mono- et diglycérides (Mdg), également connu sous le nom de monoacylglycérols, sont une classe de glycérides composés d'une molécule de glycérol liée à une seule chaîne d'acides gras. Ces composés sont importants en tant qu'additifs alimentaires et émulsifiants, Trouver une utilisation approfondie dans diverses industries, y compris la nourriture, produits de beauté, médicaments, et au-delà. Cet article se penche sur les diverses applications des monoglycérides et souligne l'importance des mélangeurs industriels, récipients de mélange à enveloppe particulière, dans leur production.

1. Applications dans l'industrie alimentaire

Les monoglycérides jouent un rôle crucial dans l'industrie alimentaire en raison de leurs propriétés émulsifiantes., stabilisation, et préserver les propriétés.

Boulangerie et Confiserie

Dans les produits de boulangerie comme le pain, gâteaux, et pâtisseries, les monoglycérides améliorent la plasticité et la stabilité de la pâte, augmenter le volume du pain, et prolonger la durée de conservation. Ils aident à maintenir la douceur et l'humidité des produits de boulangerie, garantir un produit frais et attrayant pour les consommateurs. En confiserie, les monoglycérides empêchent la cristallisation du sucre, améliorer la texture et la brillance des bonbons et des chocolats.

Produits laitiers

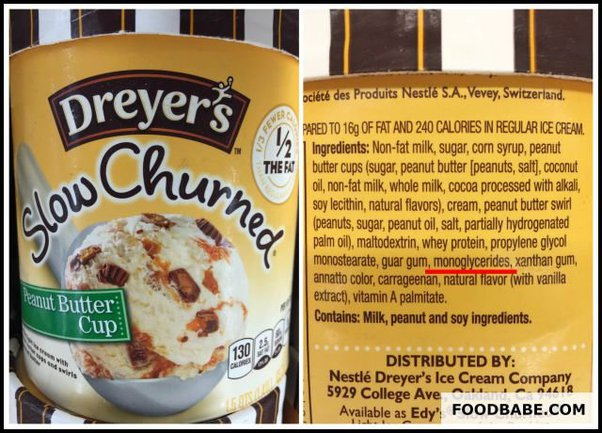

Les monoglycérides font partie intégrante des produits laitiers comme la crème glacée, crème, et du fromage. Ils améliorent la texture, améliorer la sensation en bouche, et empêche la séparation de l'eau et de la graisse. Dans la glace, par exemple, les monoglycérides contribuent à une consistance onctueuse et crémeuse, empêchant la formation de cristaux de glace et assurant une émulsion stable.

Boissons

Dans les boissons comme le lait aromatisé, boissons au café, et jus de fruits, les monoglycérides agissent comme émulsifiants pour empêcher la séparation des ingrédients, garantir un produit uniforme et attrayant. Ils améliorent la stabilité et la consistance de la boisson, maintenir sa qualité pendant le stockage et la consommation.

Plats cuisinés

Les monoglycérides sont utilisés dans les aliments instantanés comme les nouilles instantanées et les aliments surgelés pour améliorer la texture et la sensation en bouche.. Ils améliorent l'expérience culinaire globale en offrant une texture et une consistance souhaitables., rendre ces produits plus savoureux et plus agréables pour les consommateurs.

2. Cosmétiques et produits de soins personnels

Les monoglycérides sont précieux dans l'industrie des cosmétiques et des soins personnels, où ils servent d'émulsifiants, stabilisateurs, et hydratants.

Lotions et crèmes

Dans les lotions et crèmes, les monoglycérides aident à mélanger les phases huileuse et aqueuse pour former des émulsions stables. Il en résulte des produits à la texture lisse, faciles à appliquer et à absorber par la peau.. Les monoglycérides améliorent la stabilité et l'efficacité des ingrédients hydratants et nourrissants, offrir une expérience utilisateur agréable.

Shampoings et revitalisants

Dans les produits de soins capillaires comme les shampoings et les revitalisants, les monoglycérides améliorent l'émulsification et la stabilité de la mousse. Ils contribuent à une mousse riche et rehaussent la douceur et la brillance des cheveux. Les monoglycérides aident à répartir uniformément les agents revitalisants, s'assurer que les cheveux restent lisses, maniable, et d'apparence saine.

Produits de soins de la peau

Les monoglycérides sont utilisés dans divers produits de soin de la peau, y compris les hydratants, nettoyants, et les sérums, pour leurs propriétés hydratantes et émollientes. Ils aident à maintenir l'hydratation de la peau et à créer une barrière protectrice, prévenir la perte d'humidité et améliorer la texture et l'élasticité de la peau.

3. Produits pharmaceutiques et nutraceutiques

Dans les industries pharmaceutique et nutraceutique, les monoglycérides sont utilisés comme excipients et émulsifiants.

Formulations médicamenteuses

Les monoglycérides agissent comme excipients dans les formulations médicamenteuses, faciliter l'administration et l'absorption des ingrédients pharmaceutiques actifs (Apis). Ils améliorent la solubilité et la biodisponibilité des médicaments peu solubles dans l'eau., améliorer leur efficacité thérapeutique. Les monoglycérides aident également à stabiliser les formulations de médicaments, garantir une qualité et des performances constantes.

Suppléments nutritionnels

Les monoglycérides sont utilisés dans les suppléments nutritionnels pour améliorer l'absorption des vitamines liposolubles et d'autres nutriments.. Ils améliorent la biodisponibilité de ces composés, les rendant plus efficaces dans la promotion de la santé et du bien-être. Les monoglycérides sont souvent inclus dans les formulations de vitamines, minéraux, et compléments alimentaires pour améliorer leur stabilité et leur efficacité.

4. Applications industrielles

Au-delà de la nourriture et des soins personnels, les monoglycérides trouvent des applications dans divers processus industriels.

Plastiques et caoutchouc

Dans les industries du plastique et du caoutchouc, les monoglycérides servent de plastifiants et de stabilisants. Ils améliorent les caractéristiques de transformation des polymères, améliorer la flexibilité, durabilité, et la qualité globale des produits finaux. Les monoglycérides aident à prévenir la dégradation pendant le traitement, assurer la production de matériaux plastiques et en caoutchouc de haute qualité.

Textiles

Dans la fabrication textile, les monoglycérides fonctionnent comme lubrifiants et adoucissants, améliorer la douceur et le toucher des fibres. Ils améliorent la manipulation et le traitement des textiles, résultant en des tissus avec une texture et un confort supérieurs. Les monoglycérides contribuent également à la durabilité et à l'apparence des produits textiles.

5. Alimentation animale

En nutrition animale, des monoglycérides sont ajoutés à l'aliment pour améliorer sa valeur nutritionnelle et son appétence.

Additifs alimentaires

Les monoglycérides améliorent la digestibilité et l'absorption des nutriments contenus dans l'alimentation animale, promouvoir une meilleure croissance et une meilleure santé du bétail. Ils améliorent la stabilité et la durée de conservation des formulations alimentaires, garantir que les animaux reçoivent une alimentation constante et de haute qualité. Les monoglycérides sont particulièrement bénéfiques pour améliorer l'absorption des vitamines liposolubles et des acides gras essentiels..

Le rôle de Récipients de mélange à double enveloppe en mono- et diglycérides (Mdg) Production

La production de monoglycérides nécessite un contrôle précis de différents paramètres, y compris la température, vitesse de mélange, et temps de réaction. C'est ici que les mélangeurs industriels, récipients de mélange spécialement revêtus, jouer un rôle central.

Avantages des récipients de mélange à double enveloppe

Les récipients de mélange à double enveloppe sont équipés d'une construction à double paroi, permettant un contrôle précis de la température grâce à la circulation de fluides de chauffage ou de refroidissement dans la chemise. Cela garantit que les conditions de réaction sont maintenues à des niveaux optimaux, crucial pour la production efficace de monoglycérides de haute qualité. Les avantages de l'utilisation de récipients de mélange à double enveloppe dans la production de monoglycérides comprennent:

- Contrôle de la température: Une régulation précise de la température est essentielle pour le processus d'estérification qui produit des monoglycérides. Les récipients à enveloppe permettent un chauffage et un refroidissement précis, garantir des conditions de réaction cohérentes et contrôlées.

- Mélange efficace: Un mélange approprié est essentiel pour obtenir une réaction uniforme et un rendement élevé. Les récipients de mélange à enveloppe sont conçus pour fournir un mélange efficace et complet, éviter la formation de points chauds et assurer un produit homogène.

- Évolutivité: Les récipients de mélange à enveloppe sont disponibles en différentes tailles, ce qui les rend adaptés à la fois à la production en laboratoire à petite échelle et à la fabrication industrielle à grande échelle. Cette évolutivité permet aux fabricants de répondre à diverses demandes de production.

- Versatilité: Les récipients à double enveloppe peuvent être utilisés pour un large éventail de réactions et de processus chimiques, ce qui en fait un outil polyvalent dans la production de monoglycérides et d'autres composés chimiques.

Processus de production de monoglycérides utilisant Récipients de mélange à double enveloppe

- Préparation des matières premières: Le processus commence par la préparation des matières premières, généralement du glycérol et des acides gras. Ces composants sont mesurés et chargés dans le récipient de mélange à double paroi.

- Chauffage et mélange: Le récipient à double enveloppe est chauffé à la température souhaitée, initier la réaction d'estérification. Les contenus sont soigneusement mélangés pour garantir une répartition homogène de la chaleur et une cinétique de réaction efficace..

- Surveillance des réactions: Tout au long du processus, la réaction est étroitement surveillée, et des paramètres tels que la température, pression, et la vitesse de mélange sont ajustées selon les besoins pour maintenir des conditions optimales.

- Refroidissement et récupération: Une fois la réaction terminée, le mélange est refroidi grâce au système de refroidissement du récipient à double enveloppe. Le produit final, monoglycérides, est ensuite récupéré et purifié pour une utilisation ultérieure.

- Contrôle de qualité: Les monoglycérides produits sont soumis à des tests de contrôle de qualité rigoureux pour garantir qu'ils répondent aux normes et spécifications de l'industrie..

Conclusion

Les monoglycérides sont des composés polyvalents avec une large gamme d'applications dans diverses industries. Leur rôle d'émulsifiant, stabilisateurs, et les additifs fonctionnels les rendent inestimables dans l'alimentation, produits de beauté, médicaments, et procédés industriels. La production de monoglycérides repose fortement sur des technologies de mélange avancées, avec des récipients de mélange à double enveloppe jouant un rôle crucial pour garantir une efficacité, évolutif, et une production de qualité.

En tirant parti des capacités des récipients de mélange à double enveloppe, les fabricants peuvent optimiser le processus de production, obtenir des résultats cohérents et répondre à la demande croissante de monoglycérides dans diverses applications. Cette synergie technologique souligne l'importance de l'innovation et de la précision dans l'industrie chimique., faire progresser le développement et l’utilisation de composés essentiels comme les monoglycérides.

J'ai reçu ce site Web de mon ami qui m'a informé de

ce site Web et en ce moment je visite cette page Web et je lis des articles très informatifs ou

avis en ce moment.

Ma page Web coupons nordvpn inspirant

Salut, ouais, cet article est vraiment sympa et j'en ai appris beaucoup de choses concernant

bloguer. merci.

Visitez mon site internet; Coupons Nordvpn Inspiresensation

C'est comme si tu lisais mes pensées! Vous semblez comprendre beaucoup de choses à ce sujet, comme tu l'as écrit

le livre dedans ou quelque chose comme ça. Je pense que tu pourrais en faire quelques-uns %

pour faire passer un peu le message, mais à part ça, c'est un blog fantastique.

Une lecture fantastique. Je reviendrai certainement.

Voici ma page Web; Eharmony Code de coupon spécial 2025

La rédaction d'un article est aussi une excitation, si tu es familier alors tu peux écrire sinon c'est complexe à écrire.

N'hésitez pas à surfer sur mon site Web: VPN

Hé, je voulais juste te donner un aperçu rapide.

Les mots de votre article semblent sortir de l'écran dans Ie.

I’m not sure if this is a formatting issue or something to do with internet browser compatibility but I thought I’d post

to let you know. The layout look great though!

Hope you get the issue solved soon. Thanks gamefly 3

essai gratuit de mois https://tinyurl.com/28555853

Heya je suis pour la première fois ici. I found this board and I find It truly useful & it helped me out much.

I hope to give something back and aid others like you aided me.

What does vpn stand for https://tinyurl.com/2atd6fak

Hi every one, here every person is sharing these experience, therefore it’s fastidious

to read this blog, and I used to pay a quick visit this weblog all the time.

I think everything published made a ton of sense. Cependant, think on this, what if you

added a little content? I am not suggesting your information isn’t good, cependant

what if you added something to maybe grab folk’s attention? I mean mono- et diglycérides (Mdg),Mixing Vessels application is kinda boring.

You ought to peek at Yahoo’s front page and note how they write post headlines to

grab viewers interested. You might try adding a video or a related picture or two to get people interested about everything’ve got to say.

À mon avis, it would make your blog a little bit more interesting.

I always spent my half an hour to read this web site’s articles or reviews everyday along

with a cup of coffee. https://tinyurl.com/yvodnsan Eharmony Code de coupon spécial 2025

Your style is very unique compared to other folks I’ve read stuff from.

I appreciate you for posting when you have the

opportunity, Guess I’ll just bookmark this blog.

ma page; https://tinyurl.com/hwkdwerb

Merci pour votre partage. Je crains de manquer d'idées créatives. C'est ton article qui me donne plein d'espoir. Merci. Mais, J'ai une question, pouvez-vous m'aider?

It’s remarkable for me to have a web site, which is valuable designed for my

expérience. thanks admin vpn https://www.highlandguides.com