Guanyu-mezclador emulsionante cosmético de alta viscosidad, loción corporal, tanque mezclador de crema, máquina emulsionante al vacío multifunción

Descripción de productos

Modelo | Capacidad efectiva | Emulsionar | Agitador | Dimensión exterior | El meritrado(kilovatios) | |||

kilovatios | rpm | kilovatios | rpm | Longitud*ancho*altura (milímetros) | Max H | |||

20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800*1600*1850 | 2700 | 5 |

50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700*2000*2015 | 2700 | 7 |

100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920*2120*2200 | 3000 | 10 |

150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110*2120*2200 | 3100 | 11 |

200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150*2200*2200 | 3100 | 12 |

350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650*2650*2550 | 3600 | 17 |

500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970*2800*2700 | 3950 | 19 |

750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780*3200*3050 | 4380 | 24 |

1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900*3400*3150 | 4550 | 29 |

1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000*4100*3750 | 5650 | 42 |

2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850*4300*3600 | / | 46 |

Introducción1. La máquina tiene triple licuadora, cubierta de elevación hidráulica, licuadora de homogeneidad de alta velocidad (La velocidad es 0-3500R/min, regulación de la velocidad de frecuencia) y licuadora de raspador de baja velocidad (La velocidad es 0-40R/min, regulación de la velocidad de frecuencia). La licuadora de emulsificación de vórtice de corte rápido se usa en la parte del homogeneizador, que puede raspar a baja velocidad y mezclar automáticamente y acurrucarse hasta el fondo y la pared de la caldera. La máquina dibuja material en polvo por vacío para evitar que el polvo vuele. Todo el procedimiento de trabajo se opera en la condición del vacío para evitar que el material se burbujee después de una mezcla de alta velocidad y alcance la solicitud de saneamiento y asepsis. El sistema de limpieza CIP está equipado en este sistema. La parte de contacto de la embarcación y el material está hecha de material SUS316L. El acabado espejo de la superficie interior es de 300emsh. Para garantizar la estabilización del control, La bomba de vacío es los productos de Alemania Siemens Company, El botón es producido por Japón Fujicompany, El transductor es el producto de Japan Matsushita Electric Industries y la parte de electro-Control es el producto de Siemens Company. La máquina se realiza completamente de acuerdo con la solicitud GMP, cuál es el equipo de producción de crema más avanzado y perfecto.2. La máquina está especialmente diseñada que adopta la tecnología avanzada del extranjero de acuerdo con la tecnología de producción cosmética y de ungüento. La máquina está compuesta de caldera de pretratamiento, caldera de mezcla de emulsión al vacío, bomba de vacío, sistema hidráulico y mesa de trabajo.3. La máquina tiene una operación fácil, capacidad estable, buena homogeneidad, alta eficiencia, estructura razonable, Volumen pequeño y alto nivel de automatización y limpia fácilmente. USAGEPT-THZRJ La licuadora de emulsionamiento de vacío está especialmente diseñada que adopta la tecnología avanzada del extranjero de acuerdo con la tecnología de producción cosmética y ungüenza. La máquina está compuesta de caldera de pretratamiento, caldera de mezcla de emulsión al vacío,bomba de vacío, sistema hidráulico y mesa de trabajo. Característica Esa unidad tiene características tales como operación simple, rendimiento estable, buena homogeneización, alta eficiencia de producción, limpieza conveniente, estructura razonable, espacio de piso pequeño, y alta automatización, etc..

paleta mezcladora

Regulación de velocidad de conversión de frecuencia 0-62r/min, La forma de las cuchillas se diseñará de acuerdo con sus materiales..

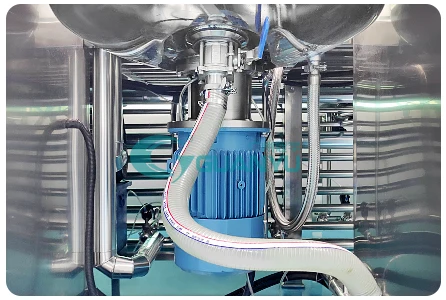

Homogeneizador

Regulación de velocidad de conversión de frecuencia 0-3000r/min, cabezal de corte homogéneo materiales de corte de alta velocidad, para que los materiales queden completamente rotos y mezclados!

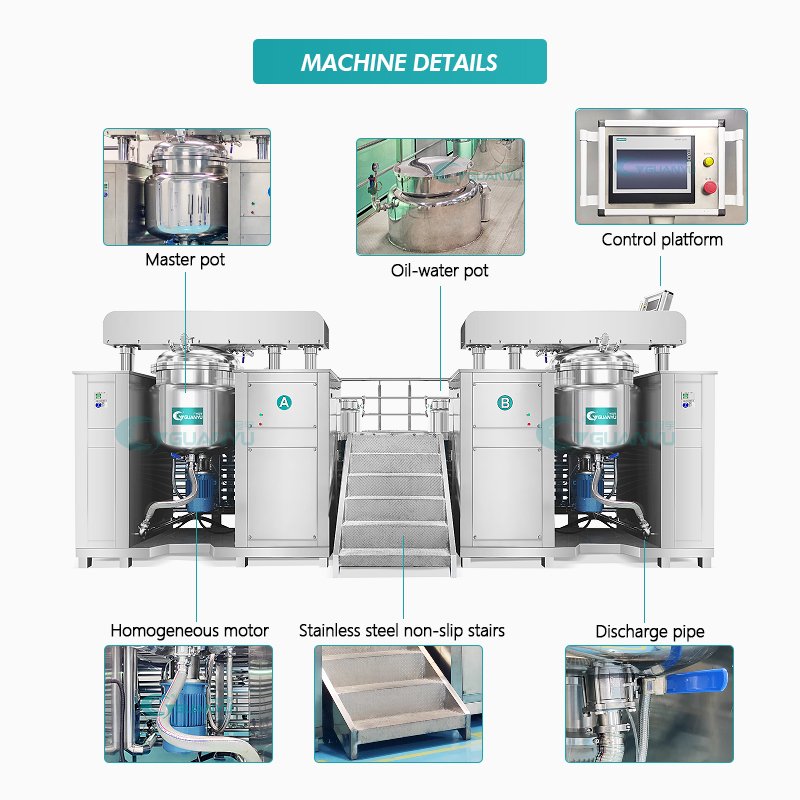

Olla de aceite y agua

Sistema de pretratamiento Recipiente de fase acuosa y fase oleosa para precalentar y dispersar las materias primas., luego transfiéralos a la olla principal para comenzar la producción..

Master pot

After pretreatment, the material is sucked into the main pot by vacuuming, and the material is emulsified by heating, emocionante, y homogeneización.

Consola

The PLC touch screen can automatically

control the discharge valve, the timing and

speed of homogenization/mixing,the heating

temperature of the pot, etc., and the function

switch of the equipment can be controlled

by a remote computer.

control the discharge valve, the timing and

speed of homogenization/mixing,the heating

temperature of the pot, etc., and the function

switch of the equipment can be controlled

by a remote computer.

caja electrica

Utilice una marca de renombre internacional.

componentes para garantizar la calidad del

Equipo y vida útil más larga.

componentes para garantizar la calidad del

Equipo y vida útil más larga.

Servicio

Diseñaremos dibujos según su

requisitos y proporcionar soluciones integrales.

requisitos y proporcionar soluciones integrales.

Configuración del producto

Sobre nosotros

Proceso de caso exitoso

Certificaciones

Preguntas más frecuentes

Reseñas

Aún no hay reseñas.