Vitesse de remplissage maximale | remplir 200 ml, 2000~ 3000 PC / Hour, La vitesse sera différente lorsque la forme de la bouteille et la taille du cou et le matériau de remplissage formant et autres propriétés physiques |

Taille de diamètre de bouteille applicable | 30-300(Mm) |

Taille de hauteur de bouteille applicable | 30-350(Mm) |

Dose de remplissage | 200~ 2000 ml (personnalisable) |

Précision de remplissage | ± 0,5% - ± 0,8% |

Tension | AC220V, monophasé, 50/60HZ |

Pouvoir | 4.5 KW |

Pression de travail | 0.55-0.65 Mpa |

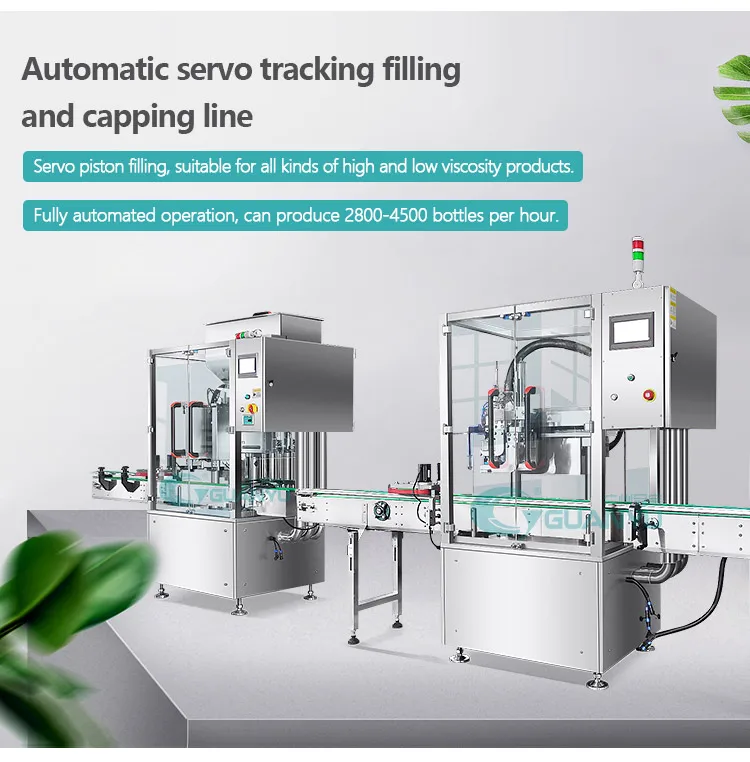

Méthode de remplissage | Suivi du piston servo |

Contrôle du programme | Interface de l'homme-machine PLC + écran tactile |

Vitesse de plafonnement | 2000-3000 bouteilles / heure |

Couverture inférieure | Plaque manuelle ou vibrante |

Caractéristiques principales (Machine de remplissage):

1、Cette machine est équipée d'un système de stockage de paramètres. Lorsque vous modifiez la taille de la bouteille ou le volume de remplissage, Appuyez simplement sur une touche sur l'écran tactile pour régler.

2、Le cylindre entraîne la plongée de la buse de remplissage et correspondait à la vitesse de remplissage variable qui peut réduire le moussage lors du remplissage, ce qui peut éviter de polluer les bouteilles.

3、Sur l'interface man-machine, Le volume de remplissage de différentes têtes de remplissage peut être affiné individuellement.

4、Le capteur de niveau de matériau est utilisé pour vérifier la position de niveau sous le fonctionnement normal de la machine,Plus avec un périphérique de vérification et d'alarme de niveau élevé et de bas niveau. Le dispositif d'inspection de niveau est en PTFE, avec une fonction anti-corrosion parfaite.

5、Le corps de la machine est fabriqué par 304 acier inoxydable, facile à nettoyer, La machine est pleinement conforme aux exigences GMP.

Caractéristiques principales (Machine de plafonnement):

2.Cette machine est équipée d'un système de stockage de paramètres. Lorsque vous modifiez la taille de la bouteille, Appuyez simplement sur une touche sur l'écran tactile pour l'ajuster.

3.Cette machine adopte le contrôle complet du servo, y compris la hauteur de la tête de plafonnement, la vitesse de traduction de la griffe de plafonnement, et le contrôle du couple de plafonnement.

4.Selon différents matériaux d'emballage, Vous pouvez choisir d'utiliser différentes têtes de plafonnement.

5.Qui adoptent la tête de plafonnement de la torsion d'identité, Le dispositif de plafonnement n'a pas pu blesser le capuchon .

6.Qui peut être égal à la ligne d'emballage.

Commentaires

Il n'y a pas encore de critiques.