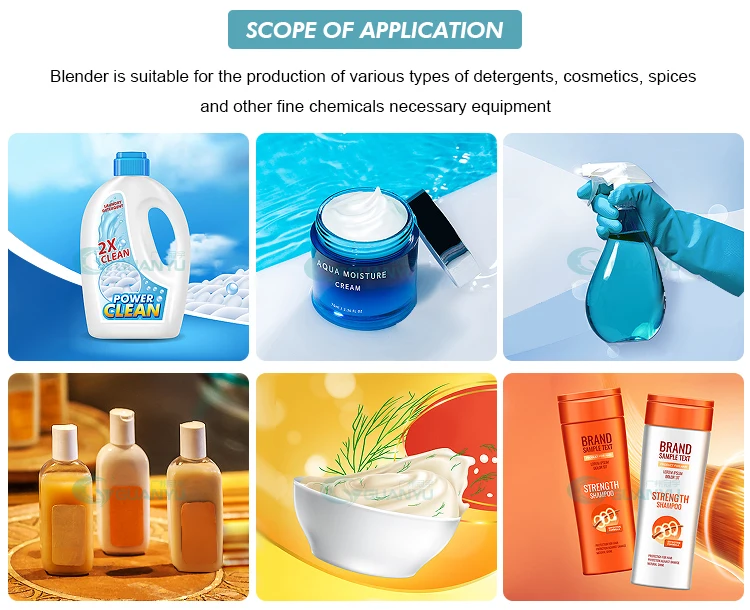

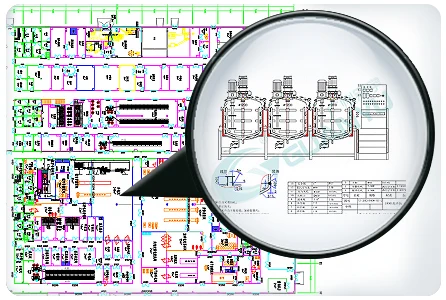

Mélangeur de détergent liquide personnalisé 5000L, usine de production de détergent, réservoir de mélange de savon liquide chimique, Machine de fabrication

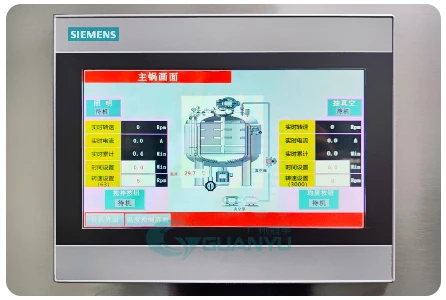

Caractéristiques:1. Le matériau de la pièce en contact est l'acier inoxydable SUS316L, l'intérieur et l'extérieur de l'équipement sont polis miroir et répondent à la norme GMP.2. Tous les pipelines et paramètres sont contrôlés automatiquement. Et les appareils électriques importés d'un pays étranger,comme Siemens ,Schneider et ainsi de suite.3. Le réservoir émulsifiant est équipé d'un système de nettoyage CIP,cela rend le nettoyage facile et efficace.4. Le réservoir émulsifiant adopte un système d'agitation tertiaire, et pendant l'émulsification ,l'ensemble du traitement se fait sous vide, de sorte qu'il peut non seulement éliminer les écumes créées lors du traitement d'émulsification ,mais peut également éviter la pollution inutile.5. L'homogénéisateur adopte la technologie la plus avancée,il peut obtenir un effet émulsifiant idéal. La vitesse d'émulsification élevée est de 0 à 3600 tr/min, et la vitesse de faible mélange est de 0 à 63 tr/min.

Modèle | Volume(L) | Pouvoir de mélange(kW) | Vitesse de rotation du mélange(tr/min) | Pouvoir homogénéisant(kW) | Vitesse de rotation d'homogénéisation(tr/min) | Méthode de chauffage |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Chauffage vapeur ou chauffage électrique |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

Palette de mélange

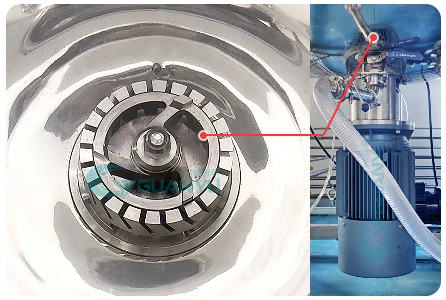

Homogénéisateur

Régulation de vitesse de conversion de fréquence 0-3200r/min, tête de cisaillement homogène matériaux de cisaillement à grande vitesse, afin que les matériaux soient complètement brisés et mélangés!

◭Le mélange de grattage mural polyvalent adopte le convertisseur de fréquence pour le réglage de la vitesse , de sorte que les produits de haute qualité de processus différents en fonction des exigences du client.

Pompes à vide

Échangeur de chaleur à plaques et cadres

Palan à matériaux

Vanne pneumatique

Console

Service

1..Qui sommes-nous?

Commentaires

Il n'y a pas encore de critiques.