Réservoir de mélange industriel, homogénéisateur de crème cosmétique, Machine d'émulsification sous vide, Machine de fabrication de lotion pour le visage

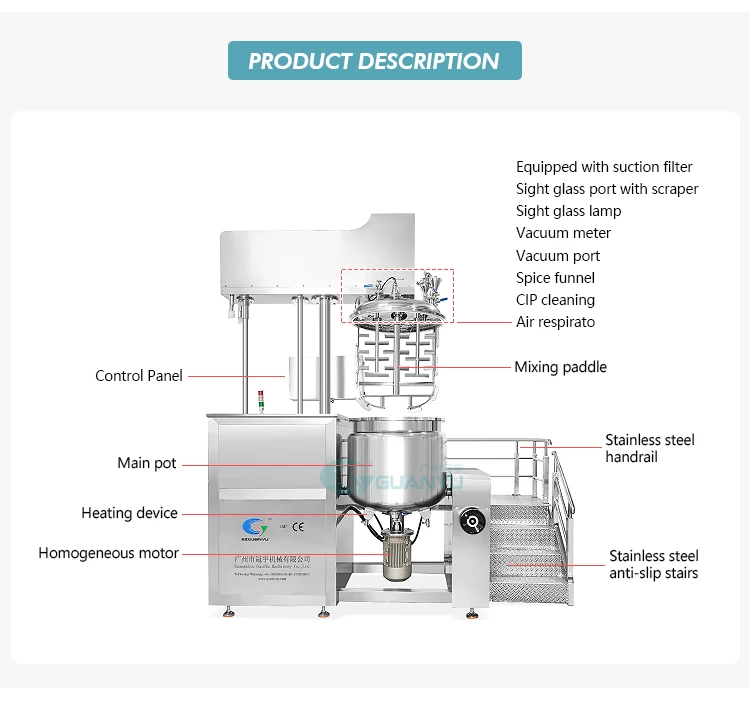

Description des produits

Modèle | Capacité efficace | Émulsifier | Agitateur | Dimension extérieure | Le méritrate(KW) | |||

KW | tr/min | KW | tr/min | Longueur * Largeur * Hauteur (mm) | Max h | |||

20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800*1600*1850 | 2700 | 5 |

50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700*2000*2015 | 2700 | 7 |

100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920*2120*2200 | 3000 | 10 |

150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110*2120*2200 | 3100 | 11 |

200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150*2200*2200 | 3100 | 12 |

350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650*2650*2550 | 3600 | 17 |

500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970*2800*2700 | 3950 | 19 |

750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780*3200*3050 | 4380 | 24 |

1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900*3400*3150 | 4550 | 29 |

1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000*4100*3750 | 5650 | 42 |

2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850*4300*3600 | / | 46 |

Introduction1. La machine a un triple mélangeur, couvercle de levage hydraulique, Blender d'homogénéité à grande vitesse (La vitesse est de 0-3500r / min, Régulation de la vitesse de fréquence) et mélangeur de grattoir à basse vitesse (La vitesse est de 0-40r / min, Régulation de la vitesse de fréquence). Le mélange d'émulsification du vortex rapide est utilisé dans la partie homogénéisateur, qui peut gratter à basse vitesse et se mélanger et se blottir automatiquement jusqu'au fond et au mur de la chaudière. La machine dessine du matériau de poudre par voie sous vide afin d'empêcher la poudre de voler. L'ensemble de la procédure de travail est exploité dans l'état du vide afin d'empêcher que le matériau entre la bulle après un mélange à grande vitesse et d'atteindre la demande d'assainissement et d'asepsis. Le système de nettoyage CIP est équipé dans ce système. La partie de contact du navire et du matériel est fabriquée à partir de matériaux SUS316L. La finition miroir de la surface intérieure est de 300emsh. Afin d'assurer la stabilisation du contrôle, La pompe à vide est les produits de l'Allemagne Siemens Company, Le bouton est produit par le Japon Fujicompany, Le transducteur est le produit du Japon Matsushita Electric Industries et la partie électro-contrôlée est le produit de Siemens Company. La machine est entièrement faite en fonction de la demande GMP, qui est l'équipement de production de crème le plus avancé et le plus parfait.. La machine est spécialement conçue en adoptant une technologie de pointe de l'outre-mer selon la technologie de production de cosmétiques et de pommade. La machine est composée de chaudière de prétraitement, Chaudière à mélange émulsification sous vide, pompe à vide, Système hydraulique et table de travail.. La machine a un fonctionnement facile, capacité régulière, bonne homogénéité, grande efficacité, structure raisonnable, petit volume et niveau d'automatisation élevé et facilement propre. Usagept-thzrj Vacuum Emulsification Le mélangeur est spécialement conçu en adoptant une technologie de pointe de l'outre-mer en fonction de la technologie de production cosmétique et de pommade. La machine est composée de chaudière de prétraitement, Chaudière à mélange émulsification sous vide,pompe à vide, Système hydraulique et table de travail. Caractéristique Cette unité a des fonctionnalités telles que des opérations simples, performance stable, bonne homogénéisation, Efficacité de production élevée, Nettoyage pratique, structure raisonnable, petit espace de plancher, et une automatisation élevée, etc..

Palette de mélange

La régulation de vitesse à fréquence variable est de 0 à 62 tr/min, afin que différents matériaux puissent être mélangés uniformément. La forme de la palette de mélange sera conçue en fonction de vos matériaux

Homogénéisateur

Régulation de vitesse de conversion de fréquence 0-3200r/min, tête de cisaillement homogène matériaux de cisaillement à grande vitesse, afin que les matériaux soient complètement brisés et mélangés!

Accessoires

Matériel SS316, épaisseur 6 mm,Equipé d'un filtre d'aspiration, robinet de vidange, port de vide, lampe à verre de visée, port de regard avec grattoir, entonnoir à épices, Nettoyage CIP, Respirateur à air

Pot huile-eau

Le réservoir de phase d'eau et le réservoir de phase de huile du système de prétraitement préchauffent et dispersent les matières premières, puis les transférer dans le réservoir principal, et commencer un mélange homogène pour émulsionner les matières

Console

Le boîtier de commande comprend des réglages tels que le cisaillement homogène, mélange de régulation de vitesse de conversion de fréquence,

timing de travail, extraction sous vide, chauffage intercalaire, etc..

timing de travail, extraction sous vide, chauffage intercalaire, etc..

Console

Nous concevrons des dessins selon vos besoins et fournirons des solutions uniques.

Configuration du produit

À propos de nous

Processus de dossier réussi

Certifications

FAQ

Commentaires

Il n'y a pas encore de critiques.