Le calcul de vos coûts vous donne une voie claire lorsque vous souhaitez mettre en place une ligne de production de mayonnaise. Il faut regarder l'équipement, matières premières, travail, conditionnement, et les règles qui affectent vos coûts. L’échelle de production modifie vos dépenses et la manière dont vous contrôlez la qualité. Si tu planifies bien, vous pouvez faire de la mayonnaise efficacement et éviter le gaspillage.

Principaux à retenir

Comprendre les principaux éléments de coût comme les matières premières, travail, et emballages pour gérer efficacement vos dépenses de production de mayonnaise.

Calculez votre marge brute pour assurer la rentabilité. Une marge plus élevée permet des opportunités de réinvestissement et de croissance.

Choisissez la bonne échelle de production en fonction de votre budget et de la demande du marché. Commencer petit peut vous aider à apprendre et à grandir progressivement.

Investissez dans l’automatisation pour réduire les coûts de main-d’œuvre et améliorer l’efficacité. Les machines automatisées peuvent travailler plus longtemps avec moins de temps d'arrêt.

Restez informé des réglementations et des certifications en matière de sécurité alimentaire pour éviter les amendes et renforcer la confiance des clients..

Calculer vos coûts pour la production de mayonnaise

Éléments clés des coûts

Quand vous commencez à calculer vos coûts pour une ligne de production de mayonnaise, vous devez décomposer chaque partie de votre processus. Vous devez examiner chaque coût pour voir comment il affecte vos dépenses totales et vos bénéfices.. Les experts du secteur recommandent de suivre les coûts dans des catégories claires. Cela vous aide à voir où va votre argent et comment vous pouvez améliorer votre entreprise..

Voici un tableau qui présente les principales catégories de coûts pour les producteurs de mayonnaise:

Catégorie de coût | Description |

|---|---|

Coûts de traitement par lots | Intrants tels que les matières premières, ingrédients, et matériaux d'emballage utilisés dans les cycles de production. |

Coûts de main-d'œuvre | Main d'œuvre variable ou fixe des lignes de lavage, tri manuel, classement, ou des équipes d'emballage. |

Frais de transport | Frais de transport et de livraison par palette ou par unité qui doivent être correctement répartis. |

Coûts fixes | Amortissement du matériel, électricité, frais généraux, ou des éléments de travail cohérents qui peuvent être négligés. |

Transparence des coûts | Lier chaque lot à ses entrées, services, et les frais généraux pour calculer le coût réel par unité. |

Analyse de rentabilité | Génération de tableaux de bord pour analyser la rentabilité sur plusieurs lots, clients, et catégories de produits. |

Vous devez faire attention aux coûts de traitement par lots. Ceux-ci incluent les œufs, huile, vinaigre, et autres ingrédients que vous utilisez pour faire de la mayonnaise. Les coûts de main d'œuvre couvrent les personnes qui travaillent sur votre ligne de production de mayonnaise. Les coûts de transport sont importants lorsque vous expédiez votre produit pour répondre à la demande du marché de la mayonnaise.. Les coûts fixes comprennent des éléments comme l'équipement et l'électricité. La transparence des coûts vous aide à voir le coût réel de chaque lot. L'analyse de rentabilité vous permet de suivre les produits et les clients qui vous rapportent le plus de bénéfices..

Si vous souhaitez mettre en place une ligne de production de mayonnaise, vous devez comprendre ces catégories. Vous pouvez utiliser des tableaux de bord ou des feuilles de calcul pour suivre chaque coût. Cela facilite le calcul de vos coûts et vous aide à prendre de meilleures décisions.

Pourquoi le calcul des coûts est important

Calculer vos coûts n’est pas qu’une question de chiffres. Il vous aide à maintenir votre entreprise forte et prête à faire face aux changements de la demande ou du marché.. Vous devez savoir combien d'argent vous dépensez pour fabriquer chaque pot de mayonnaise.. Cela vous permet de fixer des prix qui couvrent vos coûts et vous rapportent un bénéfice.

“Bouchard souligne l’importance de connaître la marge brute de l’entreprise, qui est calculé comme la différence entre les revenus et les coûts des marchandises vendues (communément appelé COGS), divisé par le chiffre d’affaires et exprimé en pourcentage.”

La marge brute vous indique combien d'argent vous conservez après avoir payé les ingrédients, travail, et autres frais. Si votre marge brute est trop faible, vous pourriez avoir du mal à vendre votre mayonnaise ou à développer votre entreprise. Si votre marge est élevée, vous avez plus de marge pour investir et vous développer.

Voici un tableau qui montre ce que signifient les différentes marges brutes pour les producteurs de mayonnaise.:

Plage de marge brute | Implication |

|---|---|

Ci-dessous 50% | Difficulté de distribution et de tarification |

70-80% | Sérieuse opportunité de croissance |

“Cependant, qui comporte des risques considérables, surtout si le prix de votre produit est nettement supérieur à celui de vos concurrents.”

Vous devez faire attention aux risques lors du calcul de vos coûts. Si vous sous-estimez vos dépenses, tu peux avoir des ennuis. Voici quelques risques courants:

Démarrer une entreprise de mayonnaise implique diverses dépenses générales qui doivent être budgétisés de manière stratégique.

Sous-estimer ces coûts peut entraîner des difficultés financières et des pertes potentielles.

Une bonne budgétisation est essentielle pour éviter les risques financiers inattendus.

Vous devez planifier chaque coût, des ingrédients au transport. Cela vous aide à éviter les surprises et à assurer le bon fonctionnement de votre ligne de production de mayonnaise.. Quand vous comprenez vos coûts, vous pouvez répondre aux changements dans la demande du marché de la mayonnaise et garder une longueur d'avance sur vos concurrents. Le calcul de vos coûts vous donne le pouvoir de développer votre entreprise et de répondre à la demande du marché..

Définissez l'échelle de votre ligne de production de mayonnaise

Petit contre. Grande production

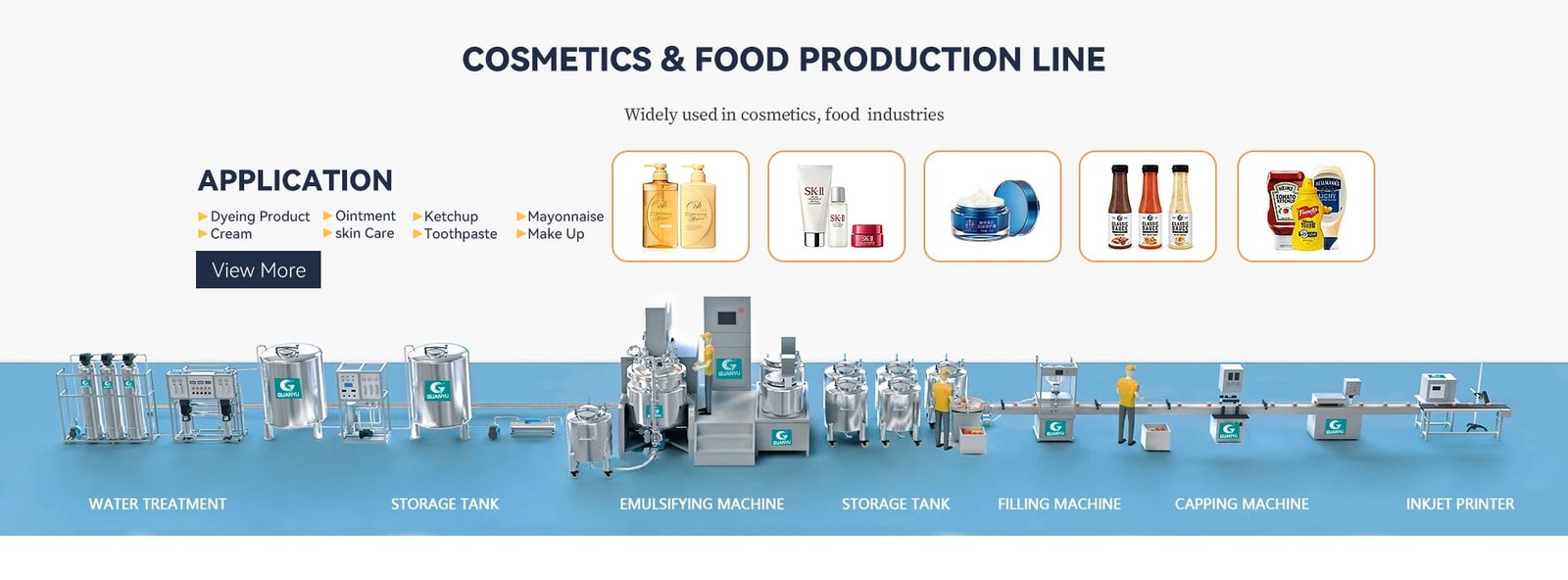

Vous devez décider si vous souhaitez démarrer avec une petite ou une grande ligne de production de mayonnaise.. Ce choix façonne vos besoins en équipements et votre premier investissement. La production à petite échelle utilise souvent de simples mélangeurs et des machines de remplissage manuelles. Vous pouvez commencer avec moins d’argent et grandir à mesure que vous apprenez le métier.. Si vous choisissez une opération à grande échelle, vous devez prévoir un rendement plus élevé et des machines plus avancées. Les grandes usines utilisent Mélangeurs émulsifiant sous vide pour gérer de gros lots et maintenir une qualité élevée. Ces machines coûtent plus cher, mais ils vous aident à répondre à la forte demande du marché de la mayonnaise et à suivre la concurrence.. Votre décision dépend de la quantité de mayonnaise que vous souhaitez préparer et de la rapidité avec laquelle vous souhaitez vous développer sur le marché..

Type de mayonnaise et impact sur les coûts

Le type de mayonnaise que vous produisez modifie également vos coûts. Chaque type a ses propres besoins et prix. Voici quelques façons dont différents types affectent vos dépenses de production:

La mayonnaise bio coûte plus cher parce que vous avez besoin d'ingrédients biologiques et devez suivre des règles de certification strictes.

La mayonnaise faible en gras nécessite souvent des recettes spéciales et des étapes supplémentaires, ce qui peut augmenter vos coûts de production.

La mayonnaise classique utilise des ingrédients standards, donc ça coûte généralement moins cher à faire.

La mayonnaise aromatisée ou spéciale peut nécessiter des ingrédients uniques, ce qui peut augmenter à la fois les coûts des ingrédients et de l'emballage.

Vous devez réfléchir à ce que veulent vos clients et à ce que le marché attend. Si vous choisissez un produit premium, vous dépenserez plus en ingrédients et en processus. Si vous privilégiez la mayonnaise classique, vous pouvez réduire les coûts et atteindre un public plus large. Vos choix en matière d'échelle de production et de type de produit façonneront votre investissement et votre place sur le marché de la mayonnaise..

Répartition des coûts pour la mise en place d'une ligne de production de mayonnaise

Quand vous installez une ligne de production de mayonnaise, vous devez comprendre où va votre argent. Chaque partie du processus a ses propres coûts. Connaître ces coûts vous aide à planifier votre investissement et à contrôler vos dépenses. Décomposons les principaux domaines à prendre en compte.

Équipements et machines

Vous avez besoin des bonnes machines pour préparer efficacement de la mayonnaise. Le type de machine à mayonnaise que vous choisissez dépend de votre échelle de production et de la qualité souhaitée.. Mélangeurs à haut cisaillement et les équipements automatisés jouent un rôle important dans le contrôle du coût de la mayonnaise. Ces machines mélangent les ingrédients rapidement et uniformément, ce qui permet de gagner du temps et de réduire les déchets. Ils vous aident également à utiliser plus efficacement des ingrédients coûteux.

Les mélangeurs à cisaillement élevé utilisent un système rotor-stator pour décomposer les particules et mélanger les ingrédients. Cela rend votre mayonnaise onctueuse et homogène. Les machines automatisées maintiennent votre production stable et réduisent les erreurs.

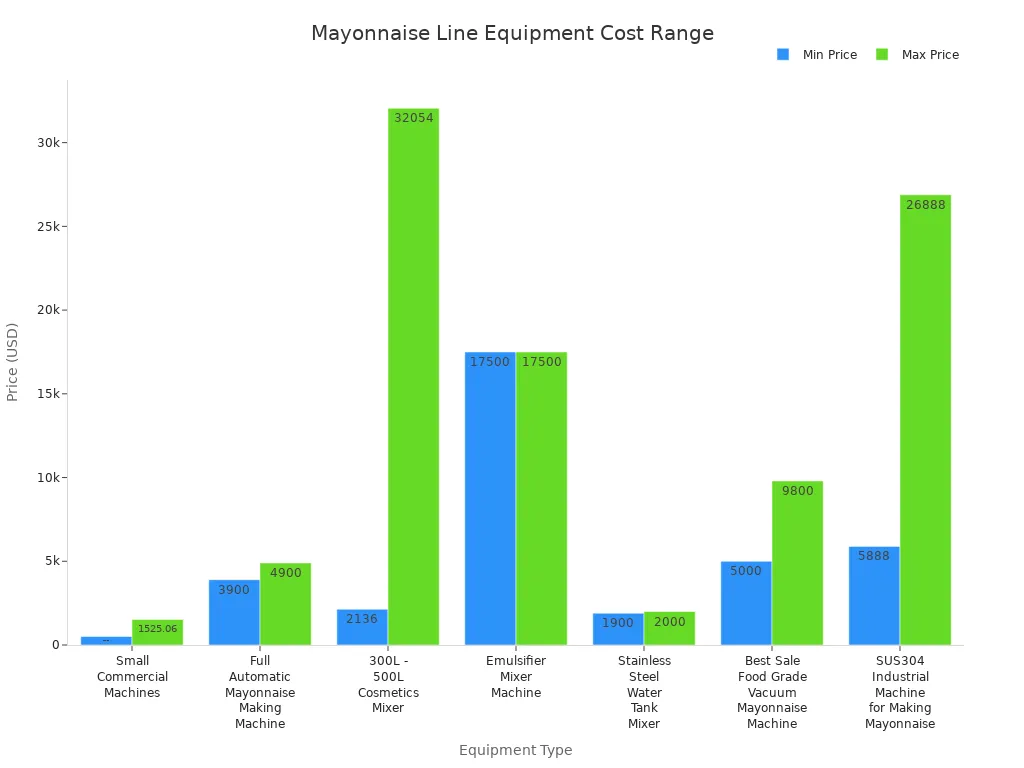

Voici un tableau montrant le fourchette de prix typique pour les équipements essentiels:

Type d'équipement | Fourchette |

|---|---|

Petites machines commerciales | $508.35 – $1,525.06 |

Machine de fabrication de mayonnaise entièrement automatique | $3,900 – $4,900 |

300L – 500Mélangeur de cosmétiques L | $2,136 – $32,054 |

Mélangeur émulsifiant | $17,500 |

Mélangeur de réservoir d'eau en acier inoxydable | $1,900 – $2,000 |

Machine à mayonnaise sous vide de qualité alimentaire, meilleure vente | $5,000 – $9,800 |

Machine industrielle SUS304 pour fabriquer de la mayonnaise | $5,888 – $26,888 |

Quand vous envisagez d'acheter une machine à mayonnaise, pensez à vos besoins de production et à votre croissance future. Investir dans des systèmes automatisés peut réduire vos coûts de production à long terme. Ces machines vous aident également à répondre à la demande du marché de la mayonnaise en fonctionnant plus longtemps avec moins de temps d'arrêt..

Coûts matériels directs

Les coûts matériels directs représentent la plus grande partie de vos dépenses. Pour la plupart des producteurs de mayonnaise, ces coûts représentent environ 51% du chiffre d'affaires total. Tu dois acheter des œufs, huile, vinaigre, et d'autres ingrédients. La qualité et le type d'ingrédients affectent vos coûts et le produit final.

Si vous souhaitez faire de la mayonnaise biologique ou de spécialité, vous paierez plus pour les ingrédients certifiés. Acheter en gros peut vous aider à économiser de l’argent, mais vous devez équilibrer cela avec le stockage et la durée de conservation. Le suivi de vos coûts directs de matières vous aide à voir où vous pouvez économiser et comment ajuster vos recettes pour répondre à la demande du marché..

Travail et dotation en personnel

La main d’œuvre est un autre coût clé dans le processus de production de mayonnaise. Vous avez besoin de travailleurs pour faire fonctionner les machines, vérifier la qualité, et emballer les produits. L'automatisation peut vous aider à réduire les besoins en main-d'œuvre. Les machines à mayonnaise automatisées gèrent les tâches répétitives, vous avez donc besoin de moins de travailleurs pour les opérations de base.

Les machines peuvent fonctionner 24/7, pour ne pas payer d'heures supplémentaires.

Vous dépensez moins en formation et en recrutement de nouveau personnel.

Les travailleurs peuvent se concentrer sur le contrôle de la qualité et la sécurité.

En utilisant des systèmes automatisés, vous réduisez vos coûts de main d’œuvre et rendez votre production plus efficace. Cela vous aide à rester compétitif sur le marché.

Emballage et étiquetage

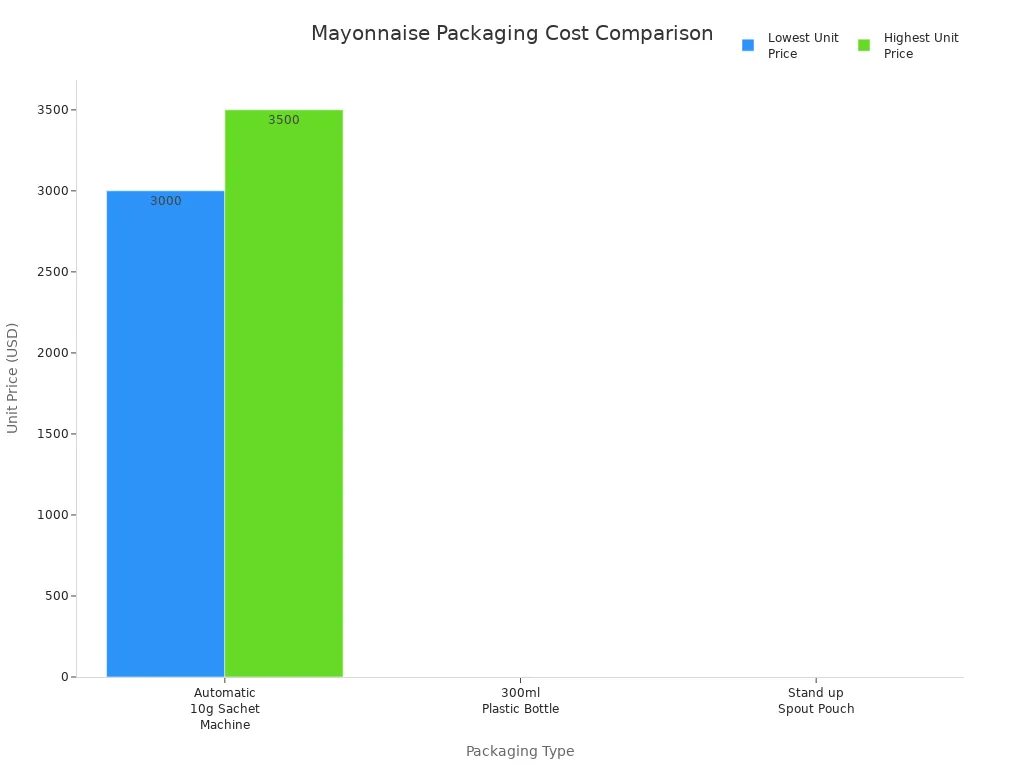

L'emballage protège votre mayonnaise et lui donne une belle apparence dans les rayons des magasins. Le type d'emballage que vous choisissez affecte vos coûts et la durée de conservation de votre produit. Voici un tableau avec options d'emballage et prix typiques:

Type d'emballage | Fourchette | Prix unitaire | MOQ | Attributs clés |

|---|---|---|---|---|

Machine de conditionnement automatique de sachet de petite poche de la mayonnaise 10g | $3,000-3,500 | Ensemble | 1 ensemble | Automatisation d'entrée de gamme, adapté aux petits sachets. |

300Bouteille de mayonnaise en plastique ml avec bouchon à vis | $0.30-0.38 | Morceau | 5,000 pièces | Solution en bouteille rigide, PEHD/PP alimentaire. |

Pochette à bec debout de qualité alimentaire imprimée sur mesure | $0.04-0.06 | Morceau | 30,000 pièces | Option d'impression personnalisée, prix compétitif en volume. |

Différents matériaux d'emballage modifient également vos coûts et la stabilité du produit:

Type de matériau | Barrière d'oxygène | Protection contre la lumière | Facteur de coût | |

|---|---|---|---|---|

Verre | Excellent | Pauvre | Meilleure stabilité | Modéré |

PET avec Amosorb | Très bien | Bien | Stabilité étendue | Plus haut |

PET standard | Équitable | Bien | Stabilité modérée | Inférieur |

Tubes en aluminium | Excellent | Excellent | Protection maximale | Le plus haut |

Choisir le bon emballage vous aide à contrôler les coûts et à répondre aux attentes des clients. Si vous souhaitez une durée de conservation plus longue, vous devrez peut-être payer plus pour de meilleurs matériaux.

Utilitaires et installations

Faire fonctionner une ligne de production de mayonnaise consomme beaucoup d’énergie et d’eau. Les vieilles machines et systèmes de refroidissement gaspillent de l’énergie et augmentent vos factures. La mise à niveau vers des systèmes économes en énergie coûte plus cher au début, mais vous économisez de l'argent avec le temps.

Technologie utilisée | Consommation d'énergie (MW) | |

|---|---|---|

Chaudière Électrique | 9 | N / A |

Pompe à chaleur | 2 | 75 |

Les coûts énergétiques représentent une grande partie de vos dépenses d’exploitation.

Améliorer l’efficacité énergétique peut vous faire économiser beaucoup d’argent.

Vous devriez chercher des moyens de réduire les coûts des services publics, comme utiliser des pompes à chaleur ou une meilleure isolation. Cela vous aide à maintenir vos coûts de production bas et à protéger vos bénéfices..

Réglementation et certification

Vous devez suivre les règles de sécurité alimentaire et obtenir les bonnes certifications pour vendre de la mayonnaise. Ces règles protègent vos clients et votre entreprise. Vous devrez peut-être payer pour les inspections, tests de laboratoire, et la paperasse. Si vous préparez de la mayonnaise biologique ou de spécialité, vous devez répondre à des normes supplémentaires.

Rester à jour avec la réglementation vous aide à éviter les amendes et les retards. Cela renforce également la confiance avec vos clients et ouvre de nouveaux marchés.. Vous devez inclure ces coûts dans votre budget lorsque vous envisagez de mettre en place une ligne de production de mayonnaise..

Conseil: Conservez des enregistrements de toutes vos certifications et inspections. Il est ainsi plus facile de les renouveler et de présenter un justificatif si nécessaire.

Comprendre chaque partie de la répartition de vos coûts vous aide à faire des choix intelligents. Vous pouvez contrôler vos dépenses, améliorer vos produits, et développez votre activité sur le marché de la mayonnaise.

Exemples de scénarios de coûts de ligne de production de mayonnaise

Quand vous envisagez de mettre en place une ligne de production de mayonnaise, vous devez savoir à quels coûts vous attendre. Vos coûts changeront en fonction de la taille de votre entreprise et de vos objectifs. Voici trois exemples pour vous aider à comprendre ce que les producteurs de mayonnaise pourraient dépenser à différentes étapes..

Exemple de coût de démarrage

Si vous voulez commencer petit, vous pouvez vous concentrer sur les besoins fondamentaux. Vous aurez besoin d'une simple machine à mayonnaise, un petit espace, et quelques ouvriers. Vos principaux coûts incluront le terrain, disposition de l'usine, machinerie, matières premières, conditionnement, transport, services publics, et le personnel. Voici un exemple de répartition:

Composant | Description | Considération des coûts |

|---|---|---|

Terrain et emplacement | Choisissez un petit site pour votre usine | Louer ou acheter |

Disposition de l'usine | Concevoir un simple, espace de travail sécurisé | Configuration de base |

Exigences en matière de machines | Acheter une petite machine à mayonnaise | Prix d'entrée de gamme |

Exigences en matières premières | Œufs, huile, vinaigre, et d'autres ingrédients | Acheter en petits lots |

Exigences d'emballage | Flacons ou pochettes simples | Commande minimum faible |

Exigences de transport | Options de livraison locale | Petit véhicule |

Exigences des utilitaires | Eau, électricité, gaz | Utilisation de base |

Exigences en matière de ressources humaines | Embaucher et former quelques travailleurs | Petite équipe |

Conseil: Commencez avec un petit lot pour tester le marché et ajuster votre production à mesure que la demande augmente.

Exemple de coût moyen

Si vous souhaitez augmenter votre production de mayonnaise, vous aurez besoin de machines plus avancées et d'une plus grande équipe. Une usine de taille moyenne peut produire environ 1,000 kg de mayonnaise par jour. Vous constaterez des coûts d’investissement et d’exploitation plus élevés, mais vous pouvez aussi gagner plus de profit. Voici un scénario typique:

Échelle des plantes | Investissement initial | Coût d'exploitation mensuel | Moy.. Bénéfice net mensuel | Marge bénéficiaire | Temps d’équilibre estimé |

|---|---|---|---|---|---|

20 à 35 millions ₹ | 5 à 8 000 ₹ | 4 à 7 000 ₹ | 35–45% | 7–12 mois |

Vous aurez besoin d'une machine à mayonnaise plus grande, meilleur emballage, et plus de personnel. Vous pouvez toucher plus de clients et répondre à une demande plus élevée du marché.

Exemple de coût à grande échelle

Si vous souhaitez devenir leader sur le marché de la mayonnaise, vous aurez besoin d'une grande installation et de machines de qualité supérieure. Vous utiliserez plusieurs machines à mayonnaise automatisées pour suivre les grosses commandes. Votre investissement sera bien plus élevé, mais on peut produire des milliers de kilos chaque jour. Vous aurez également besoin d'un emballage avancé et d'une équipe solide pour gérer la production et la qualité..

Vous pouvez approvisionner les supermarchés et les restaurants.

Vous pouvez recourir aux achats en gros pour réduire vos coûts de matières premières.

Vous pouvez investir dans le marketing pour développer votre marque.

Chaque étape a ses propres défis et récompenses. Vous devez choisir la bonne échelle pour vos objectifs et vos ressources. Une planification minutieuse vous aide à contrôler les coûts et à réussir votre production de mayonnaise.

Coûts opérationnels et rentabilité de la production de mayonnaise

Dépenses récurrentes

Vous ferez face à plusieurs dépenses récurrentes lorsque vous exploiterez une ligne de production de mayonnaise. Le coût le plus important vient souvent de l’achat de jaunes d’œufs. Les prix des œufs peuvent changer rapidement, ce qui rend difficile la planification de votre budget. De nombreux producteurs de mayonnaise utilisent des stabilisants et des émulsifiants pour contrôler ces coûts.. Ces ingrédients vous permettent d'utiliser moins d'œufs ou même de préparer une mayonnaise sans œufs.. Vous pouvez conserver la même texture et la même saveur tout en dépensant moins en matières premières. Cela vous aide à gérer vos coûts et à répondre à la demande du marché..

Calculer les marges bénéficiaires

Vous devez savoir combien de profit vous tirez de chaque pot de mayonnaise. Le calcul de votre marge bénéficiaire vous aide à fixer le bon prix et à voir si votre entreprise est saine. Voici quelques-uns façons courantes de déterminer votre marge bénéficiaire:

Description | Formule |

|---|---|

Marge bénéficiaire % | (Bénéfice brut / Prix de vente) × 100 |

Calcul de la marge bénéficiaire | ((Prix de vente – Prix de revient) / Prix de revient) × 100 |

Pourcentage de marge brute | (Revenu – Coût des marchandises vendues) / Revenu × 100 |

Vous devriez utiliser ces formules pour vérifier vos chiffres souvent. Cela vous aide à voir si votre machine à mayonnaise et vos autres coûts sont sous contrôle.. Si votre marge bénéficiaire baisse, vous pouvez chercher des moyens d'économiser de l'argent ou d'augmenter vos prix.

Contrôle qualité et rentabilité

Un contrôle qualité cohérent est essentiel pour contrôler le coût de la mayonnaise et satisfaire vos clients.. Vous devez vérifier la couleur de chaque lot, sécurité, et goûter. Voici quelques-uns étapes importantes du contrôle qualité:

Mesure de contrôle de qualité | Description |

|---|---|

Contrôle de la qualité des couleurs | Assure la cohérence des couleurs à l’aide de spectrophotomètres. |

Pasteurisation | Élimine les bactéries nocives, assurer la sécurité et prolonger la durée de conservation. |

Tests rigoureux | Teste chaque lot pour le pH, viscosité, et la saveur pour maintenir la qualité. |

Quand vous utilisez une machine à mayonnaise fiable, vous obtenez un mélange uniforme et de meilleurs résultats. Cela réduit les déchets et vous aide à économiser sur les ingrédients et les emballages.. Un bon contrôle qualité signifie également moins de retours et de plaintes, qui protège votre profit. Si vous souhaitez mettre en place une ligne de production de mayonnaise, se concentrer sur la qualité et l’efficacité pour garder une longueur d’avance sur les autres producteurs de mayonnaise.

Étapes pour mettre en place une ligne de production de mayonnaise et estimer les coûts

Liste de contrôle exploitable

Vous pouvez suivre ces étapes pour mettre en place une ligne de production de mayonnaise et estimer vos coûts:

Choisissez l'échelle de votre plante: Décidez si vous voulez un petit, milieu de gamme, ou installation entièrement automatique. Chaque échelle a des besoins d’investissement et un potentiel de profit différents.

Acheter des matières premières: Acheter de l'huile de haute qualité, œufs ou base sans œufs, vinaigre, et épices. Ces ingrédients affectent le goût et le coût de votre produit.

Sélectionnez les machines & Équipement: Investissez dans une machine à mayonnaise fiable, cuves de mélange, et réservoirs de stockage. Le bon équipement vous aide à travailler plus rapidement et à maintenir la cohérence de votre produit.

Planifier l'emballage & Étiquetage: Choisissez un emballage qui protège votre produit et attire les acheteurs. Assurez-vous que vos étiquettes respectent toutes les règles du marché.

Estimer les coûts de fonctionnement: Additionnez les dépenses mensuelles comme la main d'œuvre, services publics, et maintenance. Utilisez ces chiffres pour prédire votre seuil de rentabilité et vos bénéfices.

Suivre et ajuster: Utilisez un tableau simple pour comparer les échelles de plantes et voir laquelle correspond le mieux à vos objectifs.

Échelle des plantes | Investissement initial | Coût d'exploitation mensuel | Moy.. Bénéfice net mensuel | Marge bénéficiaire | Temps d’équilibre estimé |

|---|---|---|---|---|---|

À petite échelle (500 kg/jour) | 12 à 20 millions ₹ | 2 à 5 000 ₹ | 2 à 4 000 ₹ | 30–40% | 8–15 mois |

Moyenne échelle (1,000 kg/jour) | 20 à 35 millions ₹ | 5 à 8 000 ₹ | 4 à 7 000 ₹ | 35–45% | 7–12 mois |

Entièrement automatique (2,000+ kg/jour) | 40 000 ₹+ | 8 à 12 millions ₹ | 7 à 12 millions ₹ | 35–50% | 10–18 mois |

Conseil: Commencez avec une balance qui correspond à votre budget et à la demande du marché. Vous pouvez toujours vous développer à mesure que votre entreprise se développe.

Conseils d'optimisation des coûts

Vous pouvez améliorer votre retour sur investissement en utilisant des stratégies intelligentes. Voici quelques moyens éprouvés pour réduire les coûts et augmenter l’efficacité:

Stratégie | Avantages clés |

|---|---|

Principes de production Lean | Réduit les déchets et améliore la façon dont vous utilisez les ressources. |

Automatisation et robotique | Réduit les coûts de main-d’œuvre et accélère la production. |

Maintenance prédictive | Prévient les pannes et économise sur les réparations. |

Négociation et gestion des fournisseurs | Réduit les coûts des matières premières et maintient l’approvisionnement stable. |

Efficacité énergétique | Réduit les factures de services publics grâce à de meilleurs équipements et pratiques. |

Durabilité et réduction des déchets | Économise de l'argent en utilisant judicieusement les matériaux et en recyclant les déchets. |

Optimisation de la gestion des stocks | Maintient les niveaux de stock en équilibre et évite les pénuries ou les excès. |

Formation et développement des employés | Augmente la productivité et réduit le roulement du personnel. |

Digitalisation et analyse de données | Vous aide à repérer les tendances et à planifier les coûts futurs. |

Externalisation des activités non essentielles | Vous permet de vous concentrer sur ce que vous faites le mieux et de réduire les frais généraux. |

Note: Révisez souvent vos coûts. De petits changements dans votre processus peuvent conduire à de grosses économies au fil du temps.

Vous disposez désormais d’un chemin clair pour calculer les coûts de votre ligne de production de mayonnaise. Commencez par lister votre équipement, matériels, travail, conditionnement, et les besoins réglementaires. Utilisez les exemples et les listes de contrôle pour planifier votre configuration.

Examinez attentivement chaque domaine de coûts.

Ajustez votre plan à mesure que vous en apprenez davantage.

Suivez vos dépenses pour respecter votre budget.

Prêt à passer à l'étape suivante? Commencez votre analyse des coûts dès aujourd'hui ou contactez un expert du secteur pour obtenir des conseils.!

FAQ

Quel est le facteur le plus important pour contrôler les coûts de production de la mayonnaise?

Vous devez vous concentrer sur la répartition de vos coûts pour l'Inde. Suivez chaque dépense, des matières premières à l'emballage. Utilisez des machines à mayonnaise entièrement automatiques pour réduire les déchets et améliorer l’efficacité. Cela vous aide à garder votre processus simple et la qualité de vos produits élevée..

Comment l’échelle de production affecte-t-elle mon investissement?

Quand vous augmentez votre échelle de production, vous avez besoin d'un équipement plus avancé. Les machines à mayonnaise entièrement automatiques vous aident à répondre à la demande indienne croissante de pâtes à tartiner. Les opérations plus importantes réduisent souvent votre coût unitaire et améliorent la qualité de vos produits.

Pourquoi devrais-je me soucier de la qualité des produits dans la production de mayonnaise?

La qualité des produits renforce la confiance avec vos clients. Les spreads de haute qualité se démarquent sur le marché. Vous pouvez utiliser de meilleurs ingrédients et contrôler votre processus pour vous assurer que chaque lot répond aux normes de sécurité et de goût..

Quelles sont les principales étapes du processus de production de la mayonnaise?

Vous commencez par mélanger les œufs, huile, et du vinaigre. Alors, vous utilisez des mélangeurs à cisaillement élevé ou des machines à mayonnaise entièrement automatiques pour mélanger les ingrédients. Après cela, vous emballez les pâtes à tartiner et vérifiez la qualité des produits avant expédition.

Comment puis-je répondre à la demande indienne croissante de spreads?

Vous pouvez étendre votre ligne de production et investir dans des machines à mayonnaise entièrement automatiques. Ces machines vous aident à produire plus de tartinades rapidement. Se concentrer sur une gestion efficace des processus et maintenir une qualité de produit élevée pour répondre aux besoins du marché.

Jili88login Philippines… pour les Philippins par les Philippins? J'espère qu'ils proposent de bonnes promotions! Tara, célébrons notre argent durement gagné en, euh, tenter notre chance. Haha! Voici le lien: jili88loginphilippines

Yo, 56jlapp est pratique pour jouer sur mobile. Il est facile de s'y retrouver dans l'application et les jeux se chargent rapidement si votre connexion Internet est bonne. Ça vaut le détour: 56jlapp

Votre point de vue m'a interpellé et a été très intéressant. Merci. j'ai une question pour toi. https://accounts.binance.info/pl/register-person?ref=UM6SMJM3