeded.

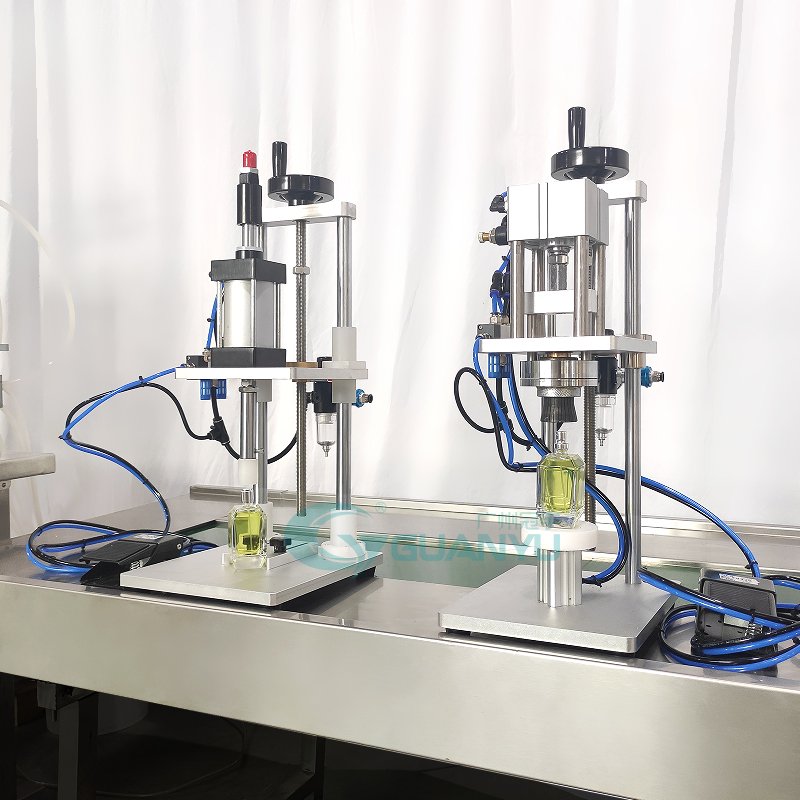

Filling Equipment: Precision and Safety in Action

Once the perfume is blended, it is ready to be transferred into individual bottles. The filling process is one of the most delicate stages in perfume production, requiring precision to ensure each bottle contains the exact volume of product. This stage also involves significant safety considerations due to the potential for spills and vapor releases.

Explosion-Proof Design in Filling Equipment

Just like the manufacturing equipment, the filling equipment is also designed with explosion-proof features to ensure safety. The explosion-proof design in filling equipment includes several critical elements:

- Controlled Environment Filling Stations: The filling machines operate within controlled environments where temperature, humidity, and pressure are regulated to minimize the risk of vapor ignition. These environments often include cleanroom standards to reduce the presence of particles that could cause friction and potentially ignite flammable vapors.

- Non-Sparking Materials: The materials used in the construction of filling machines are carefully selected to prevent sparking. For example, components that come into direct contact with the perfume or its vapors are made from non-sparking materials such as stainless steel, brass, or certain types of plastic. These materials are chosen for their ability to resist corrosion and static charge buildup, both of which are crucial in preventing explosions.

- Automatic Shut-Off Systems: The filling equipment is equipped with sensors that detect leaks, spills, or any other anomalies that could lead to a hazardous situation. If any such condition is detected, the system automatically shuts down to prevent escalation. This feature is particularly important in preventing the accumulation of flammable liquids or vapors in the filling area.

- Explosion-Proof Motors and Components: The motors and other electrical components used in the filling equipment are designed to be explosion-proof. These components are enclosed in housings that prevent any sparks from escaping and coming into contact with flammable vapors. Additionally, the wiring is typically run through conduits that are resistant to fire and explosion, providing an additional layer of safety.

Capping and Labeling Equipment: Ensuring Integrity and Brand Identity

After the perfume is filled into bottles, the next steps involve sealing the bottles with caps and applying labels. These processes are less hazardous compared to manufacturing and filling but are still critical for ensuring the integrity and marketability of the final product.

Safety Considerations in Capping Equipment

Capping machines must ensure that the caps are tightly sealed to prevent any leakage of the perfume. While this process is generally straightforward, safety features are still necessary:

- Non-Sparking Components: Similar to filling equipment, capping machines often use non-sparking materials, especially in parts that come into contact with the bottle caps. This precaution is necessary to prevent any accidental ignition of vapors that might have escaped during the filling process.

- Torque Control Systems: The capping equipment is equipped with torque control systems that ensure the caps are applied with the correct amount of force. Too much torque could damage the bottle or the cap, leading to leaks, while too little torque might result in a poor seal. Proper torque control also minimizes the risk of creating sparks during the capping process.

Labeling Equipment and Explosion Safety

Labeling machines apply branding and product information to the bottles. While the risk of explosion is low during this stage, there are still safety protocols in place:

- Static Electricity Control: Labeling equipment is designed to minimize the buildup of static electricity, which could potentially ignite flammable vapors. This is achieved through grounding systems and the use of antistatic materials.

- Non-Heating Adhesives: The adhesives used in labeling are chosen for their non-heating properties, meaning they do not require high temperatures to bond labels to bottles. This is important to prevent any unnecessary heat generation that could lead to ignition.

Comprehensive Safety Management in Perfume Production

While the equipment itself is designed with numerous safety features, managing a perfume production line also requires adherence to strict safety protocols. These protocols include regular maintenance of equipment, employee training, and emergency preparedness.

- Regular Equipment Maintenance: To ensure that all safety features are functioning correctly, regular maintenance is essential. This includes checking the integrity of explosion-proof enclosures, testing ventilation systems, and verifying the operation of automatic shut-off valves. Any issues identified during maintenance must be promptly addressed to prevent potential hazards.

- Employee Training: Employees working on the perfume production line must be trained in handling flammable materials and operating explosion-proof equipment. This training includes understanding the risks associated with the materials used, recognizing the signs of equipment malfunction, and knowing the procedures to follow in an emergency.

- Emergency Preparedness: Despite all precautions, the possibility of an accident cannot be entirely eliminated. Therefore, having a robust emergency response plan is crucial. This plan should include evacuation procedures, fire suppression systems, and coordination with local emergency services.

Conclusion

The production of perfume is a complex and delicate process that requires the integration of various sophisticated machines, each designed to perform specific functions efficiently. However, due to the flammable nature of the ingredients used in perfume production, safety is a paramount concern. By incorporating explosion-proof designs into manufacturing and filling equipment, perfume manufacturers can significantly reduce the risk of accidents, ensuring the safety of their workers and the integrity of their products.

Implementing these advanced safety features requires not only careful design and engineering but also a commitment to regular maintenance, employee training, and emergency preparedness. As the perfume industry continues to grow, the adoption of these safety measures will be essential in maintaining high standards of production while safeguarding human life and property.

Welcome to contact us!

WhatsApp: +8613825066178 (Phone/WhatsApp/WeChat)

+8613925109966

Email: :info@guanyugz.com/ info@guanyumixer.com

Website: https://guanyumixer.com https://guanyugz.com

Brazino777app, eh? Sounds spicy! Always looking for a new place to try my luck. Hope it’s as fun as it sounds. Good luck everyone! Check it out here: brazino777app

Alright, gv777vipgame, lemme tell ya. VIP treatment is alright. Games load quick and the graphics are nice. Could use some more variety in the slots though But overall, I’m enjoying it Try your luck today! gv777vipgame

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://accounts.binance.com/fr/register?ref=T7KCZASX

Yo, royal8888logo has a fantastic variety of jackpot slots! I’ve seen a number of jackpots dropped here already. Give it a shot royal8888logo

bd678bet, alright! Giving it a spin. They got a nice range of bets. Could be my new hangout. Check it out for yourself. bd678bet

555okmexico, yeah! This one feels good. All the right games are here. This site is decent. You might like it. 555okmexico