article | valeur |

Condition | Nouveau |

Taper | Machine de remplissage |

Capacité des machines | Autre, 2000HBP, 3000HBP |

Industries applicables | Nourriture & Usine de boissons, Usine esthétique |

Emplacement de la salle d'exposition | Thaïlande |

Application | Nourriture, Boisson, Chimique, Cosmétique |

Type d'emballage | Bouteilles, Autre |

Matériel d'emballage | Plastique, Verre, Autre |

Niveau automatique | Automatique |

Type entraîné | Électrique |

Tension | 220V/380V |

Lieu d'origine | Chine |

Guangdong | |

Marque | Guan Yu |

Dimension(L*L*H) | |

Poids | 1200KG |

garantie | 1 Année |

Points de vente clés | Productivité élevée |

Matériau de remplissage | Bière, Autre, Lait, Eau, Huile, Jus, Liquide, Coller |

Précision de remplissage | 99% |

Rapport d'essai de machines | Fourni |

Inspection vidéo à la sortie | Fourni |

Garantie des composants principaux | 1 Année |

Composants principaux | Récipient sous pression, Pompe, Autre, API |

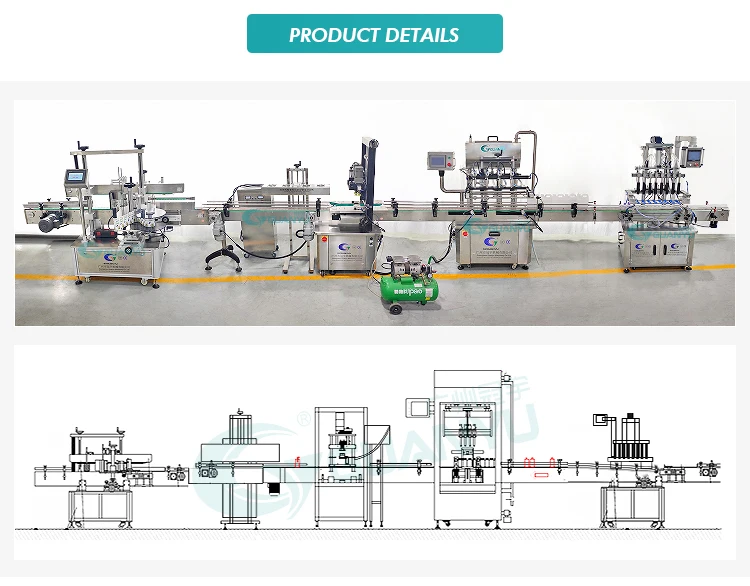

Nom du produit | Filling Production Line |

Fonction | Filling Capping Labeling |

Usage | Paste Cream Sauce Jam Lotion |

Mots-clés | Automatic Filling Line |

Vitesse de remplissage | 1000-3000HBP |

Matériel | Acier inoxydable 304/316 |

Fonctionnalité | High Precision Filling Level |

Plage de remplissage | 500-5000ml(Customisable) |

Contrôle | PLC + écran tactile |

Buches de remplissage | 2/4/6/8/10/12(personnalisé) |

Main Features(Negative ion dust removal machine):

1. Using precise double filtration, electrostatic ion generation ensures that no dust particles remain in the bottle.

2. Automatically store dust particles to ensure clean room air and operator health.

3. You can set the cleaning time according to your needs;

4. Use double (blow/inhale) mouthwash to remove dust from the bottle;

5. Use a precision filter (0.2un) to ensure the cleanliness of the air source;

6. It is suitable for assembly line operations, and can be matched with various assembly lines, with high efficiency

7. This machine can be used in beverage factories, food factories, chemical factories, cosmetics factories, pharmaceutical factories and other enterprises.

Caractéristiques principales (Machine de remplissage):

1. L'équipement a une forte compatibilité, et peut rapidement régler et remplacer les bouteilles de différentes formes et spécifications sans remplacer les pièces, qui peut répondre aux exigences de production de plusieurs variétés et spécifications

2. PLC Contrôle ,opération de bouteille de touche ,opération simple et pratique.

3. L'utilisation de composants électriques de marque Famouse Internatioal, performance et stabilité.

4. L'utilisateur peut ajuster la plage de remplissage, Les matériaux ne suffisent pas à Hopper, L'ordinateur donnera le signal de pompe d'alimentation à

AddMaterial by Level Sensor. Lorsque le matériau est plein, La pompe s'arrêtera automatiquement.

5. Le corps de la machine est fabriqué par 304 acier inoxydable, facile à nettoyer, La machine est pleinement conforme aux exigences GMP.

6. Pompe péristaltique ou système de remplissage de pompe à piston, mesurer la précision, manipulation pratique.

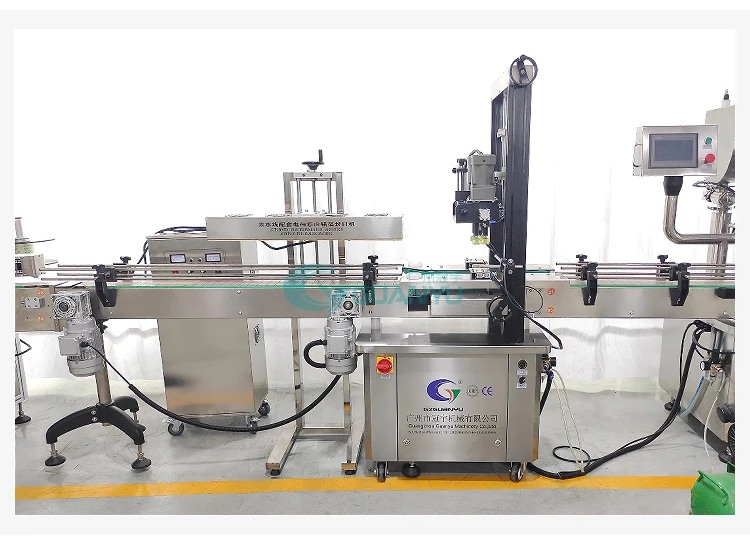

Caractéristiques principales (Machine de plafonnement):

1. L'ascenseur de capuchon et la mangeoire vibrant peuvent être sélectionnés en fonction de la forme du capuchon et du type de capuchon

2. Vitesse de plafonnement rapide, réglable à partir de 0-45 bouteilles / min

3. Les bouteilles et les bouchons de différentes tailles peuvent partager une machine en ajustant ou en modifiant quelques accessoires

4. Le corps du réservoir de l'équipement ne tourne pas lorsque le capuchon est vissé, qui évite le déplacement, diffusion et dommages possibles des produits contenus dans le réservoir.

5. qui s'appliquait à un plafond différent dans différents matériaux et différentes spécifications.

6. qui utilisent un couteau à coiffage de type à 3 rouleaux ,il est facile de réguler la pression.

7. qui s'appliquait à la casquette métallique ,Bouchon de type vis , Cap, capuchon de compression, etc…

Main Features(Labeling Machine):

1. Improve production efficiency, 20-60 pièces / min

2. The whole machine is made of S304 stainless steel and high-grade aluminum alloy, which meets the production requirements of GMP

3. Controlled by PLC man-machine interface, data can be saved, and the data can be directly called when changing the bottle

4. This machine has the mechanism of bottle guiding, bottle dividing, étiquetage, wheel leveling, counting and so on.

5. Wide range of application, labeling position, height and angle can be adjusted.

6. It can be connected to the conveyor belt to be used in the production line

Commentaires

Il n'y a pas encore de critiques.