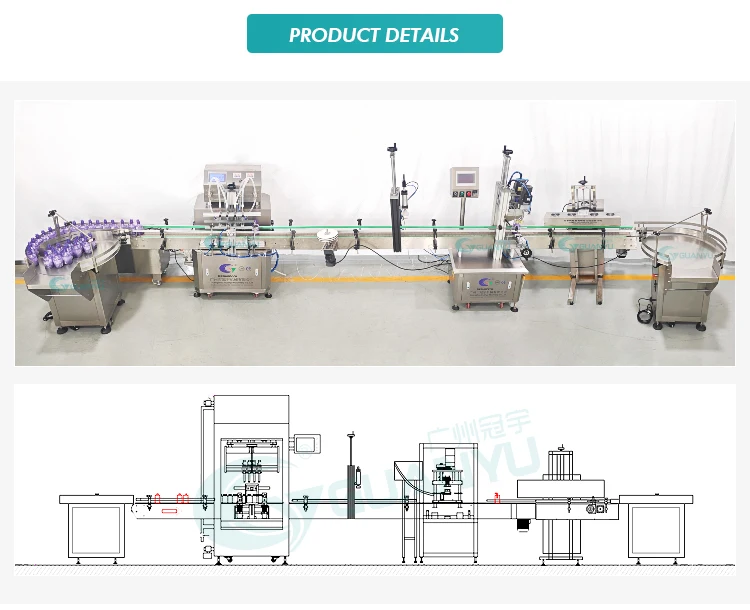

Serve | All equipment of the production line can be customized according to customer requirements |

Max filling speed | filling 200ml, 2000~3000 pcs/hour, speed will be different when bottle shape and neck size and the filling material forming andother physical property |

Applicable bottle diameter size | 30-300(mm) |

Applicable bottle height size | 30-400(mm) |

Filling dose | 500 ~ 5000 ml (Customizable) |

Précision de remplissage | ±1% |

Tension | 110V~680V, peut être personnalisé |

Put the bottle | Bottle unscrambler automatic bottle release |

Working pressure | 0.4 – 0.6MPa |

Program control | PLC+touch screen man-machine interface |

Capping speed | 2000-3000 bottles/hour |

Lower cover way | Manual or vibrating plate |

Sealed | Aluminium foil seal can be added if required |

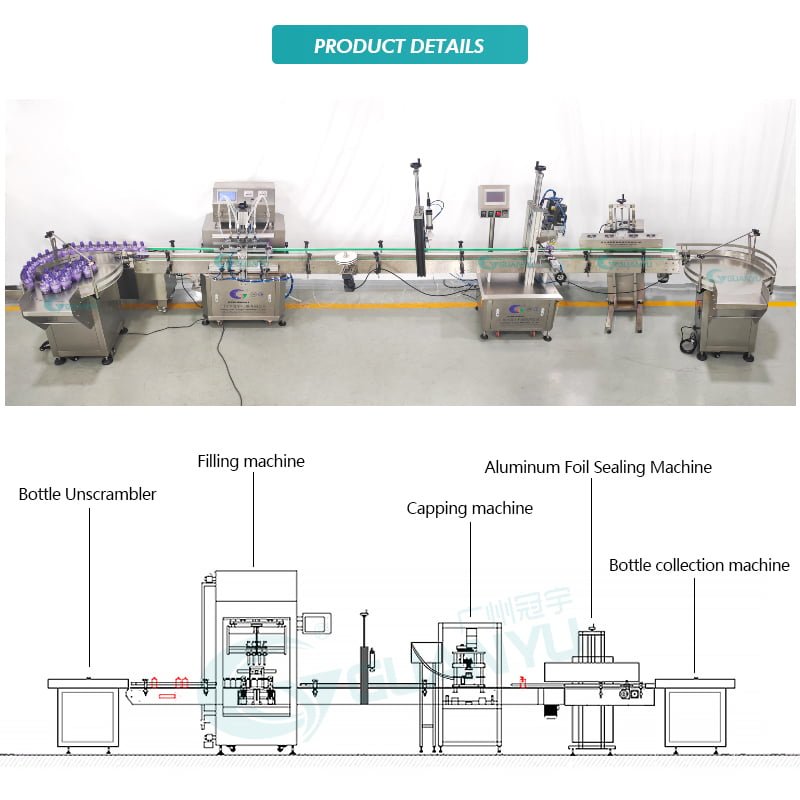

Main Features(Bottle unscrambler):

1、Suitable for automatic bottle separation and automatic transfer of round and square bottles, compatible with plastic and glassbottles,

4、The diameter of the applicable bottle can be adjusted freely, and it is compatible with peeling bottles and plastic bottles. The bottle conveying speed is 30~200 bottles/min. The speed can be adjusted steplessly, which is convenient for production arrangement.

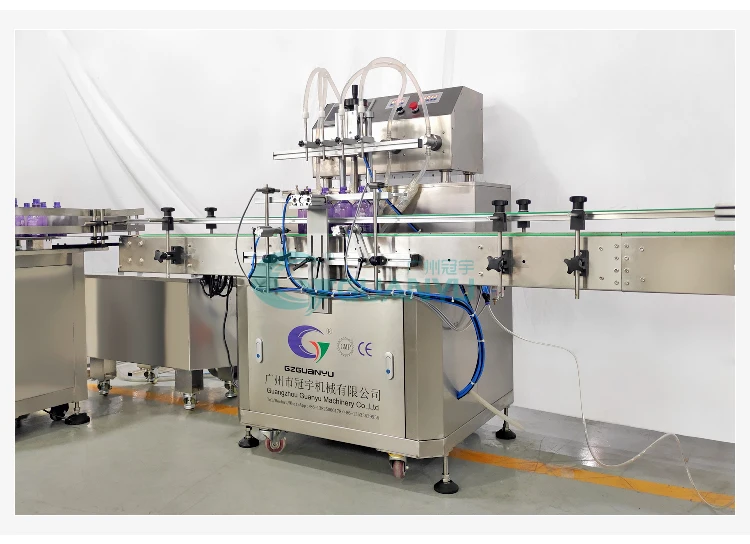

Main Features(Filling machine):

1、The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specificationswithout replacing parts, which can meet the production requirements of multiple varieties and specifications

2、PLC control ,touch bottle operatation ,simple and convenient operation.

3、The use of internatioal famouse brand electrical components, performance and stability.

4、User can adjust filling range, the materials is not enough in hopper, the computer will give the feeding pump signal to

addmaterial by level sensor. When the material is full, the pump will stop automatically.

5、Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

6、Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

Main Features(Capping machine):

1、The cap elevator and vibrating feeder can be selected according to the shape of the cap and the type of cap

2.、Fast capping speed, adjustable from 0-45 bottles/min

3.、Bottles and caps of different sizes can share a machine by adjusting or changing a few accessories

4.、The tank body of the equipment does not rotate when the cap is screwed, which avoids the displacement, scattering and possible damage of the products contained in the tank.

5、which applied for different cap in different material and different specifications.

6、which use 3-roller type capping knife ,it is easy to regulate the pressure.

7、which applied for metal cap ,screw type cap , pilfer-proofcap, compression cap, etc…

Main Features(Aluminum Foil Sealing Machine):

1、The aluminum foil sealing machine is mainly used for heating and sealing the composite film material sealing and plastic bag sealing with polyolefin (such as polyethylene, polypropylene, etc.) as the inner layer.

2、The thickness of the aluminum foil and the diameter of the seal can be applied within a certain range, and a good and uniform linear seal can be achieved.

3、No matter large bottle, small bottle, long bottle or short bottle can be sealed continuously

4、All the heating parts of the machine adopt air-cooled forced cooling technology, which greatly reduces the manufacturing cost and miniaturizes the equipment.

Anonyme –

Incredible product! The Filling Machine is a true value for money.”