Vous voyez que la technologie du vide joue un rôle essentiel dans la fabrication de la mayonnaise. Lorsque vous utilisez des systèmes à vide, vous créez un environnement contrôlé qui empêche l'air de pénétrer dans le mélange. Les émulsifiants sous vide améliorent le processus de mélange et empêche les ingrédients sensibles de s'oxyder. Vous obtenez également un contrôle précis de la température et de la vitesse de mélange, ce qui vous aide à obtenir une fluidité, produit stable.

La technologie du vide améliore le flux de production.

Il préserve la qualité de la mayonnaise.

Vous obtenez une meilleure cohérence et stabilité.

Le décodage des émulsifiants devient plus facile lorsque vous comprenez comment fonctionne la technologie du vide dans la transformation alimentaire réelle..

Principaux à retenir

La technologie du vide empêche l'air de pénétrer dans la mayonnaise, améliorer sa qualité et sa durée de conservation.

L'utilisation d'émulsifiants sous vide permet d'obtenir une texture plus lisse et une meilleure consistance dans la production de mayonnaise..

Un entretien régulier des équipements de vide est crucial pour des performances et une qualité de produit optimales..

Les systèmes sous vide améliorent la sécurité alimentaire en réduisant les risques de contamination pendant la production.

Comprendre les émulsifiants vous aide à contrôler efficacement la texture et la stabilité de la mayonnaise.

Technologie du vide dans la mayonnaise

Décodage des émulsifiants

Vous rencontrez de nombreux types d’émulsifiants lorsque vous étudiez le processus de fabrication de la mayonnaise. Le décodage des émulsifiants vous aide à comprendre comment chaque ingrédient agit pour créer un produit stable. En mayonnaise, vous comptez sur plusieurs émulsifiants clés:

Le jaune d’œuf agit comme émulsifiant principal. Il contient des lipoprotéines de basse densité et de la lécithine, qui stabilise le mélange.

La lécithine est une molécule tensioactive. Il aide l’huile et l’eau à se mélanger et a un numéro HLB compris entre 2 et 8.

Des microparticules granulaires se forment à partir de lipoprotéines de basse densité fusionnées. Ces particules ajoutent au pouvoir émulsifiant.

Vous voyez que les émulsifiants réduisent la tension superficielle de l’eau. Cette action permet à l'huile et à l'eau de se mélanger plus facilement. Les émulsifiants forment des micelles, qui entourent les gouttelettes d’huile et interagissent avec l’eau. Les jaunes d’œufs constituent une riche source de ces molécules. Pendant le processus d'émulsification, les émulsifiants se fixent à la surface des nouvelles gouttelettes. Cela réduit la tension interfaciale et crée une couche protectrice. La couche empêche les gouttelettes de coller ensemble et maintient le mélange lisse.

Vous pouvez consulter la structure de la mayonnaise dans le tableau ci-dessous:

Point clé | Description |

|---|---|

Type d'émulsion | La mayonnaise est une émulsion huile dans eau, même avec une teneur élevée en huile. |

Processus de formation | Mélanger les œufs, vinaigre, et de la moutarde avant d'ajouter de l'huile crée une émulsion stable. |

Structure de l'émulsion | L'émulsion contient des gouttelettes d'huile étroitement tassées, stabilisé par des émulsifiants. |

Le décodage des émulsifiants vous donne les outils nécessaires pour contrôler la texture et la stabilité. Vous utilisez ces connaissances pour sélectionner le bon équipement de transformation des aliments et optimiser le processus de production.

Rôle de l'émulsifiant sous vide

Vous utilisez un émulseur sous vide pour améliorer la qualité et la consistance de la mayonnaise. Cette technologie s'intègre au processus de production et change votre façon d'aborder le mélange et le mélange.. La pompe à vide crée un environnement basse pression. Il extrait les bulles d'air du mélange et empêche l'oxydation. Vous obtenez un, produit plus homogène sans poches d'air.

Voici comment fonctionne un émulsifiant sous vide dans la production de mayonnaise:

L'environnement sous vide améliore le processus d'émulsification en éliminant les bulles d'air.

Moins d’air signifie moins d’oxydation. Cela garde la mayonnaise fraîche et prolonge la durée de conservation.

La fonction vide empêche la formation de mousse. Vous évitez les problèmes de stabilité et d’apparence.

Vous obtenez un crémeux, texture lisse qui correspond aux préférences des consommateurs.

Vous voyez également que la technologie du vide affecte la distribution de la taille des gouttelettes.. Quand tu augmenter la concentration d'émulsifiant, vous diminuez la taille des gouttelettes et augmenter la stabilité. Le tableau ci-dessous montre cette relation:

Concentration d'émulsifiant | Effet de la taille des gouttelettes | Impact sur la stabilité |

|---|---|---|

0.25% | Augmentation de la taille des gouttelettes | Stabilité inférieure |

0.375% | Augmentation de la taille des gouttelettes | Stabilité inférieure |

0.5% | Diminution de la taille des gouttelettes | Une plus grande stabilité |

0.75% | Diminution de la taille des gouttelettes | Une plus grande stabilité |

La technologie du vide prend en charge la production à grande échelle. Vous maintenez la qualité et l’homogénéité des produits tout en réduisant l’incorporation d’air. Cela minimise la détérioration et prolonge la durée de conservation. Vous bénéficiez également de technologies avancées telles que des mélangeurs et homogénéisateurs à haut cisaillement.. Ces machines vous permettent de contrôler la vitesse de mélange et la force de cisaillement. Vous répondez aux exigences modernes d’efficacité et de qualité.

Vous devez conserver votre émulseur sous vide en bon état. Un nettoyage et un entretien réguliers sont importants. Vous vérifiez les scellés, surveiller les températures des roulements, et inspecter l'usure des têtes de mélange. Vous calibrez les capteurs et nettoyez les systèmes de refroidissement. Vous vérifiez les performances de la pompe à vide et remplacez les pièces usées au besoin. La formation des opérateurs vous aide à maximiser l’efficacité et éviter les erreurs.

La technologie du vide vous donne un avantage dans la production alimentaire. Vous produisez une mayonnaise avec une meilleure texture, saveur, et durée de conservation. Vous répondez aux attentes des consommateurs et positionnez votre produit sur des marchés premium. Le décodage des émulsifiants et l’utilisation d’émulsifiants sous vide vous aident à atteindre ces objectifs.

Processus d'émulsification et qualité du produit

Formation d'émulsion stable

Vous jouez un rôle clé dans le processus de fabrication de la mayonnaise lorsque vous utilisez la technologie sous vide. Cette technologie vous aide à créer un émulsion stable en éliminant les bulles d'air lors du mélange. Les bulles d'air peuvent affaiblir la structure de la mayonnaise et raccourcir sa durée de conservation. Quand vous utilisez un aspirateur, vous obtenez un produit plus dense et plus stable. Vous améliorez également la qualité et la consistance de la mayonnaise.

Pour obtenir une émulsion stable, vous devez contrôler plusieurs paramètres importants. Le tableau ci-dessous montre ce sur quoi vous devez vous concentrer:

Paramètre | Explication |

|---|---|

Émulsifiants appropriés | Vous avez besoin du bon émulsifiant pour empêcher les gouttelettes d’huile de se regrouper et maintenir l’émulsion stable.. |

Homogénéisation | Vous utilisez un homogénéisateur pour fabriquer de petites gouttelettes d'huile, ce qui aide à prévenir la séparation et garde la mayonnaise lisse. |

Mélange sous vide | Vous utilisez le mélange sous vide pour réduire l'air dans le mélange, ce qui permet à l'émulsion de durer plus longtemps. |

Vous avez également besoin de suffisamment d’énergie pour briser la barrière entre le pétrole et l’eau.. Les mélangeurs et homogénéisateurs à cisaillement élevé vous aident à produire des gouttelettes plus petites. Cette étape est importante pour le processus d'émulsification. Vous devez équilibrer les forces à la surface des gouttelettes pour les empêcher de se rejoindre.. Lorsque vous utilisez la technologie du vide, vous vous assurez que la mayonnaise reste crémeuse et uniforme.

Élimination des odeurs et cohérence

La technologie du vide fait plus que simplement contribuer à une émulsification stable. Vous l'utilisez également pour éliminer les odeurs indésirables de la mayonnaise. Les dégazeurs sous vide extraient les gaz dissous et les composés volatils qui peuvent provoquer des odeurs désagréables.. Cette étape améliore le goût et l'odeur de la mayonnaise, le rendant plus attrayant pour les consommateurs.

Voici quelques façons dont les dégazeurs sous vide vous aident:

Ils éliminent les odeurs spécifiques, donner un meilleur goût et une meilleure odeur à la mayonnaise.

Ils arrêtent l'oxydation, ce qui maintient la saveur et la texture stables.

Ils extraient les gaz qui peuvent provoquer des odeurs désagréables dans la mayonnaise..

La technologie du vide vous aide également à obtenir la bonne consistance. Vous utilisez un homogénéisateur et des mélangeurs à haut cisaillement pour vous assurer que la mayonnaise est lisse et uniforme.. Le tableau ci-dessous montre comment la technologie du vide favorise la cohérence et la qualité.:

Fonctionnalité | Avantage |

|---|---|

Vous obtenez une texture uniforme et une mayonnaise consistante. | |

Dispositif à haut cisaillement | Vous faites de très petites gouttelettes d'huile, qui arrête les bulles et donne une texture onctueuse. |

Technologie du vide | Vous ajoutez des ingrédients sous la surface, ce qui permet de les mélanger instantanément et d'éviter les défauts. |

Réduit le mélange d’air et la formation de mousse | Vous évitez les agglomérations et les grumeaux indésirables, améliorer la mayonnaise pour un usage alimentaire. |

Lorsque vous utilisez la technologie du vide dans la production alimentaire, vous augmentez l'efficacité et améliorez le produit final. Vous obtenez une mayonnaise avec une meilleure texture, durée de conservation plus longue, et un goût qui répond à des normes élevées. Vous vous assurez également que votre équipement de transformation alimentaire fonctionne de manière optimale à chaque étape de la production..

Comparaison des méthodes de fabrication de la mayonnaise

Traditionnel vs. Émulsifiant de vide

Quand on regarde le processus de fabrication de la mayonnaise, vous voyez de grandes différences entre les méthodes traditionnelles et l'utilisation d'un émulseur sous vide. De manière traditionnelle, tu mélanges les jaunes d'oeufs, vinaigre, et huiler à la main ou avec des machines simples. Cette méthode conduit souvent à une mauvaise stabilité et à une texture grossière. L'air reste emprisonné dans le mélange, ce qui peut provoquer des agglomérations et de la mousse. Vous remarquerez peut-être également que la mayonnaise préparée de cette façon a une durée de conservation plus courte et est plus susceptible de se séparer..

Avec un émulseur sous vide, vous utilisez une technologie de pointe pour améliorer chaque étape. Vous commencez par dissoudre le saccharose dans du vinaigre. Alors, tu mélanges le jaune d'oeuf, moutarde, et des épices pour former un liquide uniforme. Vous ajoutez alternativement de l'huile et du vinaigre par aspiration sous vide. Ce processus élimine l'air et vous aide à créer une émulsion huile-dans-eau stable.. Vous utilisez un homogénéisateur et des mélangeurs à cisaillement élevé pour décomposer les gouttelettes d'huile, rendre la mayonnaise onctueuse et crémeuse. Le système de vide permet également de stériliser le produit, ce qui augmente la sécurité.

Étape | Méthode traditionnelle | Méthode d'émulsification sous vide |

|---|---|---|

1 | Ajouter les jaunes d'œufs et le vinaigre, puis huiler manuellement | Dissoudre d'abord le saccharose dans le vinaigre |

2 | Remuer jusqu'à ce qu'il soit semi-solide | Mélanger le jaune d'oeuf, moutarde, et des épices pour former un liquide uniforme |

3 | Ajouter toute l'huile d'un coup | Ajouter l'huile et le vinaigre en alternance par aspiration sous vide |

4 | Mélanger dans le réservoir émulsionneur | Mélanger de petites quantités et utiliser l'homogénéisation pour l'uniformité |

5 | Aucune étape de stérilisation | Stériliser à température contrôlée |

6 | Le produit peut se délaminer | Stabilité et texture améliorées grâce au processus sous vide |

Efficacité et sécurité

Vous bénéficiez de nombreux avantages lorsque vous utilisez la technologie du vide et des équipements avancés dans la production de mayonnaise.. Les homogénéisateurs émulsifiants sous vide et les mélangeurs à cisaillement élevé vous aident à économiser du temps et de l'énergie. Le système de vide désaère le produit rapidement, ce qui réduit le temps de production jusqu'à 60%. Vous consommez également moins d’énergie car les étapes de mélange et de nettoyage sont plus rapides.

Métrique | Description |

|---|---|

Temps de production | Peut réduire le temps de production de 60% |

Consommation d'énergie | Un mélange et un nettoyage plus rapides permettent d'économiser de l'énergie |

Efficacité de mélange | Un système unique permet une dispersion rapide |

Les homogénéisateurs émulseurs sous vide rendent votre processus de production plus efficace. Vous pouvez incorporer de l'huile ou de la poudre environ cinq fois plus rapide qu'avec les mélangeurs traditionnels. Cela signifie que vous pouvez produire plus de mayonnaise en moins de temps. Vous améliorez également la sécurité alimentaire. Le système de vide réduit le risque de contamination en éliminant l'air et en permettant la stérilisation. Votre mayonnaise aura plus stabilité de l'émulsion, texture plus lisse, et une durée de conservation plus longue.

Lorsque vous utilisez la technologie du vide, vous obtenez une mayonnaise qui répond à des normes élevées de qualité alimentaire. Vous rendez également votre production plus sûre et plus efficace. L'intégration du vide, homogénéisateur, et les mélangeurs à cisaillement élevé dans les équipements de transformation des aliments vous donnent un contrôle total sur le produit final.

Tu vois comment la technologie du vide transforme production de mayonnaise. Lorsque vous utilisez un émulseur sous vide et un homogénéisateur, vous réalisez mayonnaise plus douce, meilleure stabilité, et une durée de conservation plus longue. Vous améliorez également la sécurité alimentaire et réduisez les déchets.

Vous obtenez une texture et une saveur constantes dans chaque lot.

Vous accélérez la production et réduisez les risques de contamination.

Vous répondez à des normes strictes de tests de contrôle de qualité.

Tendances futures de la technologie alimentaire | Description |

|---|---|

Systèmes de vide intelligents | Surveillance en temps réel et économies d'énergie |

Emballage écologique | Soutient la durabilité dans la production alimentaire |

Vous pouvez vous attendre à ce que la technologie du vide façonne l’avenir de la mayonnaise et de la production alimentaire..

FAQ

À quoi sert la technologie du vide dans la production de mayonnaise?

Vous utilisez la technologie du vide pour éliminer l’air du mélange. Cette étape vous aide à réaliser une mayonnaise à la texture onctueuse. Il permet également de conserver la fraîcheur du produit pendant la production.

Pourquoi l'élimination de l'air est-elle importante dans la production de mayonnaise?

L'élimination de l'air empêche la formation de bulles dans la mayonnaise. Vous obtenez un produit stable qui ne se sépare pas. Ce processus vous aide également à maintenir une qualité élevée pendant la production.

Comment la technologie du vide améliore-t-elle la cohérence des produits?

Vous utilisez des systèmes sous vide pour mélanger les ingrédients uniformément. Cette méthode vous donne une mayonnaise avec la même texture à chaque fois. Cela vous aide également à éviter les grumeaux pendant la production.

La technologie du vide peut-elle contribuer à la sécurité alimentaire dans la production?

Oui. Vous utilisez des équipements sous vide pour réduire les risques de contamination. Cette étape vous aide à conserver la mayonnaise en sécurité pendant la production et le stockage..

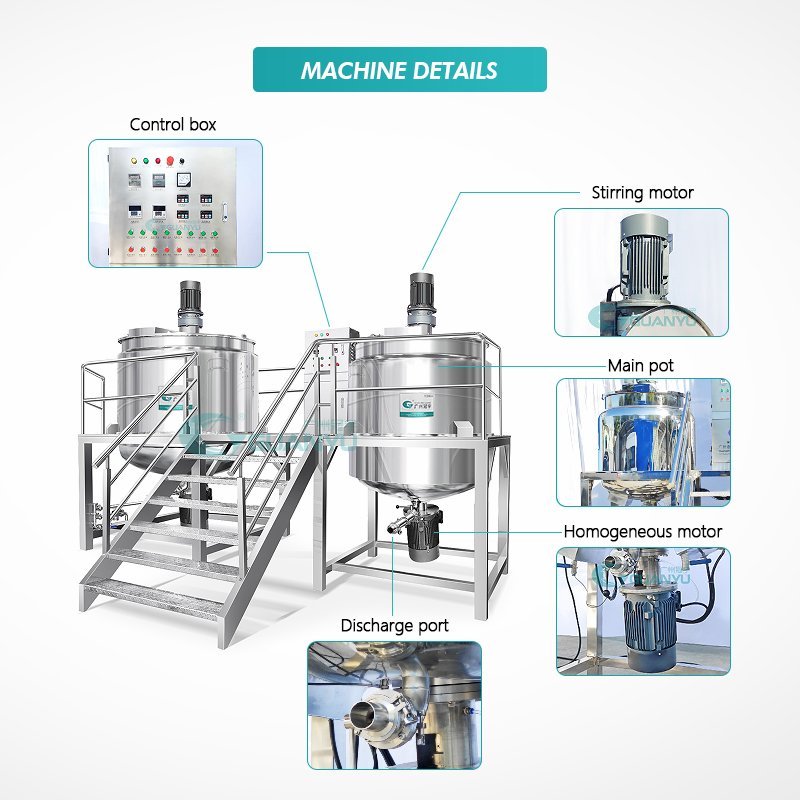

De quel équipement avez-vous besoin pour la production de mayonnaise sous vide?

Vous avez besoin d'un émulseur sous vide, un mélangeur à haut cisaillement, et un homogénéisateur. Ces machines vous aident à contrôler chaque étape de la production et vous garantissent d'obtenir les meilleurs résultats..

J'ai entendu du buzz à propos de ph222casino.com. Je l'ai essayé, et honnêtement, pas trop mal! Bonne sélection de jeux et les paiements sont légitimes. Mon avis est que vous devriez le vérifier avec ce lien: ph222casino

234Winph a le branchement avec des tonnes de bonus! J'ai commencé avec 300, et j'ai gagné 3000! J'étais si heureux. Vous pouvez en savoir plus ici 234Winph.

Votre article m'a beaucoup aidé, y a-t-il d'autres contenus connexes? Merci!

Votre point de vue m'a interpellé et a été très intéressant. Merci. j'ai une question pour toi. https://www.binance.info/register?ref=IXBIAFVY