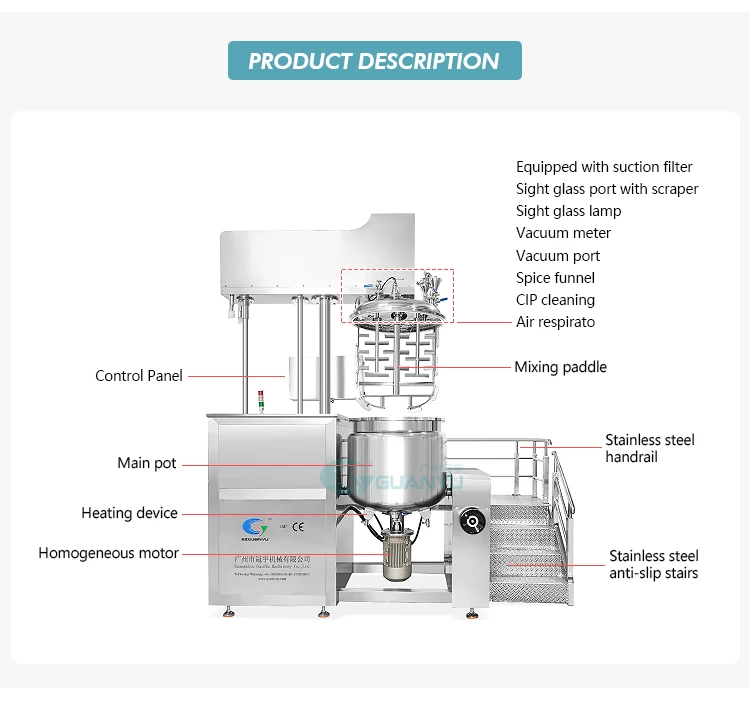

300l Agitator Homogenizer Vacuum Emulsifying Machine Mixer Body Lotion Cosmetic Cream Mixing Tank

Descripción de productos

Modelo | Capacidad efectiva | Emulsionar | Agitador | Dimensión exterior | El meritrado(kilovatios) | |||

kilovatios | rpm | kilovatios | rpm | Longitud*ancho*altura (milímetros) | Max H | |||

20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800*1600*1850 | 2700 | 5 |

50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700*2000*2015 | 2700 | 7 |

100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920*2120*2200 | 3000 | 10 |

150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110*2120*2200 | 3100 | 11 |

200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150*2200*2200 | 3100 | 12 |

350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650*2650*2550 | 3600 | 17 |

500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970*2800*2700 | 3950 | 19 |

750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780*3200*3050 | 4380 | 24 |

1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900*3400*3150 | 4550 | 29 |

1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000*4100*3750 | 5650 | 42 |

2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850*4300*3600 | / | 46 |

Introducción1. La máquina tiene triple licuadora, cubierta de elevación hidráulica, licuadora de homogeneidad de alta velocidad (La velocidad es 0-3500R/min, regulación de la velocidad de frecuencia) y licuadora de raspador de baja velocidad (La velocidad es 0-40R/min, regulación de la velocidad de frecuencia). La licuadora de emulsificación de vórtice de corte rápido se usa en la parte del homogeneizador, que puede raspar a baja velocidad y mezclar automáticamente y acurrucarse hasta el fondo y la pared de la caldera. La máquina dibuja material en polvo por vacío para evitar que el polvo vuele. Todo el procedimiento de trabajo se opera en la condición del vacío para evitar que el material se burbujee después de una mezcla de alta velocidad y alcance la solicitud de saneamiento y asepsis. El sistema de limpieza CIP está equipado en este sistema. La parte de contacto de la embarcación y el material está hecha de material SUS316L. El acabado espejo de la superficie interior es de 300emsh. Para garantizar la estabilización del control, La bomba de vacío es los productos de Alemania Siemens Company, El botón es producido por Japón Fujicompany, El transductor es el producto de Japan Matsushita Electric Industries y la parte de electro-Control es el producto de Siemens Company. La máquina se realiza completamente de acuerdo con la solicitud GMP, cuál es el equipo de producción de crema más avanzado y perfecto.2. La máquina está especialmente diseñada que adopta la tecnología avanzada del extranjero de acuerdo con la tecnología de producción cosmética y de ungüento. La máquina está compuesta de caldera de pretratamiento, caldera de mezcla de emulsión al vacío, bomba de vacío, sistema hidráulico y mesa de trabajo.3. La máquina tiene una operación fácil, capacidad estable, buena homogeneidad, alta eficiencia, estructura razonable, Volumen pequeño y alto nivel de automatización y limpia fácilmente. USAGEPT-THZRJ La licuadora de emulsionamiento de vacío está especialmente diseñada que adopta la tecnología avanzada del extranjero de acuerdo con la tecnología de producción cosmética y ungüenza. La máquina está compuesta de caldera de pretratamiento, caldera de mezcla de emulsión al vacío,bomba de vacío, sistema hidráulico y mesa de trabajo. Característica Esa unidad tiene características tales como operación simple, rendimiento estable, buena homogeneización, alta eficiencia de producción, limpieza conveniente, estructura razonable, espacio de piso pequeño, y alta automatización, etc..

paleta mezcladora

La regulación de velocidad de frecuencia variable es de 0-62 r/min., para que diferentes materiales se puedan mezclar uniformemente. La forma de la paleta mezcladora se diseñará de acuerdo con sus materiales.

Homogeneizador

Regulación de velocidad de conversión de frecuencia 0-3200r/min, cabezal de corte homogéneo materiales de corte de alta velocidad, para que los materiales queden completamente rotos y mezclados!

Accesorios

Materiales SS316, espesor 6 milímetros,Equipado con filtro de succión, válvula de drenaje, puerto de vacío, lámpara de mirilla, Puerto de mirilla con raspador, embudo de especias, limpieza cip, respirador de aire

Olla de aceite y agua

El tanque de fase acuosa y el tanque de fase oleosa del sistema de pretratamiento precalientan y dispersan las materias primas., luego transferirlos al tanque principal, y comenzar a mezclar homogéneamente para emulsionar los materiales.

Consola

La caja de control incluye ajustes como corte homogéneo, mezcla de regulación de velocidad de conversión de frecuencia,

tiempo de trabajo, extracción al vacío, calentamiento entre capas, etc..

tiempo de trabajo, extracción al vacío, calentamiento entre capas, etc..

Consola

Diseñaremos dibujos de acuerdo con sus requisitos y proporcionaremos soluciones únicas..

Configuración del producto

Sobre nosotros

Proceso de caso exitoso

Certificaciones

Preguntas más frecuentes

Ivy –

Oye! I’m at work browsing your blog from my new iphone

3gs! Just wanted to say I love reading your blog

and look forward to all your posts! Keep up the superb work!!

Norma –

Hola! ¿Sabes si hacen algún complemento para

ayuda con SEO? Estoy tratando de hacer que mi sitio se clasifique para

Algunas palabras clave específicas, pero no estoy viendo muy buenos resultados.

Si sabe de alguna. Gracias! Vi un artículo similar aquí: Mantas calientes