Machines à mélangeurs cosmétiques, Machines émulsifiant spécifiquement sous vide, ont transformé la façon dont les soins de la peau et les produits de beauté sont produits. Ces machines sont cruciales pour mélanger des formulations complexes qui se composent d'huiles, eau, et ingrédients actifs, Création de stable, Émulsions de haute qualité pour des produits comme les lotions, crèmes, sérums, et plus. Le contrôle précis de l'émulsification, texture, and temperature ensures that cosmetic brands can deliver consistent and effective products. Dans cet article, we will explore the process behind cosmetic mixer machines, their various applications in beauty product manufacturing, and the benefits they offer.

How Cosmetic Mixer Machines Work

Cosmetic mixer machines are designed to blend different ingredients efficiently, producing smooth and stable emulsions. These machines typically work through the following processes:

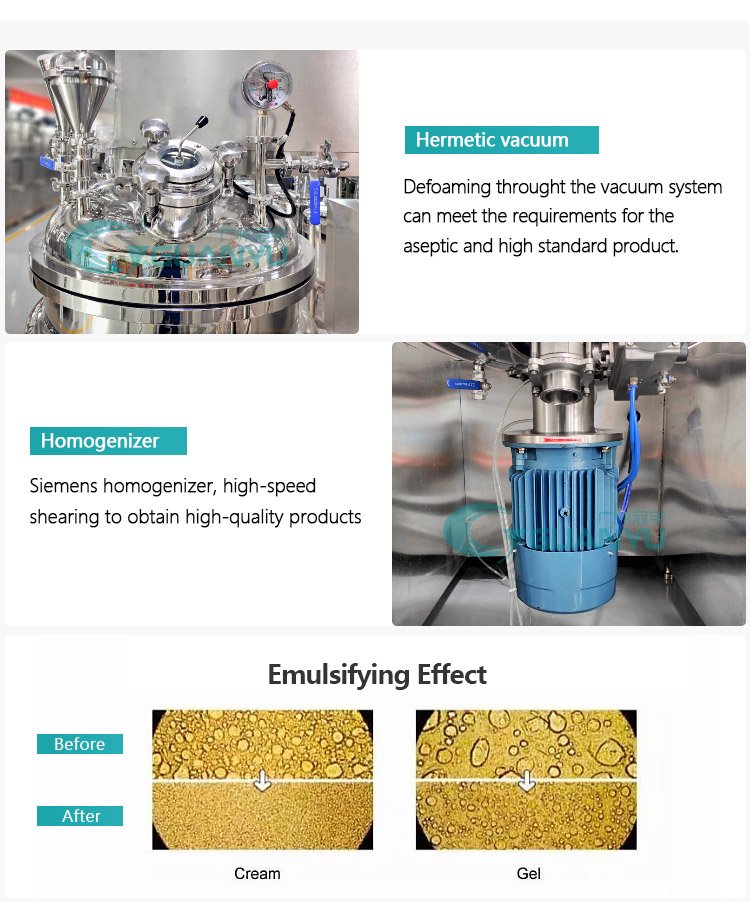

- Homogénéisation: Ingredients such as oils, eau, and other active elements need to be mixed into a uniform product. The machine uses high-speed shear forces to break down oil droplets and distribute them evenly throughout the water base, résultant en une émulsion stable. This is crucial for the product’s consistency and quality.

- Vacuum Deaeration: One of the unique features of these machines is their vacuum function, which removes air from the mixture. This step prevents bubbles from forming and ensures that the product is free from air pockets, enhancing the overall texture and appearance of the product.

- Contrôle de la température: Cosmetic mixer machines are equipped with advanced heating and cooling systems to control the temperature during production. Some ingredients require specific temperatures to emulsify or stabilize correctly, and the machine ensures the process is optimized.

- Mixing and Shearing: The high-shear mixer inside the machine rotates rapidly, combining ingredients effectively. This action helps create a smooth, texture uniforme, breaking down any larger particles and ensuring that the product is consistent throughout.

Applications of Cosmetic Mixer Machines in the Beauty Industry

Cosmetic mixer machines are indispensable in producing various beauty and skincare products. Here are some of the key applications:

- Creams and Moisturizers: One of the most common uses for cosmetic mixer machines is in producing moisturizers and creams. These products rely heavily on emulsification, where oils and water are combined to form a stable, smooth cream. The machine ensures that active ingredients like vitamins and antioxidants are evenly dispersed, improving the effectiveness and texture of the final product.

- Lotions: Cosmetic mixer machines are essential in making lotions, which require a lighter consistency than creams. The emulsifying process helps create a fluid product that spreads easily on the skin, providing hydration without being too thick.

- Serums and Gels: Serums and gels are typically lightweight products that need to be produced under precise conditions to maintain their active ingredients’ efficacy. The vacuum technology in the mixer machines prevents oxidation and contamination, which is crucial for maintaining the integrity of the product.

- Crèmes solaires: Sunscreens contain active UV filters that need to be evenly distributed throughout the product for effective protection. Cosmetic mixer machines ensure that these filters are properly mixed with other ingredients, creating a smooth, stable product that provides consistent sun protection.

- Shampoings et revitalisants: In haircare products, emulsifying machines help blend oils, agents de conditionnement, and surfactants to create formulas that clean, soften, and protect the hair. These machines ensure that ingredients like silicones are evenly distributed for the best performance.

Avantages Machines de mélange cosmétique in Manufacturing

The use of cosmetic mixer machines offers several benefits to manufacturers, ensuring both product quality and production efficiency:

- Enhanced Product Stability: Cosmetic mixer machines ensure that emulsions are stable, meaning that the water and oil phases do not separate. This is essential for maintaining the product’s shelf life and effectiveness.

- Consistent Texture and Quality: By using high-speed shearing and vacuum technology, the machine produces products with a fine, smooth texture that is free from imperfections like lumps or bubbles. This consistency is key to producing high-quality creams, lotions, and gels that customers expect from premium beauty brands.

- Preservation of Active Ingredients: Many skincare products contain sensitive active ingredients, such as antioxidants, peptides, and vitamins, which can degrade if exposed to air or heat. The vacuum environment and precise temperature control help preserve these ingredients, ensuring that the final product delivers the desired benefits.

- Reduced Air Contamination: The vacuum function not only improves product texture but also prevents airborne particles and contaminants from entering the product. This results in a purer, more hygienic formulation, especially important for luxury skincare products and dermatological treatments.

- Efficacité de production accrue: With automated controls for speed, température, et le temps de mélange, cosmetic mixer machines make production more efficient. Manufacturers can produce large batches consistently, reducing the time and labor needed for manual mixing processes. This boosts overall productivity and ensures that each batch meets the same high standards.

Future Innovations in Cosmetic Mixer Machines

As the cosmetics industry continues to grow and evolve, the role of cosmetic mixer machines will likely expand with new technological advancements. Key trends expected in the future include:

- Automated and Smart Technology: Future cosmetic mixer machines are expected to feature even more sophisticated automation, enabling precise adjustments to mixing speed, shear force, et la température. These smart machines will provide real-time feedback, allowing manufacturers to fine-tune the production process for optimal results.

- Sustainability and Green Production: With an increasing focus on sustainability in the beauty industry, there is growing demand for energy-efficient cosmetic mixer machines. These machines will be designed to minimize waste, reduce energy consumption, and support environmentally-friendly formulations, aligning with the eco-conscious values of modern consumers.

- Customization for Niche Markets: As personalized beauty products continue to rise in popularity, the need for small-batch production is becoming more critical. Future mixer machines will likely offer flexible, scalable production options, enabling brands to create bespoke, customized products for niche markets while maintaining the same level of precision and quality as in large-scale production.

Conclusion

Cosmetic mixer machines have revolutionized the production of beauty and skincare products, making it possible for brands to create high-quality, stable formulations efficiently. From creams and lotions to serums, gels, et écran solaires, these machines are critical in ensuring that products meet the highest standards in terms of texture, stabilité, and efficacy. With advancements in automation, durabilité, et personnalisation, cosmetic mixer machines will continue to play a vital role in the future of the beauty industry.

J'ai entendu du bruit à propos de 6566pari1. Apparemment, ils ont des machines à sous exclusives. Je vais créer un compte et voir si ça vaut le coup.

Bien, 77pub is keeping it real. Simple design, working games. If you need somewhere low-key to throw down a few bets, ça pourrait être ça. Essayez-le! Right here: 77pub

Votre article m'a beaucoup aidé, y a-t-il d'autres contenus connexes? Merci!

Je ne pense pas que le titre de ton article corresponde au contenu mdr. Je plaisante, principalement parce que j'ai eu quelques doutes après avoir lu l'article. https://www.binance.info/pt-BR/register?ref=GJY4VW8W