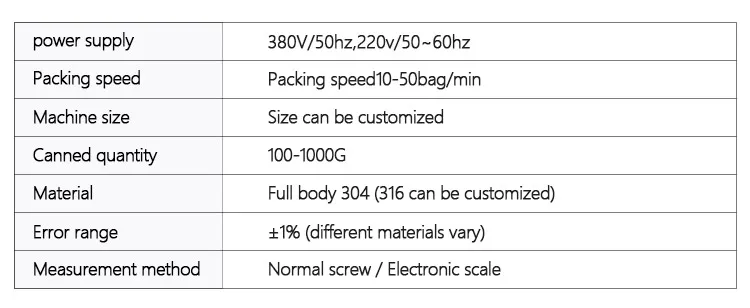

Vitesse de remplissage maximale | remplir 200 ml, 2000~ 3000 PC / Hour, La vitesse sera différente lorsque la forme de la bouteille et la taille du cou et le matériau de remplissage formant et autres propriétés physiques |

Taille de diamètre de bouteille applicable | 30-300(Mm) |

Taille de hauteur de bouteille applicable | 30-350(Mm) |

Dose de remplissage | 500~ 5100 ml (personnalisable) |

Précision de remplissage | ± 1% |

Tension | AC220V, 50/60HZ |

Pouvoir | 5.0KW |

Pression de travail | 0.4 ~ 0,6pa |

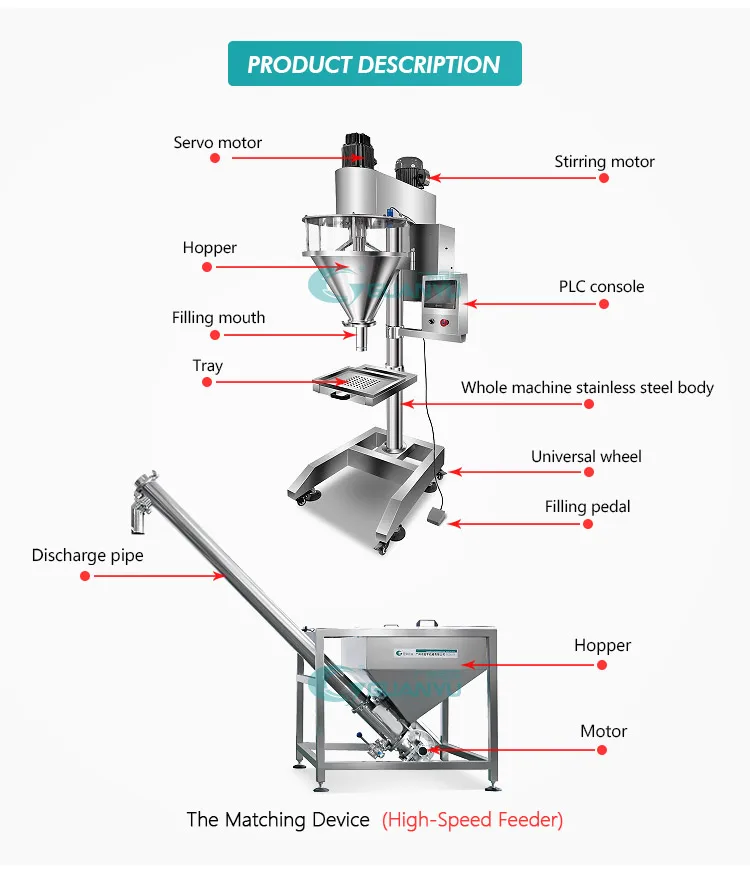

Contrôle du programme | Interface de l'homme-machine PLC + écran tactile |

Vitesse de plafonnement | 2000-3000 bouteilles / heure |

Couverture inférieure | Plaque manuelle ou vibrante |

Direction de la machine | De gauche à droite |

Caractéristiques principales (Machine de remplissage):

1、L'équipement a une forte compatibilité, et peut rapidement régler et remplacer les bouteilles de différentes formes et spécifications sans remplacer les pièces, qui peut répondre aux exigences de production de plusieurs variétés et spécifications.

3、L'utilisation de composants électriques de marque Famouse Internatioal, performance et stabilité.4、L'utilisateur peut ajuster la plage de remplissage, Les matériaux ne suffisent pas à Hopper, L'ordinateur donnera au signal de pompe d'alimentation Toaddmaterial par capteur de niveau. Lorsque le matériau est plein, la pompe s'arrêtera automatiquement.、Le corps de la machine est fabriqué par 304 acier inoxydable, facile à nettoyer, La machine est pleinement conforme aux exigences GMP.6、Pompe péristaltique ou système de remplissage de pompe à piston, mesurer la précision, manipulation pratique.

Caractéristiques principales (Machine de plafonnement):

2.Qui peut être égal à la ligne d'emballage.3. qui s'appliquait à un plafond différent dans différents matériaux et différentes spécifications.4.Quon adopter la tête de coiffage de torsion d'identité, Le dispositif de plafonnement n'a pas pu blesser le capuchon. ,il est facile de réguler la pression. ,Bouchon de type vis , Cap, capuchon de compression, etc…

Commentaires

Il n'y a pas encore de critiques.