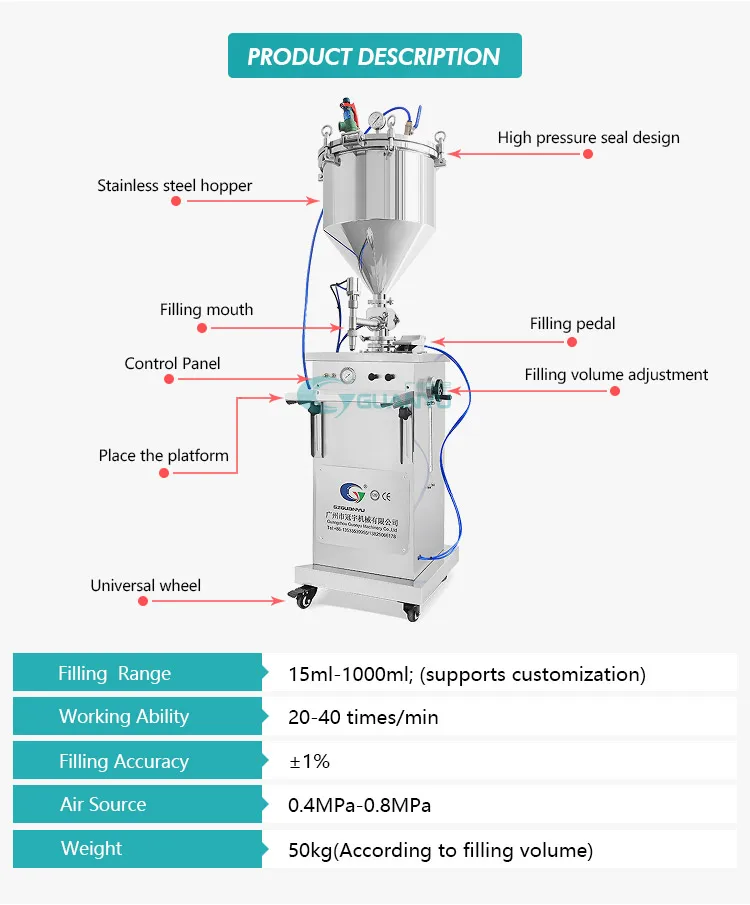

Machine de remplissage de sachet vertical de remplissage vertical de sachet vertical en acier inoxydable semi-automatique

Configuration du produit

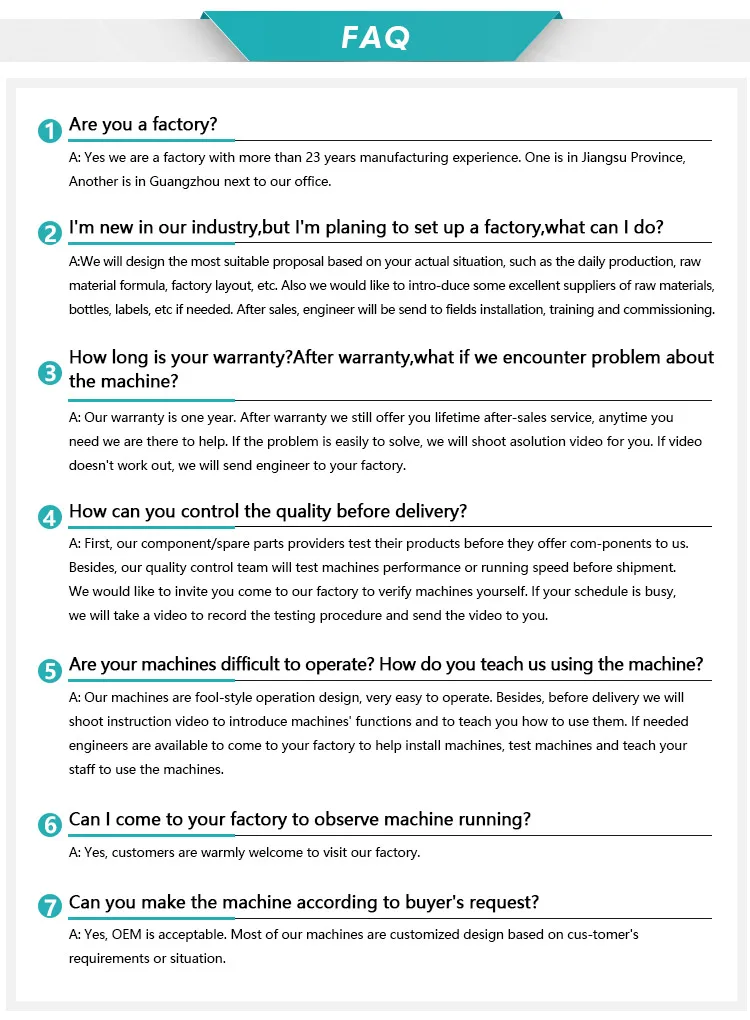

Modèle | Volume de remplissage | Précision de remplissage | Consommation d'air | Productivité |

LGJ-W-15 | 5-150ml | 0.2% | 23L/min | 20-50bot / i |

LGJ-W-25 | 10-250ml | 0.2% | 30L/min | 20-50bot / i |

LGJ-W-17 | 30-500ml | 0.2% | 44L/min | 20-50bot / i |

LGJ-W-18 | 60-1000ml | 0.2% | 87L/min | 20-50bot / i |

LGJ-W-19 | 250-2500ml | 0.2% | 160L/min | 20-50bot / i |

LGJ-W-20 | 500-5000ml | 0.2% | 300L/min | 20-50bot / i |

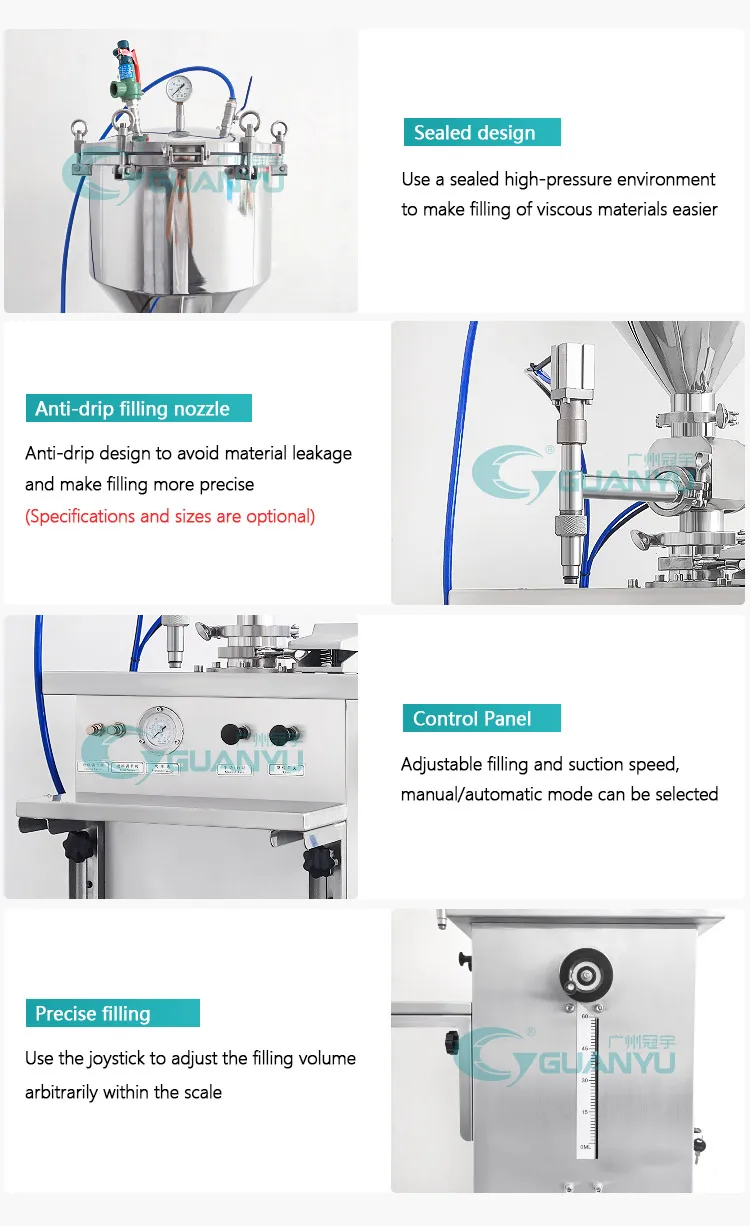

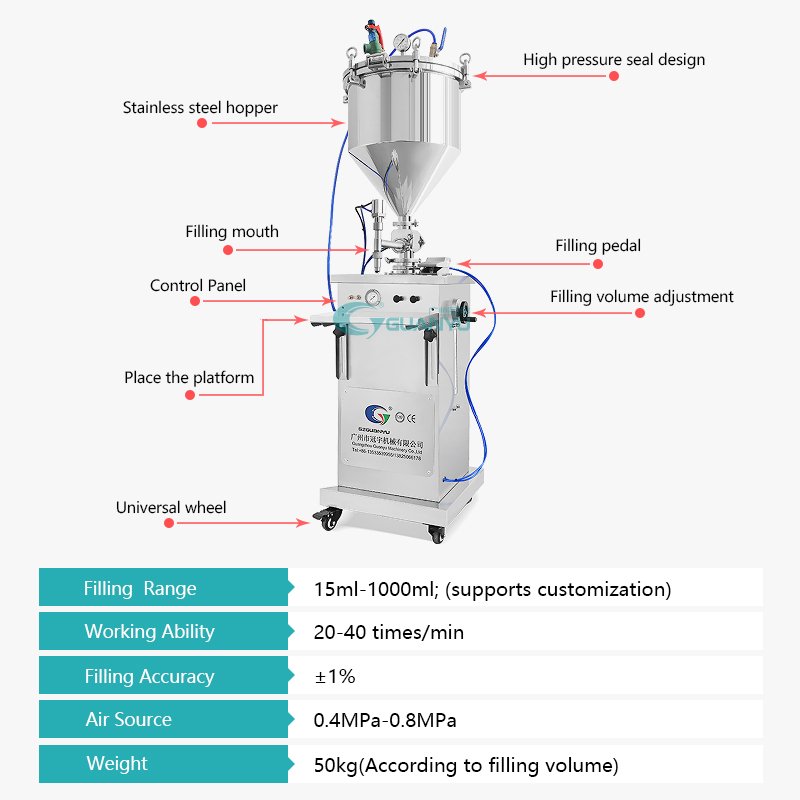

1.Application: Liquide & Offre de crème Garantie et maintenance à vie d'un an. Il convient à la garniture liquide, Nouveau design horizontal, commodité légère, Facile à utiliser 2. Cette machine adopte des pièces de machine importées Pistion et cylindre en acier inoxydable et en polytétraflutoéthylène excellents composants importés qualifiés et conception mecanique parfaite. ,La machine se remplit en continu 5.Automatiquement avec une vitesse définie. Lorsque la machine est à condition automatique ,L'opérateur marche sur la plaque de pied pour réaliser le remplissage si vous marchez sur le pied de pied tout le temps., Cylindre et partie à trois voies adopter la connexion à la manche qui est facile à supprimer ,ça ne fait pas,T a besoin de tous les outils spéciaux afin qu'il soit facile de nettoyer le système de remplissage anti-fuite 6. En remplissant ,le cylindre se déplace de haut en bas et de conduire un anneau d'extrémité ,Quand le cylindre est vers le bas ,La fin est vers le bas, alors la valve est ouverte et commence à remplir le matériau ;Lorsque le cylindre est un anneau d'extrémité vers le haut, la valve est proche et s'arrête pour remplir la motif et éviter les fuites et le dessin de fil

À propos de nous

Certifications

FAQ

Commentaires

Il n'y a pas encore de critiques.