300 L Lotion sous vide shampooing homogénéisateur émulsifiant émulsifiant mélangeur Machine soins de la peau crème cosmétique dentifrice faisant la Machine

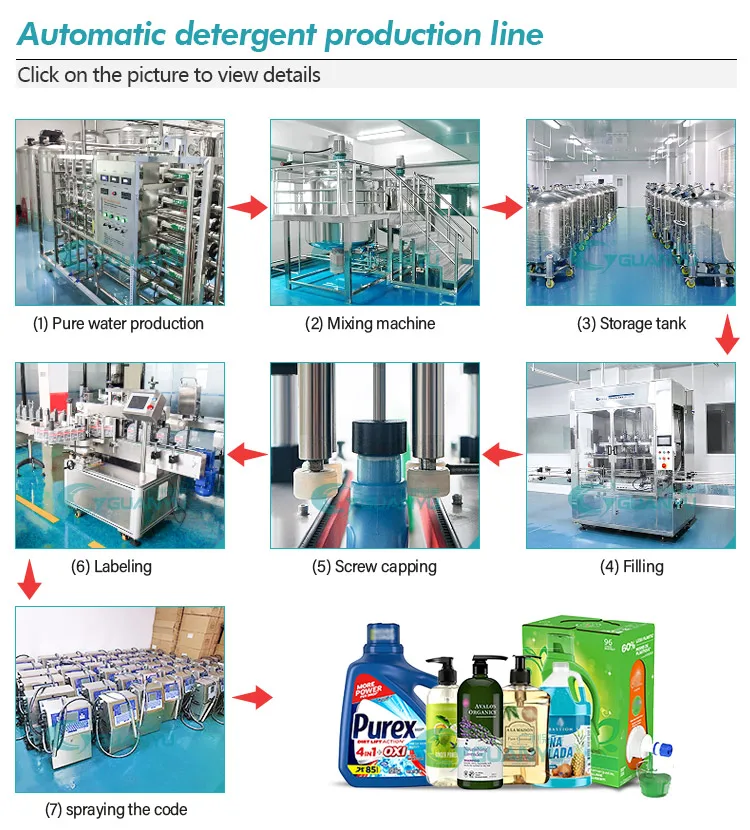

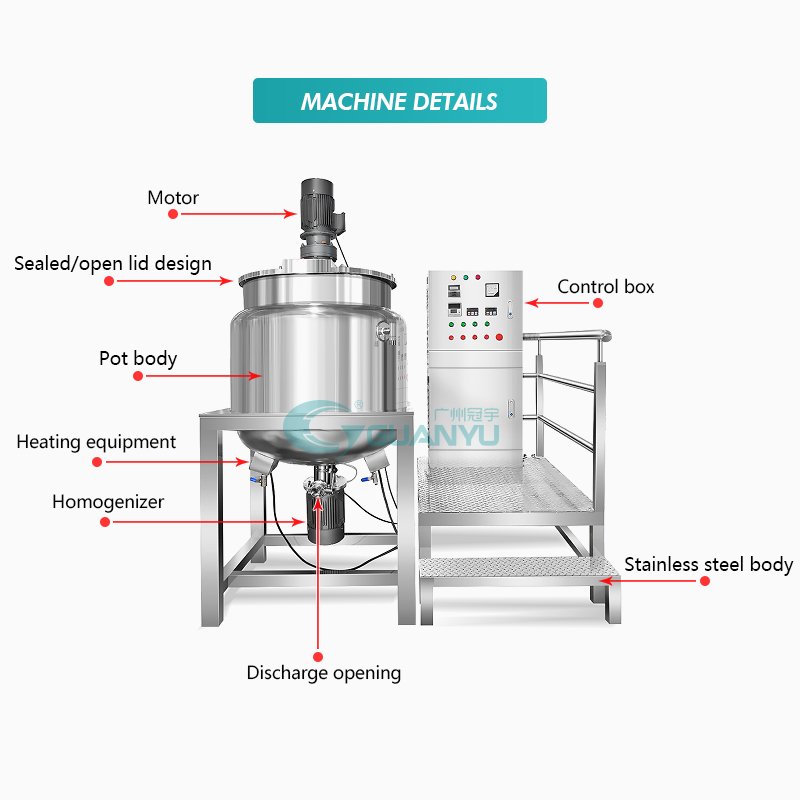

La chaudière à réaction de mélange GYM convient principalement à la préparation de détergents liquides (comme l'essence nettoyante, shampoing et crème de douche, etc.). intégrer le mélange, dispersion, chauffage et refroidissement, etc.. fonctions, la machine à réaction est un appareil idéal pour la préparation de liquides dans diverses usines.

Configuration du produit

Modèle | Efficace | Stirrring power and speed | Puissance et vitesse homogènes | Puissance de chauffage | |||

Capcity | KW | R / min | KW | R / min | Chauffage électrique | Chauffage à la vapeur | |

Gym-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6KW | Conservation de l'énergie de chauffage à vapeur et protection de l'environnement, sélectionné selon le besoin |

Gymnase-100 | 1100 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GYM-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | |

GYM-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

Gym-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18KW | |

GYM-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27KW | |

GYM-1000 | 1000 | 4 | 0-65 | 5.5 | 3600 | 36KW | |

GYM-1500 | 1500 | 4 | 0-65 | 7.5 | 3600 | 45KW | |

GYM-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | recommed steam heating | |

GYM-3000 | 3000 | 7.5 | 0-65 | 11 | 3600 | ||

GYM-5000 | 5000 | 11 | 0-65 | 15 | 3600 |

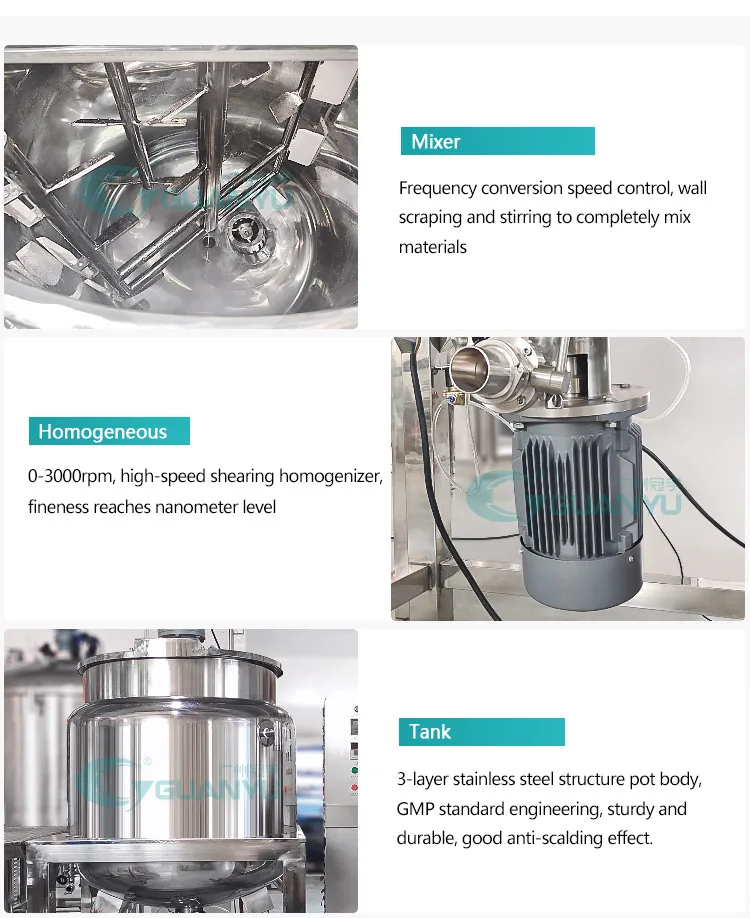

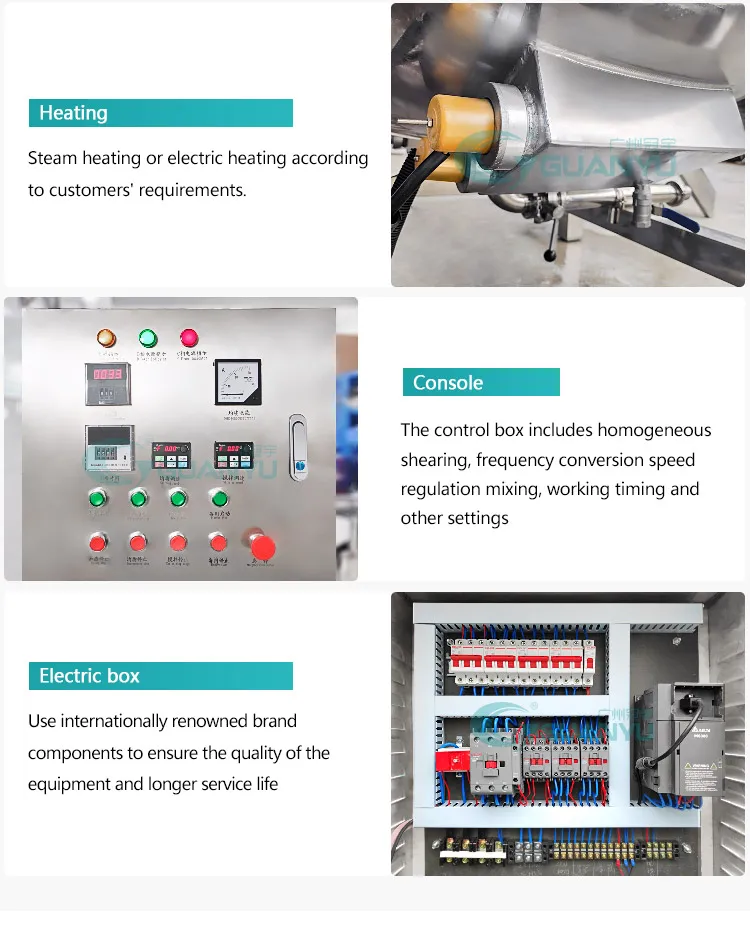

Disperseur à grande vitesse. Mélange et dispersion visqueux. Les matières premières solides et liquides peuvent dissoudre les matériaux qui sont difficiles à dissoudre, comme les AI, AESA LSA pendant la production liquide qui peut économiser la consommation d'énergie et raccourcir la production et raccourcir la période de production., de sorte que les produits de haute qualité de processus différents en fonction des exigences du client. L'homogénéisateur à grande vitesse diversifié peut mélanger puissamment les matières premières solides et liquides et peut rapidement dissoudre des matériaux de nombreux indissolubles tels que des EI, AESA, LSA,etc. pendant la période de production de détergent liquide. Le corps du pot est soudé par une plaque en acier inoxydable à trois couches importée. Le corps du réservoir et les tuyaux adoptent le polissage du miroir, qui est entièrement conforme aux exigences GMP en fonction des exigences du client, Le réservoir peut chauffer et refroidir les matériaux à la manière du chauffage, y compris le chauffage à la vapeur et le chauffage électrique.,décharge directe par le bas ou par pompe de transfert.

Configuration du produit

À propos de nous

Processus de dossier réussi

Certifications

FAQ

Commentaires

Il n'y a pas encore de critiques.