Meilleurs choix pour 2025 inclure le mélangeur émulsifiant sous vide de Guanyu, Mélangeur industriel PerMix V, Mélangeur Ross industriel, Mélangeur industriel IKA, Mélangeur industriel INDCO, et malaxeur par lots de Changzhou. Les clients recherchent des mélangeurs industriels de haute qualité, novateur, et fiable. Les acheteurs veulent des mélangeurs industriels qui fournissent systématiquement d'excellents résultats et qui sont polyvalents pour diverses applications.. Les meilleurs mélangeurs industriels disposent désormais d'une technologie avancée et de fonctions spécialisées, aider chaque secteur à atteindre des performances et une efficacité exceptionnelles à chaque fois.

Principaux à retenir

Le marché des malaxeurs industriels connaît une croissance rapide. C'est parce que de plus en plus de gens les veulent nourriture, produits de beauté, produits chimiques, et pharmaceutiques. Nouvelle technologie comme les commandes intelligentes, Capteurs IoT, et l'automatisation aide à améliorer le mixage. Cela permet également d'économiser de l'énergie et d'accélérer le travail. Meilleures marques comme Guanyu, PÉRIX, Ross, IKA, INDCO, et Changzhou font de bonnes machines. Ces machines ont des fonctionnalités pour différents travaux et besoins. Le choix du bon mélangeur dépend du travail pour lequel vous en avez besoin. Vous devriez également penser à combien vous devez gagner, comme c'est facile à utiliser, et dispositifs de sécurité. Cela vous aide à obtenir de bons résultats à chaque fois. Une maintenance et une formation régulières aident les machines à bien fonctionner. Ils aident également les machines à durer plus longtemps.

Tendances industrielles des mélangeurs

Croissance du marché

Le marché des malaxeurs industriels s’agrandit. De nombreuses industries veulent de meilleures machines pour un travail plus rapide et de meilleure qualité. Voici quelques raisons pour lesquelles le marché se développe:

Production alimentaire ça monte. L'Organisation des Nations Unies pour l'alimentation et l'agriculture affirme que ce sera 70% plus élevé de 2050. Cela signifie que davantage de mélangeurs sont nécessaires pour la transformation des aliments..

Le cosmétiques et soins personnels l'industrie se développe à 4.5% chaque année à partir de 2024 à 2032. Cela fait que de plus en plus de personnes ont besoin de solutions industrielles de mélangeurs pour les recettes délicates..

Chimique, pharmaceutique, et les entreprises de traitement de l'eau ont besoin de mélangeurs avancés pour plus de sécurité et de précision..

L’Asie-Pacifique construit davantage d’usines, surtout en Chine et en Inde. Cela incite davantage de personnes à utiliser la technologie de mélange industriel.

L'Amérique du Nord et l'Europe continuent de croître parce qu'elles ont des règles strictes en matière de qualité et de sécurité..

Aspect | Détails |

|---|---|

Évaluation marchande (2025) | |

TCAC (2025-2032) | 6.1% |

Type de produit leader | Agitateurs (29.2% part de marché dans 2025) |

Principaux secteurs verticaux des utilisateurs finaux | Produits chimiques, nourriture & boisson, médicaments, eau & eaux usées, produits pétrochimiques |

Leaders du marché régional | Amérique du Nord, Asie-Pacifique, Europe |

Les mélangeurs industriels sont importants dans ces domaines. Ils aident à mélanger les choses de la même manière à chaque fois. Ils travaillent également rapidement et donnent de bons résultats.

Avancées technologiques

Les nouvelles technologies changent le fonctionnement du mélange industriel. Les entreprises dépensent de l'argent pour améliorer les produits industriels des mélangeurs et résoudre de nouveaux problèmes.

La modélisation des jumeaux numériques permet de voir et de tester le mixage en temps réel. Les opérateurs peuvent essayer des changements sans arrêter les machines.

Les capteurs IoT et l'analyse cloud rendent les mélangeurs intelligents. Ces mélangeurs peuvent se vérifier, avertir des réparations, et changer leur façon de fonctionner si nécessaire.

Les conceptions économes en énergie utilisent de nouvelles formes de turbine et des revêtements spéciaux. Ceux-ci aident à arrêter les dommages et à prolonger la durée de vie des mélangeurs..

Les plates-formes d'automatisation relient les mélangeurs aux systèmes ERP. Cela aide les gens à voir ce qui se passe et accélère le travail..

Les mixeurs dynamiques deviennent de plus en plus populaires. Ils conviennent aux travaux qui nécessitent un contrôle minutieux et une haute qualité.

Note: Le 2025 Tarifs américains ont changé les chaînes d'approvisionnement. Les entreprises utilisent désormais de nouvelles façons d'obtenir des pièces et de fabriquer des malaxeurs industriels.

De nouvelles idées en matière de technologie de mélange aident les mélangeurs industriels à rester utiles, fonctionne bien, et sois prêt pour la suite.

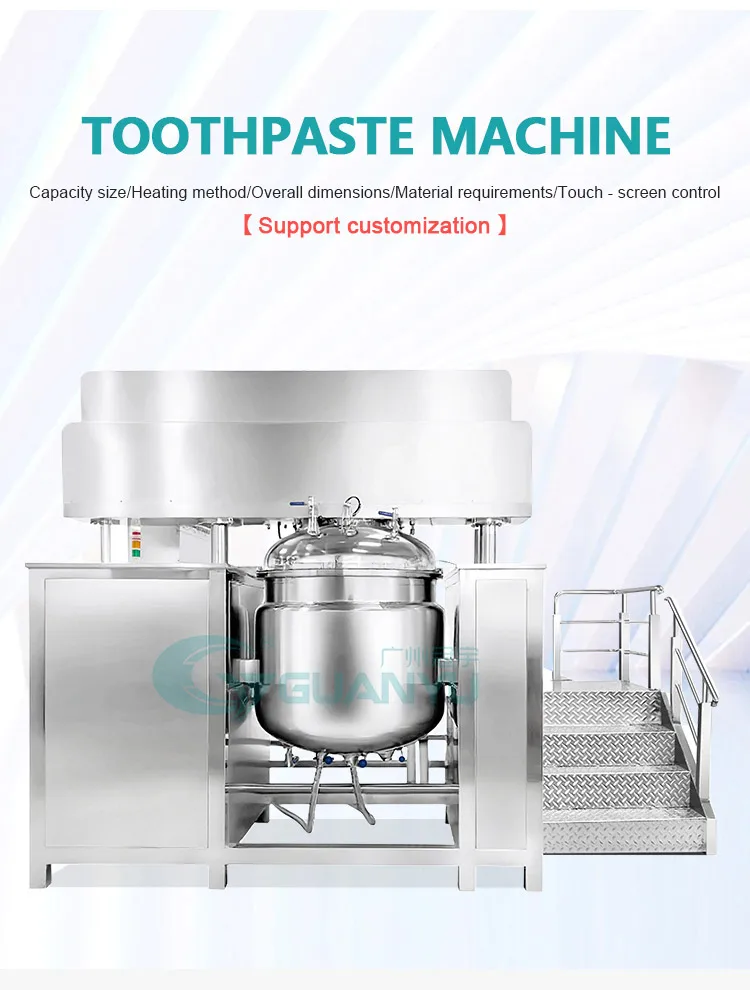

Mélangeur émulsifiant sous vide de Guanyu

Aperçu

Machines Cie. de Guangzhou Guanyu., Ltée. est une entreprise leader dans le domaine des mélangeurs. L'entreprise a débuté en 1987. Maintenant, cela aide les clients du monde entier. Guanyu fabrique des mélangeurs puissants pour les cosmétiques, médecine, nourriture, et une nouvelle énergie. Le mélangeur émulsifiant sous vide montre que Guanyu se soucie de la qualité et des nouvelles idées. Ce mixeur utilise technologie intelligente. Cela donne des résultats stables et fonctionne bien à chaque fois.

Caractéristiques

Utilise une émulsification sous vide pour un mélange minutieux

Peut être modifié pour s'adapter à différents travaux

Fabriqué en acier inoxydable pour durer longtemps

Possède des commandes faciles à utiliser

Économise de l'énergie pour aider à réduire les factures

Possède de nombreuses pièces de sécurité

Livré avec une garantie de deux ans et une aide à vie

L'équipe de Guanyu aide à installer le mixeur et enseigne aux gens comment l'utiliser. Les clients reçoivent de l'aide à tout moment pour que le mélangeur continue de fonctionner correctement..

Applications

Le mélangeur émulsifiant sous vide fonctionne dans de nombreux domaines. Les fabricants de cosmétiques l'utilisent pour les crèmes, lotions, et gels. Les sociétés pharmaceutiques l’utilisent pour les onguents et les suspensions. Les fabricants de produits alimentaires l'utilisent pour mélanger les sauces et les vinaigrettes. Il permet également de fabriquer de nouveaux matériaux énergétiques.

Pros

Fabrique des produits toujours bons

Peut être modifié pour des besoins spéciaux

Utilise les nouvelles technologies pour mieux travailler

Donne une grande aide et une formation après l'achat

A des récompenses ISO9001 et de haute technologie

Points forts | Détails |

|---|---|

Qualité | Matériaux solides et bonne construction |

Technologie | Nouveaux systèmes de mélange et de contrôle |

Performance | Fonctionne bien, rapide, et avec soin |

Inconvénients

Certaines personnes peuvent avoir besoin de cours supplémentaires pour utiliser les commandes.

Mélangeur PerMix V

Aperçu

PerMix est une entreprise leader dans la technologie des mélangeurs. La société commencé dans les années 1950 et aide maintenant les gens du monde entier. PerMix fabrique des mélangeurs v et en propose de nombreux choix de mélangeurs. Leurs machines de mélange v sont connues pour être bonnes, fiable, et nouveau. PerMix est bien connu sur le marché des équipements de mélange industriel. De nombreuses entreprises font confiance à PerMix pour un excellent mélange et des résultats stables..

Caractéristiques

PÉRIX v machines à mélanger avoir une chambre en forme de V pour un meilleur mélange. Ces mélangeurs en V peuvent mélanger sous vide et sont dotés de vestes pour contrôler la température.. Les gens peuvent choisir parmi plusieurs tailles, des petites unités de laboratoire aux grandes machines de mélange de 6 000 litres. PerMix fabrique des mélangeurs v à partir de 304 ou 316 acier inoxydable, et parfois de l'Hastelloy, pour répondre aux règles GMP. L'entreprise vend des mélangeurs V qui permettent d'économiser de l'argent et ont des conceptions intelligentes. Chaque machine de mélange v peut être modifiée pour des travaux spéciaux, donc ils travaillent pour de nombreuses industries.

PerMix offre un support client solide et un service mondial. Cela aide les utilisateurs à tirer le meilleur parti de chaque machine de mixage V..

Applications

Les mélangeurs PerMix v sont utilisés dans de nombreux domaines. Les sociétés pharmaceutiques utilisent le mélange V pour les poudres et les granulés. Les fabricants de produits alimentaires utilisent des mélangeurs V pour les épices, saveurs, et additifs. Les usines chimiques utilisent des mélangeurs V pour mélanger des poudres fines et des matériaux spéciaux. Le processus de mélange v donne de bons résultats et des performances constantes à chaque fois.

Pros

Donne une efficacité élevée et un mélange uniforme

De nombreux mélangeurs V pour différents travaux

Les options du mélangeur peuvent être modifiées

Connu pour sa bonne qualité et ses nouvelles idées

Les malaxeurs V économisent de l'argent et bénéficient d'une aide mondiale

Avantage | Description |

|---|---|

Performance | Constant, mélange fiable |

Qualité | Matériaux solides et conception soignée |

Rentable | Bons prix pour les mixeurs V |

Inconvénients

Certaines personnes peuvent avoir besoin de plus d'espace et planifier l'installation de grosses machines de mixage.. Un nettoyage est souvent nécessaire pour maintenir une qualité et des performances élevées.

Mélangeur Ross

Aperçu

Ross est une entreprise leader dans le domaine des équipements de mélange. L'entreprise a commencé plus de 180 il y a des années. Maintenant, Ross vend des mélangeurs à plus de 50 des pays. Les gens connaissent Ross pour être fiable et créatif. Ross fabrique des mélangeurs pour produits chimiques, médecine, nourriture, et les plastiques. Leurs ingénieurs travaillent avec les clients pour résoudre différents problèmes de production.

Caractéristiques

Les mélangeurs Ross ont de nombreuses fonctionnalités utiles. Certains modèles peuvent effectuer un mélange à cisaillement élevé et fonctionner sous vide. Ils utilisent l'acier inoxydable, ils durent donc longtemps et sont faciles à nettoyer. Certains mélangeurs ont des lames que vous pouvez changer pour différentes tâches. Ross propose également des options de contrôle de la température et d'alimentation automatique des ingrédients..

Conseil: Ross propose des petits et grands mélangeurs. Cela aide les entreprises à fabriquer davantage de produits à mesure qu'elles se développent.

Fonctionnalité | Description |

|---|---|

Mélange les choses rapidement et uniformément | |

Réduit les bulles d’air et l’oxydation | |

Personnalisation | Conçu pour des usages spéciaux |

Applications

Les mélangeurs Ross sont utilisés dans de nombreux domaines. Les usines chimiques les utilisent pour les adhésifs et les mastics. Les entreprises alimentaires les utilisent pour les sauces et les pâtes à frire. Les sociétés pharmaceutiques les utilisent pour les crèmes et les gels. Ces machines participent également à la fabrication de cosmétiques et de plastiques.

Pros

De nombreux choix de mélangeurs

Connu pour être fiable

Conceptions personnalisées pour des besoins spéciaux

Assistance et service dans le monde entier

Facile à nettoyer

Inconvénients

Certains mélangeurs Ross coûtent plus cher au début. Les gens peuvent avoir besoin d'une formation pour utiliser les commandes.

Mélangeur IKA

Aperçu

IKA est une entreprise leader dans le domaine des mélangeurs. Il est connu dans le monde entier. De nombreuses personnes font confiance à IKA pour sa fiabilité mélangeurs. Ces machines sont utilisées en médecine, produits chimiques, et la biologie. IKA fabrique des équipements nouveaux et utiles. Ils ont des machines régulières et spéciales. Ces mélangeurs fonctionnent dans les laboratoires et les grandes usines. Les conceptions IKA aident les gens à obtenir des résultats précis. Ils travaillent avec de petites ou de grandes quantités.

Caractéristiques

Les mélangeurs IKA sont dotés de commandes intelligentes et peuvent être configurés de différentes manières. Beaucoup ont des écrans qui affichent des chiffres et vous permettent de définir des programmes. Certains peuvent contrôler chauffer jusqu'à 250°C. Les gens peuvent choisir parmi de nombreux types, comme des agitateurs magnétiques, homogénènes, et agitateurs orbitaux. Le logiciel Labworldsoft vous permet d'exécuter jusqu'à 64 appareils à la fois. Vous pouvez enregistrer des données importantes et automatiser les expériences.

IKA apprend aux gens à utiliser et à entretenir leurs machines. Ils le font en personne ou en classe.

Équipement/caractéristique | Spécifications clés & Fonctions | Points forts de l'application |

|---|---|---|

Maintient la température stable, a un écran lumineux, utilise le PT 1000 capteurs | Bon pour fabriquer des médicaments et des API | |

Circulateurs à immersion à contrôle IC | Contrôle la chaleur jusqu'à 250°C | Utilisé pour chauffer des liquides chimiques et biologiques |

Agitateur numérique ROCKER 3D | Se déplace en 3D, la vitesse peut être modifiée | Utilisé pour le travail cellulaire et le mélange |

Contrôle du broyeur à tubes | Utilise une chambre que vous jetez | Empêche les germes de se propager |

Applications

Les malaxeurs IKA sont utilisés dans de nombreux travaux. Les laboratoires de médecine les utilisent pour fabriquer des médicaments et préparer des échantillons. Les entreprises chimiques les utilisent pour tester et vérifier la qualité. Les entreprises alimentaires et biotechnologiques utilisent les machines IKA pour mélanger et mélanger des matériaux doux. De nombreux produits IKA peuvent être modifiés pour différents travaux grâce à leur conception.

Pros

De nombreux modèles pour différents travaux

Commandes intelligentes et peut fonctionner seul

Des machines spéciales pour des besoins uniques

Bonne aide et formation

Facile à nettoyer

Inconvénients

Certaines machines de mixage IKA nécessitent un nouveau logiciel pour obtenir les meilleures fonctionnalités. Les gens auront peut-être besoin de plus de leçons pour utiliser tous les outils intelligents.

Mélangeur industriel INDCO

Aperçu

INDCO est une entreprise bien connue pour les malaxeurs. Cela a commencé dans 1975. Maintenant, il aide les clients en Amérique du Nord et ailleurs. INDCO fabrique des mélangeurs pour de nombreux types d'entreprises. Leur équipe travaille dur pour fabriquer des produits solides et sûrs. Ils ont de nombreuses années d'expérience. INDCO veut que chaque client soit satisfait de ses machines.

Caractéristiques

INDCO a de nombreux modèles de mélangeurs choisir parmi. Chacun a des fonctionnalités spéciales pour différents travaux. La plupart des mélangeurs utilisent de l'acier inoxydable, ils durent donc longtemps et sont faciles à nettoyer. Vous pouvez changer la vitesse pour mélanger les choses correctement. Certains mélangeurs ont des moteurs sans danger pour les endroits dangereux. INDCO vend également des mélangeurs que vous pouvez déplacer, mélangeurs à tambour, et mélangeurs à grande cuve. Les clients peuvent prendre l'air, électrique, ou entraînements hydrauliques.

Conseil: Les ingénieurs d'INDCO aident les gens à choisir le meilleur mélangeur pour leur travail. Ils peuvent également faire mélangeurs personnalisés pour des besoins spéciaux.

Fonctionnalité | Avantage |

|---|---|

Construction en acier inoxydable | Solide et simple à nettoyer |

Vitesse variable | Vous permet de contrôler la vitesse de mélange |

Options personnalisées | Conçu pour des travaux spéciaux |

Applications

Les mélangeurs INDCO sont utilisés dans de nombreuses entreprises. Les entreprises de peinture les utilisent pour mélanger les couleurs et les résines. Les fabricants de produits alimentaires utilisent les mélangeurs INDCO pour les sauces, pansements, et sirops. Les usines chimiques les utilisent pour mélanger des liquides et des poudres. Les usines de traitement de l'eau utilisent des mélangeurs INDCO pour bien mélanger les produits chimiques. INDCO aide également les entreprises de médecine et de cosmétiques.

Pros

De nombreuses tailles et types de mélangeurs

Focus sur la sécurité et les règles

Aide personnalisée des ingénieurs

Expédition rapide pour les mélangeurs réguliers

Service client rapide et utile

Inconvénients

Certains mélangeurs INDCO doivent être assemblés sur place. Les gens peuvent avoir besoin de leçons pour utiliser les commandes spéciales.

Mélangeur par lots de Changzhou

Aperçu

Changzhou est une entreprise bien connue dans le domaine des malaxeurs. Les gens font confiance à leurs malaxeurs par lots pour bien fonctionner. Ces machines aident les usines à mélanger beaucoup de matériaux en même temps. Vous pouvez trouver des mélangeurs par lots Changzhou dans le secteur chimique, nourriture, et plantes médicinales. L'entreprise fabrique des machines solides et qui fonctionnent toujours de la même manière.. Beaucoup de gens choisissent Changzhou parce qu'il offre un bon rapport qualité-prix..

Caractéristiques

Construction robuste: Changzhou utilise de l'acier inoxydable solide pour que les machines durent longtemps.

Capacité flexible: Les machines sont disponibles en petites et grandes tailles pour différents travaux.

Commandes conviviales: Les travailleurs peuvent modifier la vitesse et le temps avec des boutons simples.

Lames de mélange efficaces: Des lames spéciales aident à bien mélanger les poudres et les liquides.

Systèmes de sécurité: Les couvercles de sécurité et les boutons d'arrêt assurent la sécurité des travailleurs.

Entretien facile: Vous pouvez retirer des pièces pour les nettoyer et les réparer rapidement.

Conseil: Changzhou peut fabriquer des machines spéciales si les clients ont besoin de quelque chose de différent.

Applications

De nombreuses usines utilisent Mélangeurs par lots de Changzhou pour leur travail. Les usines chimiques les utilisent pour mélanger des poudres et des liquides. Les entreprises alimentaires les utilisent pour mélanger la pâte, sauces, et épices. Les sociétés pharmaceutiques utilisent ces mélangeurs pour fabriquer des comprimés et des crèmes. Les fabricants de peintures et de revêtements utilisent des machines Changzhou pour mélanger les couleurs.

Pros

De nombreuses tailles et types de machines parmi lesquelles choisir

Construit solidement pour durer longtemps

Facile à utiliser pour les nouveaux et les anciens travailleurs

Bon prix pour ce que vous obtenez

Peut être modifié pour des travaux spéciaux

Avantage | Description |

|---|---|

Versatilité | Peut mélanger de nombreux types de matériaux |

Fiabilité | Donne les mêmes résultats à chaque fois |

Soutien | Changzhou apporte son aide technique |

Inconvénients

Certains mélangeurs par lots de Changzhou ont besoin de plus d'espace dans des usines très fréquentées. Les travailleurs peuvent avoir besoin de leçons supplémentaires pour utiliser toutes les fonctionnalités. Certains modèles mettent plus de temps à arriver car beaucoup de gens les veulent.

Technologie des malaxeurs planétaires

Grandes marques

De nombreuses entreprises sont des noms de premier plan dans le domaine de la technologie des malaxeurs planétaires.. Ces marques sont connues pour leurs nouvelles idées et leur bonne qualité. Ils sont également forts sur le marché. Le tableau ci-dessous répertorie quelques grandes marques et ce qu'elles font le mieux dans différents endroits:

Présence sur le marché & Points forts | |

|---|---|

PÉRIX | Innovation, forte portée mondiale, solutions avancées de mixage v |

Charles Ross & Fils Compagnie | Large gamme de produits, leadership technologique, partenariats stratégiques |

Jaygo | Expansion mondiale, systèmes de mélange v axés sur le client |

Équipement de traitement Archem | R continu&D, options de mélange flexibles |

Fraisage personnalisé & Consultant | Innovation, des partenariats industriels solides |

Hockmeyer Equipment Corp.. | Leadership technologique, performances de mixage compétitives |

Robuste R&D, machines de mélange fiables | |

Société Thinky | Innovation centrée sur le client, extension de mixage globale v |

Note: PerMix et Ross ont changé le marché du mixage vidéo. Pour ce faire, ils utilisent les nouvelles technologies et écoutent les clients..

Caractéristiques clés

Les malaxeurs planétaires utilisent le mélange v pour donner des résultats stables. Ces machines ont souvent plus d'une lame de mélange. Cela aide à bien mélanger les poudres et les liquides. Les commandes programmables vous permettent de régler le temps et la vitesse de mélange. Les machines sont en acier inoxydable, Alors ils durent longtemps. Les systèmes de sécurité aident à assurer la sécurité des travailleurs pendant le mélange. La conception rend le nettoyage rapide et facile.

Nouvelle technologie apporte des choses comme automatisation et intelligence artificielle. Certaines machines peuvent être surveillées et contrôlées de loin. Ces fonctionnalités aident les entreprises à travailler plus rapidement et à maintenir le mixage à un niveau élevé..

Applications

De nombreuses industries utilisent des malaxeurs planétaires pour différents travaux. Le processus de mélange v est bon pour mélanger les poudres, pastes, et matériaux épais. Nourriture, médecine, chimique, et cosmétique les entreprises utilisent le mélange v pour fabriquer des produits uniformes. Les constructeurs électroniques et automobiles utilisent également le mélange V pour des matériaux spéciaux. Les malaxeurs V peuvent gérer facilement des petits et des gros lots.

Conseil: Les usines choisissent les malaxeurs planétaires car ils peuvent effectuer des travaux de mélange difficiles et donner toujours les mêmes résultats..

Mélangeur pharmaceutique

Principaux fabricants

L'industrie pharmaceutique a besoin de mélangeurs qui fonctionnent toujours bien. Certaines entreprises sont les meilleures dans la fabrication de ces machines.

SPX Corporation fabrique des mélangeurs de poudre dotés de conceptions de turbine intelligentes qui permettent d'économiser de l'énergie.

Charles Ross & Son Company dispose de nombreux mélangeurs pour petits et grands travaux.

Alfa Laval AB vend des mélangeurs très propres et respectant des règles strictes.

Sulzer SA. et Philadelphia Mixing Solutions utilisent des plates-formes de jumeaux numériques et l'IA pour aider à réparer les machines avant qu'elles ne tombent en panne. Ces entreprises sont les meilleurs choix pour les systèmes de mélange complets dans les usines de médicaments..

Ces entreprises dépensent de l'argent pour de nouvelles idées. Ils fabriquent davantage de machines et de nouveaux produits pour répondre au besoin de meilleurs systèmes de mélange..

Caractéristiques

Les mélangeurs pharmaceutiques doivent être précis et donner toujours les mêmes résultats. La plupart des endroits choisissent mélangeurs à montage fixe parce qu'ils sont faciles à utiliser avec d'autres machines.

Les fonctionnalités importantes sont:

Entraînements à vitesse variable pour un meilleur contrôle

Commandes intelligentes pour surveiller et modifier les paramètres

Des conceptions économes en énergie pour réduire les coûts

Options personnalisées pour différentes poudres

Suivez des règles strictes pour fabriquer des médicaments

À propos 80% des nouvelles usines de médicaments utilisent la fabrication continue. Ces usines ont besoin de mélangeurs capables de mélanger des poudres et des liquides à tout moment.. Les mélangeurs personnalisés et complets aident les entreprises à effectuer des tâches spéciales.

Utilisation industrielle

Les mélangeurs pharmaceutiques sont importants pour la fabrication de médicaments, vaccins, et la recherche.

À propos 65% des nouveaux médicaments doivent être soigneusement mélangés.

L'industrie connaît une croissance rapide, avec un 7.8% TCAC, des mélangeurs plus avancés sont donc nécessaires.

Les mélangeurs à entrée supérieure et à montage fixe aident les usines à travailler rapidement et de manière stable.

Les usines utilisent ces machines pour mélanger les poudres, granulés, et liquides. Les systèmes de mixage complets permettent de garantir que tout est bien fait et respecte les règles.. Économiser de l'énergie et utiliser des mélangeurs complets sont importants pour les nouvelles usines de médicaments.

Table de comparaison

Choisir le meilleur mélangeur industriel n'est pas toujours facile. Il y a beaucoup de choses à penser. Chaque mélangeur a ses propres atouts. Certains mélangeurs fonctionnent mieux pour certaines tâches que d'autres. Le le tableau ci-dessous montre en quoi les meilleurs mélangeurs industriels sont différents. Il répertorie leurs principales caractéristiques, ce qu'ils font de mieux, et quand les utiliser.

Machine / Marque | Caractéristiques clés & Paramètres | Scénarios les mieux adaptés | Avantages | Limites |

|---|---|---|---|---|

Guan Yu Mélangeur émulsifiant sous vide | Émulsification sous vide, personnalisable, acier inoxydable, commandes avancées | Produits de beauté, médicaments, nourriture, nouvelle énergie | Résultats cohérents, fort soutien, technologie de pointe | Nécessite une formation d’opérateur |

Mélangeur PerMix V | Chambre en forme de V, mélange de vide, contrôle de la température, différentes tailles | Médicaments, nourriture, produits chimiques, poudres | Efficace, flexible, rentable | A besoin d'espace, nettoyage fréquent |

Mélangeur Ross | Cisaillement élevé, fonctionnement sous vide, lames personnalisées, contrôle de la température | Produits chimiques, nourriture, plastiques, produits de beauté | Fiable, solutions personnalisées, Nettoyage facile | Coût initial plus élevé |

Mélangeur IKA | Commandes intelligentes, programmable, contrôle de la chaleur, du laboratoire à l'échelle industrielle | Médicaments, produits chimiques, biotechnologie, nourriture | Polyvalent, automation, suivi des données | Mises à niveau logicielles nécessaires |

Mélangeurs industriels INDCO | Acier inoxydable, vitesse variable, ingénierie personnalisée, options portables | Peintures, nourriture, produits chimiques, traitement de l'eau | Livraison rapide, support réactif | Assemblage sur place requis |

Mélangeur par lots de Changzhou | Construction robuste, capacité flexible, convivial, lames efficaces | Produits chimiques, nourriture, médicaments, revêtements | Durable, facile à utiliser, bon rapport qualité prix | Plus grande empreinte |

Le fonctionnement d'un mixeur dépend de la vitesse à laquelle le la turbine tourne et combien de temps elle se mélange. Les scientifiques utilisent l'apprentissage automatique, comme Random Forest, pour étudier ça. Changer la vitesse et le temps peut améliorer le mélange, spécialement pour les poudres collantes. Les mélangeurs dotés de commandes intelligentes aident les travailleurs à obtenir le meilleur mélange pour les poudres et les liquides.

Les mélangeurs industriels sont utilisés dans de nombreux types d’entreprises. Les mélangeurs à double palette sont les meilleurs pour le mélange de poudre collante. Ils ont besoin de la bonne vitesse et du bon temps pour bien travailler. Mélangeurs à cisaillement élevé, comme Ross et Silverson, peut mélanger les choses beaucoup plus rapidement. Ils peuvent réduire le temps de mélange de presque 90%. Les mélangeurs par lots sont parfaits pour les gros travaux, comme le traitement de l'eau et l'exploitation minière. Des entreprises comme INDCO et PerMix peuvent fabriquer des mélangeurs adaptés à des besoins particuliers.

Les mélangeurs industriels aident à éviter les erreurs et à améliorer les produits. Lors du choix d'un mixeur, les entreprises devraient réfléchir au type de poudre, combien ils doivent mélanger, et s'ils veulent de l'automatisation. Chaque mélangeur de ce tableau résout différents problèmes de mélange. Cela aide les acheteurs à trouver la meilleure machine pour leur travail.

Les meilleurs malaxeurs industriels en 2025 donner d'excellents résultats. Ils utilisent les nouvelles technologies et offrent une aide précieuse aux utilisateurs. Chaque mélangeur est connu pour être bon, fiable, et capable d'effectuer de nombreux travaux. Lors du choix d'un mélangeur, les acheteurs devraient:

Choisissez un système de mélange adapté au travail, comme mélanger ou dissoudre.

Pensez à combien vous devez gagner maintenant et plus tard.

Choisissez des machines avec des surfaces fermées pour garder les produits sûrs et propres.

Vérifiez la qualité du mélange en recherchant et en utilisant les données, comme vérifier si les choses sont mélangées uniformément ou la taille des morceaux.

N’utilisez pas de machines trop difficiles à utiliser au début. Commencez par des systèmes de mélange simples et flexibles qui fonctionnent bien.

Choisir le bon mélangeur permet de fabriquer de bons produits, fait gagner du temps, et laisse l'usine grandir.

FAQ

Quelles industries utilisent des malaxeurs industriels?

Les malaxeurs industriels sont utilisés dans de nombreux domaines. Entreprises qui fabriquent des cosmétiques, médecine, nourriture, produits chimiques, et de l'eau propre en a besoin. Chaque domaine nécessite un mélange spécial pour ses propres produits.

Comment un mélangeur émulsifiant sous vide améliore-t-il la qualité du produit?

UN Mélangeur émulsifiant sous vide enlève l'air pendant le mélange. Cela rend les produits lisses et uniformes. Il arrête également les bulles et garde les choses propres. De nombreux fabricants l'utilisent pour les crèmes, ondage, et sauces.

Que doivent prendre en compte les acheteurs lors du choix d'un malaxeur?

Les acheteurs devraient réfléchir à la quantité de mélange que la machine peut mélanger. Ils doivent vérifier si cela fonctionne avec leurs matériaux. L'automatisation et l'aide après l'achat sont également importantes. La machine doit répondre aux besoins de l'entreprise. Les choix personnalisés et les documents de sécurité sont également importants.

À quelle fréquence les entreprises doivent-elles entretenir leurs malaxeurs?

Les entreprises devraient souvent prendre soin de leurs machines. Les experts disent de les vérifier et de les nettoyer après chaque utilisation. Des contrôles réguliers et le remplacement des anciennes pièces évitent les problèmes.

Les malaxeurs peuvent-ils être personnalisés pour des processus uniques?

Oui, de nombreuses entreprises vous permettent de changer les machines. Les ingénieurs peuvent les agrandir ou les réduire. Ils peuvent changer les commandes et les pales de mélange. Machines personnalisées aider les entreprises à réaliser des tâches spéciales.

Jeu QQ22? Je n'en ai jamais entendu parler, mais je suis toujours ouvert à de nouvelles expériences de jeu. Je croise les doigts, c'est une bonne chose! Je vais plonger dans jeu qq22 tout de suite!

L'application pldt777 offre une expérience de jeu immersive avec son interface conviviale et sa large gamme de jeux, rendre les loisirs vraiment agréables. Je recommande fortement de vérifier pldt777app

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est ton article qui me donne plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

Entendu parler de Meritking 1628? Cela semble être une option populaire! Faites vos recherches et voyez si c'est votre tasse de thé. Explorez davantage ici méritant 1628

Peut-être que tu voulais dire « Nesine »? Erreur courante. Mais bon, ça vaut quand même la peine de consulter le site: et debout.

Je viens de recevoir la dernière mise à jour d'Okbet et c'est encore mieux! De nouvelles fonctionnalités rendent les paris encore plus amusants. Continuez votre bon travail! Vérifier les mises à jourmise à jour okbet.