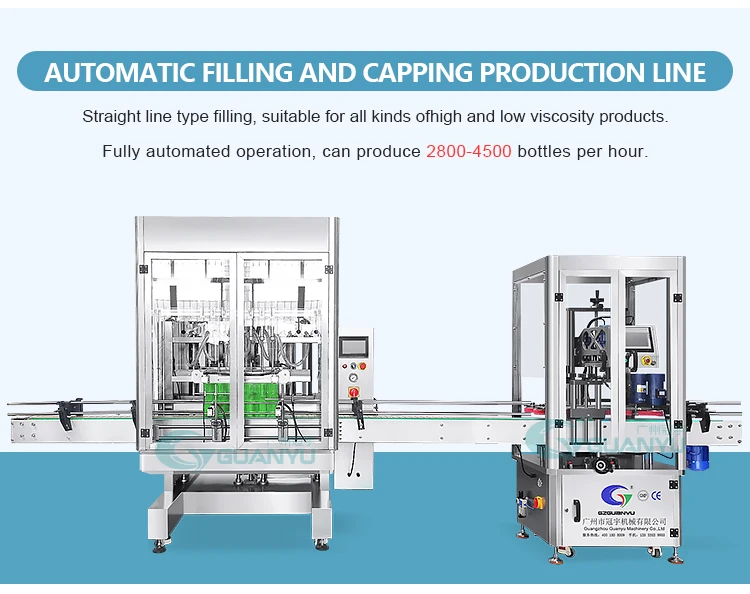

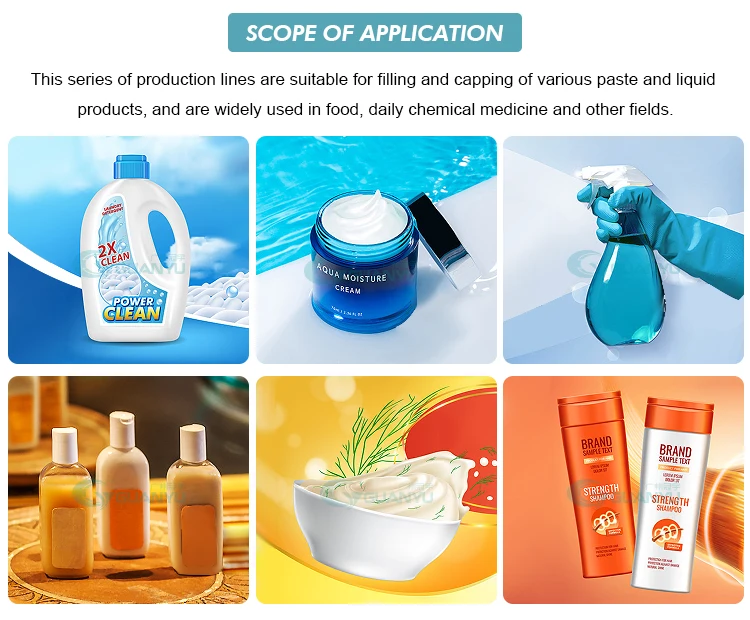

Désinfectant pour les mains Gel Shampooing Savon Liquide Détergent Crème Remplisseur Bouteille Remplissage Capsulage Etiqueteuse Ligne de Production Automatique

Description des produits

Vitesse de remplissage maximale: | remplir 200 ml, 2000~ 3000 PC / Hour, La vitesse sera différente lorsque la forme de la bouteille et la taille du cou et la formation de matériau de remplissage et d'autres propriétés physiques |

Taille de diamètre de bouteille applicable: | 30-300(Mm) |

Taille de hauteur de bouteille applicable: | 30-350(Mm) |

Dose de remplissage: | 100~ 1000 ml (personnalisable) |

Précision de remplissage: | ± 1% |

Tension: | 220V / 380V (personnalisable) |

Pression de travail: | 0.6MPA |

Vitesse de plafonnement: | 2000-3000 bouteilles / heure |

Couverture inférieure: | Plaque manuelle ou vibrante |

Contrôle de l'écran tactile

Le panneau de configuration de l'écran tactile rend plus pratique pour régler le paramètre.,Et les données de travail visuel vous aident à remplir plus précisément le liquide.

Buse de remplissage

La buse de remplissage est avec une conception anti-droping,Assurez-vous que le nettoyage de la production. Chaque buse peut être contrôlée séparément. Nous pouvons également personnaliser 2/6/8 Buzle de remplissage de cette machine.

Capteur léger

L'œil électrique est conçu pour détecter les bouteilles,empêcher de manquer ou de gaspiller des bouteilles. Il ne remplira pas de liquide si aucune bouteille ne passe,Réduire l'erreur de production.

Alimentation automatique

La machine à remplir est équipée d'un capteur de niveau liquide. Lorsque le matériau dans la trémie est inférieur à une certaine position, il sera automatiquement alimenté par le système d'alimentation (Pompe à diaphragme / pompe de rotor / pompe à vis).

Contrôle de l'écran tactile

Panneau de configuration de l'écran tactile, Vous pouvez modifier le temps de plafonnement pour modifier l'étanchéité du plafonnement, avec un bouton d'arrêt d'urgence pour assurer la sécurité de la production.

Tête de plafonnement

Adopter des roues en plastique, Pas de mal à la surface du capuchon lorsque vous vissez le capuchon. La largeur peut être ajustée librement, utable pour de nombreuses formes / tailles différentes de bouchons de bouteille

Convoyeur

Cette machine est équipée d'une courroie de convoyeur automatique, qui peut être utilisé avec des équipements back-end tels que l'étiquetage pour réaliser la production automatique et améliorer efficacement l'efficacité du travail.

Réglage de la hauteur

En ajustant le bouton de hauteur, La hauteur de travail peut être ajustée en fonction de la hauteur de la bouteille. Cela garantit que la machine peut être utilisée pour autant de bouchons de bouteille que

possible.

possible.

Commentaires

Il n'y a pas encore de critiques.