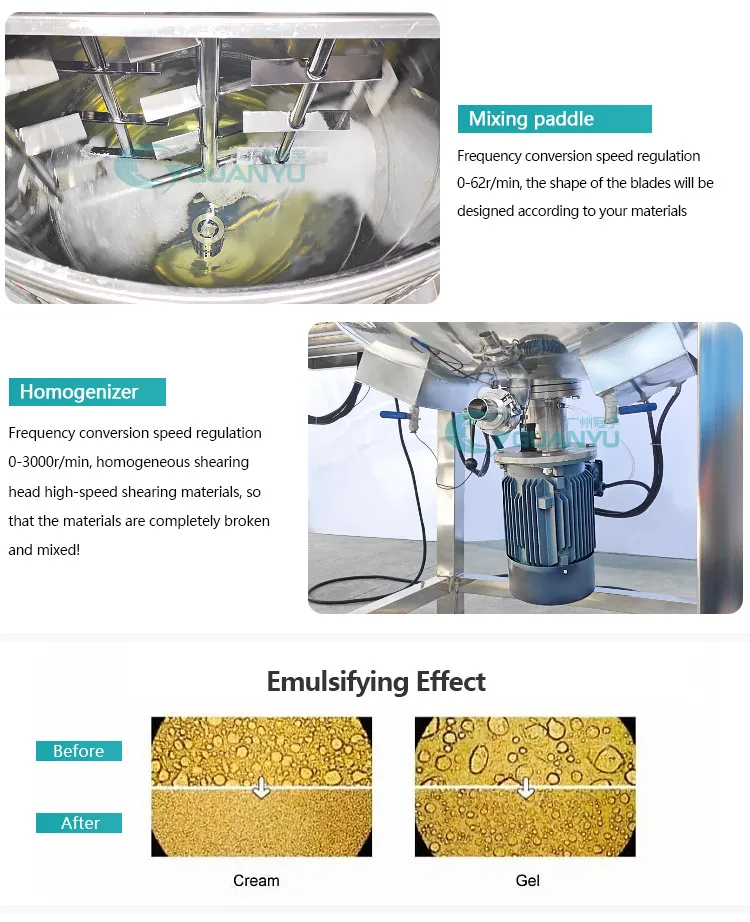

500L Jacket Heating Mixing Tank for Serums Homogenizer Mixer Liquid soap making machine Combination mixing machine

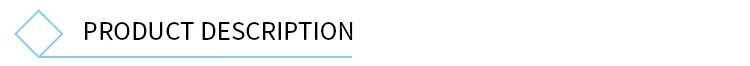

Vitesse de mélange | variable speed 0~63rpm |

Vitesse d'homogénéisation | variable speed 0~3500rpm |

Motor brand | SIEMENS/ABB |

Converter | SIEMENS/Mitsubishi/Delta |

Temperature controller | Omron/CHNT/Delixi/etc |

Type de contrôle | PLC/Electric button manual |

Matériel | Acier inoxydable 316/304/304 |

Méthode de chauffage | Electric heating/Steam heating |

Cooling method | Tap water/Chiller water |

Capacité | 50~5000L(Custom designed) |

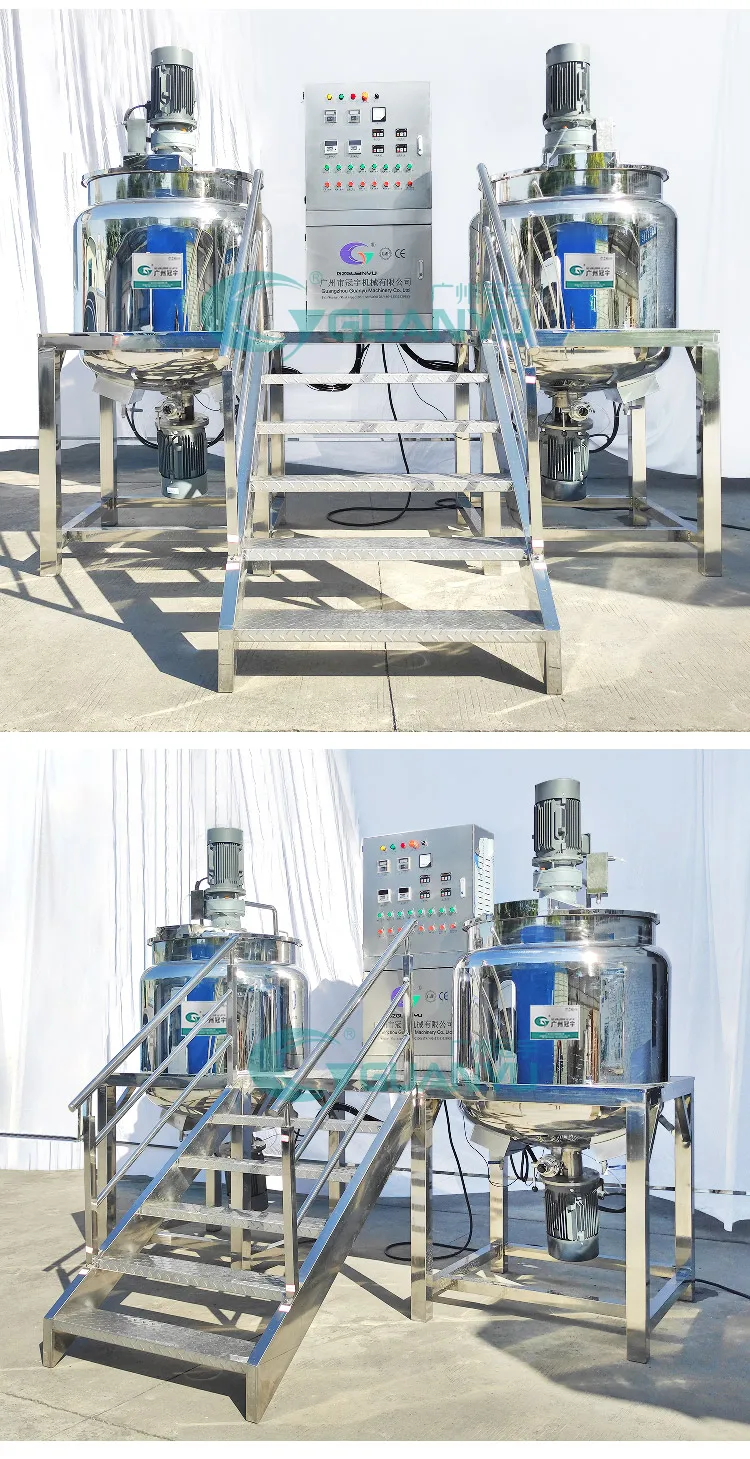

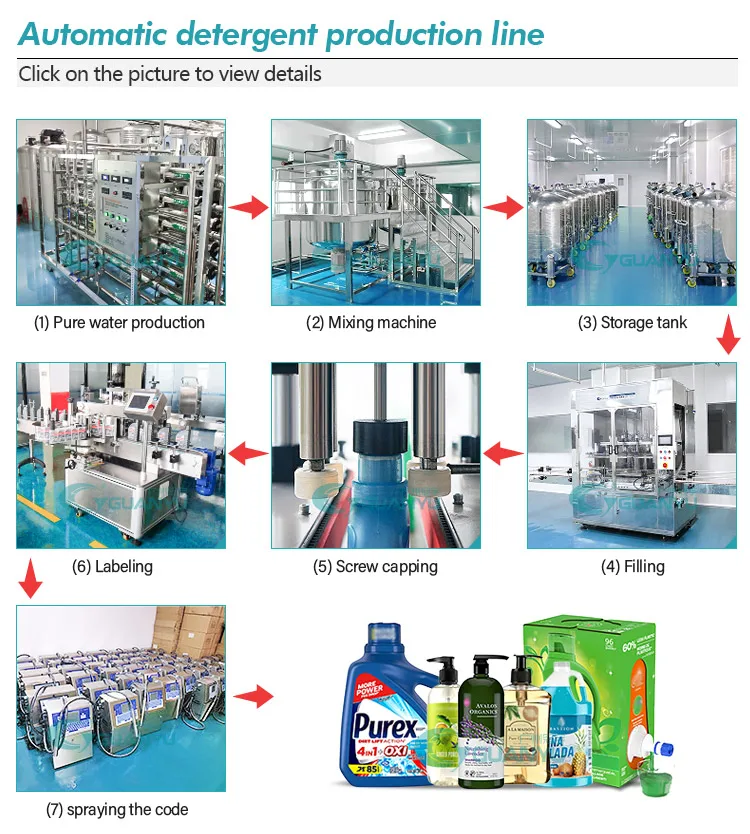

Application | Cosmetics cream /lotion / gel / shampooing / liquid soap /detergent / Mayonnaise / ketchup /etc |

Cover type | Opened/Un-opened |

Discharge type | Bottom discharge |

◭Le mélange de grattage mural polyvalent adopte le convertisseur de fréquence pour le réglage de la vitesse , so that high quality products ofdifferent processes according to customer requirements.

◭ L'homogénéisateur diversifié à grande vitesse peut mélanger puissamment les matières premières solides et liquides et peut rapidement dissoudre des matériaux de plusieurs indissolubles tels que des AES , AESA , LSA , etc.. pendant le processus de production de détergent liquide afin d'économiser la consommation d'énergie et de raccourcir la période de production.

◭ Le corps du pot est soudé par une plaque en acier inoxydable importée à trois couches. Le corps du réservoir et les tuyaux adoptent un polissage mittor , qui est entièrement conforme aux exigences GMP.

◭Selon l'exigence du client , le réservoir peut chauffer et refroidir les matériaux. Le mode de chauffage comprenant le chauffage à vapeur et le chauffage électrique. Facile à décharger , décharge directe par le bas ou par pompe de transfert.

Our service1.Warranty time:one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.2.Commissioning services:the product’s installation and commissioning at the demand side, our engineers will not leave there untill get your agreement.3.Training services: our engineers will train your staff to operate it during the period of installation and commissioning, andthey will not leave there until your staff can operate it properly and normally.4.Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.5.Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discountprice.6.Certificate services:we can provide related certificates to customers freely according to the request of customers.7.Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.8.The file: the Manual Specification, report of the material which used to the equipment and others documents related to the GMP authentication information will be provided by us.

RFQ

1 .Q Do you accept a special order? UN: Oui ,we do ; We can manufacture all kinds of chemical equipments according to your technical drawings; 2.Q: Can you give us a quotation right now? UN: Please give us the detail of the technical so we will design and quotate for you as soon as possible;3.Q: Do you have one in stock? UN:Désolé. We don’t. All products are manufactured according to customer’s requirement;4.Q: Can you make a design for us? UN:Yes We can What we supply is not only product but also solution and design;5.Q:Can your engineer come to our place for installation guides? UN:Oui, we can we will provide a video and document for installation;If you still have problems we will send our engineer oversea for installation guide; For your inquiries, pls kindly let us know: 1. What is your products? Crème,toothpast, moisturizer,night cream, vanishing cream,suncream etc. 2. What is the capacity do you want for this vacuum emulsifying machine? 100L,200L300L,500L,1000L, etc.. 3. Required heating method: electric heating or steam heating? 4. Required voltage and frequency of power supply? eg:380V 50Hz 3phase? 5. 5. Requirement of Certificate (CE, UL, CSA, or no need)

Commentaires

Il n'y a pas encore de critiques.