La elección del mezclador industrial adecuado para su planta comienza con una comprensión clara de sus necesidades de mezclado.. El mezclador correcto puede duplicar la eficiencia de su planta, como lo demuestran los estudios de caso que muestran encima 100% mejora en salida por lotes. Centrarse en la compatibilidad de materiales, capacidad, y requisitos del proceso desde el principio. Cuando elige sistemas mezcladores industriales, considerar no sólo las características técnicas sino también cómo materiales de construcción, instalación, y mantenimiento afectan la seguridad y los costos a largo plazo. El equipo de mezcla inteligente reduce el uso de energía y respalda la seguridad, operación confiable.

Control de llave

Elija un mezclador que combine con los materiales de su planta, tamaño del lote, y los procesos necesitan aumentar la eficiencia y la seguridad.

Comprender los diferentes tipos de mezcladores: mecánicos, estático, alto cizallamiento, y especialidad, para encontrar la mejor opción para su aplicación.

Considere la potencia del motor, materiales de construcción, control de velocidad, y facilidad de limpieza para garantizar mezcladores confiables y fáciles de mantener.

Equilibre el costo inicial con los gastos operativos y de mantenimiento para obtener valor a largo plazo y reducir el tiempo de inactividad..

Personalice y pruebe los mezcladores antes de comprarlos, y garantice la compatibilidad con el equipo y el espacio de su planta para una integración fluida.

Necesidades de mezcla de plantas

Compatibilidad de material

Debes comenzar por comprender los materiales que planeas mezclar en tu planta.. El tipo de liquido, polvo, estiércol líquido, o sustancia viscosa que utilice determinará el mejor mezclador industrial para su aplicación.. Por ejemplo, Las operaciones de las plantas mezcladoras de concreto a menudo involucran agua., cemento, arena, y aditivos. Cada material tiene propiedades únicas, como el tamaño de las partículas., contenido de humedad, y viscosidad. Estos factores afectan cómo funciona el proceso de mezcla y qué tan bien la batidora mezcla los ingredientes..

La compatibilidad química es crítica. Debería consultar tablas y bases de datos de compatibilidad química para comprobar cómo interactúan diferentes líquidos y sólidos. Estas guías le ayudan a evitar reacciones peligrosas y daños al equipo.. Las mejores prácticas incluyen:

Utilice tablas de compatibilidad de fuentes confiables para evaluar cómo funcionan juntos los aceites base y los espesantes.

Realizar pruebas de laboratorio como pruebas de solubilidad., características de formación de espuma, y pruebas de desgaste para comprobar cómo se comportan los materiales durante la mezcla.

Realice pruebas puntuales rápidas en el campo para ver si los líquidos se separan o espesan inesperadamente..

Para grasas y lubricantes, Utilice pruebas de punto de caída y de penetración para confirmar la compatibilidad..

Consejo: Separe siempre los productos químicos incompatibles y siga los protocolos de seguridad en su planta mezcladora de concreto.. Este paso protege su equipo y garantiza una mezcla segura..

Tamaño y capacidad del lote

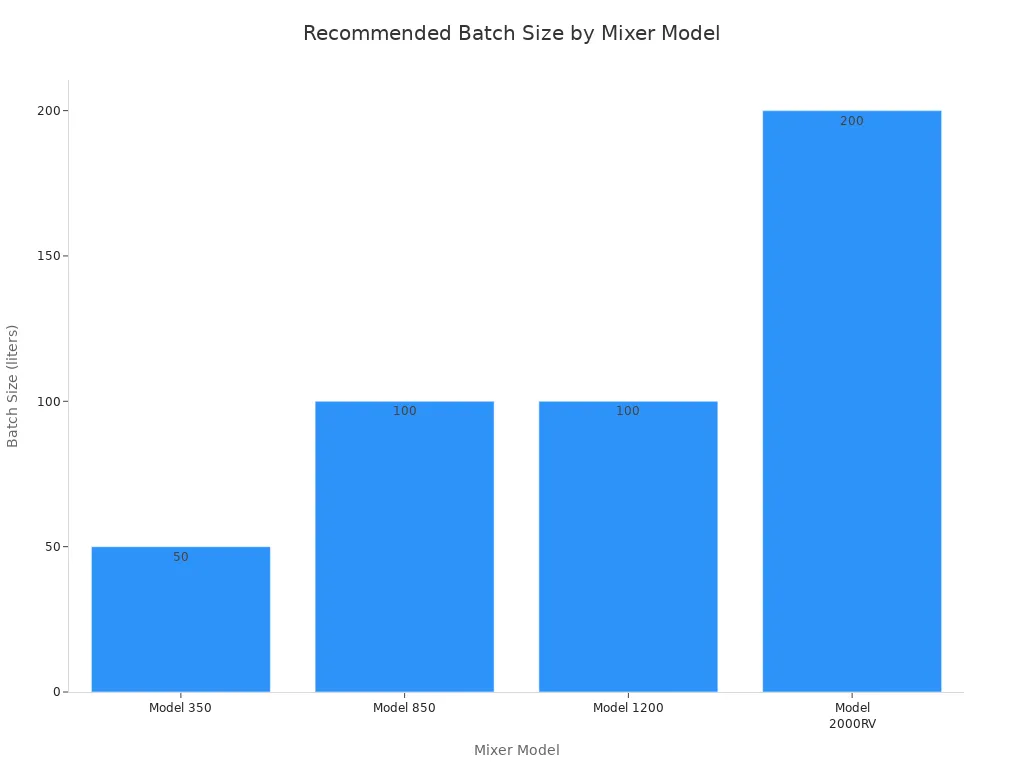

Necesita hacer coincidir la capacidad de su mezcladora con los objetivos de producción de su planta.. El tamaño del lote depende del tipo de mezclador y del volumen de líquido u hormigón que necesita procesar.. En una planta dosificadora de hormigón, Es posible que necesite mezclar grandes volúmenes rápidamente para satisfacer la demanda.. Para mezcladores de líquidos, El tamaño de lote recomendado varía según el modelo y la aplicación..

Aquí hay una tabla que muestra Tamaños de lote típicos para diferentes modelos de mezcladores.:

Modelo mezclador | Tamaño de lote recomendado (litros) | Características clave |

|---|---|---|

Modelo 350 | Arriba a 50 | Alto par, 350 Rpm, bajo consumo de energía |

Modelo 850 | Arriba a 100 | Torque moderado, 1000 Rpm, eficiente para lotes medianos |

Modelo 1200 | Arriba a 100 | Alta velocidad, Adecuado para mezcla rápida de líquidos. |

Modelo 2000RV | Arriba a 200 | Gran capacidad, Ideal para mezcladores de hormigón y líquidos de gran volumen. |

Cuando elige equipos mezcladores industriales, considere sus requisitos de capacidad. Si su planta necesita producir hormigón en grandes lotes, seleccione un mezclador que pueda manejar la carga sin ralentizar el proceso de mezcla. Para operaciones más pequeñas, un mezclador de líquidos compacto puede ser más eficiente.

Requisitos del proceso

El proceso de mezcla en tu planta depende de varios factores. Debes considerar el tiempo de mezcla., control de temperatura, y el tipo de fuente de energía disponible. Por ejemplo, La mezcla de concreto a menudo requiere una sincronización precisa para lograr la consistencia adecuada.. Es posible que los mezcladores de líquidos deban operar en tanques con camisa para mantener o ajustar la temperatura del producto..

Los mezcladores con tanques encamisados le ayudan a controlar la temperatura mediante la circulación de medios de calefacción o refrigeración. Esta característica es importante tanto para la mezcla de concreto como de líquidos..

La fuente de energía importa. Los mezcladores de aire comprimido funcionan bien en entornos con riesgos eléctricos., como plantas que manipulan líquidos inflamables. Los mezcladores monofásicos se adaptan a operaciones a pequeña escala, mientras que los mezcladores trifásicos son mejores para trabajos pesados, Mezclado continuo en grandes plantas mezcladoras de hormigón..

Su objetivo de mezcla: mezclar, partículas en suspensión, o emulsionar—determina la velocidad y el nivel de corte que necesita. Las condiciones de alta temperatura y presión requieren mezcladores con sellos y materiales especiales para mantener el proceso seguro..

Debes equilibrar potencia y velocidad para lograr la intensidad de mezcla deseada.. Demasiada energía puede desperdiciar energía o dañar su batidora. Muy poca potencia puede resultar en una mezcla deficiente y lotes de concreto o líquidos inconsistentes..

Nota: Siempre haga coincidir las características de su mezclador con los requisitos del proceso de su planta.. Este paso garantiza un funcionamiento eficiente y resultados de alta calidad en cada ciclo de mezcla..

Tipos de mezcladores industriales

Mezcladores Mecánicos

Los mezcladores mecánicos utilizan impulsores para agitar. concreto, líquido, o polvo dentro de tanques verticales. Encontrarás estos mezcladores en alimento, productos farmaceuticos, químico, plástica, tintas, pintura, revestimiento, comida para mascotas, salud animal, e industrias de tratamiento de aguas residuales. Mezcladores mecánicos suspenden partículas sólidas, mezclar líquidos miscibles, dispersar gases, y promover la transferencia de calor. puedes elegir mezcladores de tanque para diferentes volúmenes de lotes y viscosidades. Los mezcladores sanitarios cumplen estrictos estándares de higiene para productos farmacéuticos y alimentarios.. Los mezcladores de asas IBC funcionan bien para mezclar líquidos portátiles. Las mezcladoras de tambor y cubeta se adaptan a trabajos más pequeños y ofrecen modelos eléctricos o neumáticos.. Las personalizaciones incluyen sellos mecánicos y materiales de construcción para necesidades específicas de la planta mezcladora de concreto..

Consejo: Las mezcladoras mecánicas ofrecen versatilidad y rentabilidad para el hormigón, líquido, y mezcla de polvos en muchas aplicaciones industriales.

Mezcladores estáticos

Mezcladores estáticos mezclan hormigón, líquido, o gas sin partes móviles. Estos mezcladores se instalan directamente en tuberías para una mezcla continua.. Su tamaño compacto permite una fácil integración en los sistemas de plantas mezcladoras de concreto.. Los mezcladores estáticos entregan excelente eficiencia energética porque no necesitan energía externa. Usted se beneficia de un mantenimiento mínimo y una alta confiabilidad. Estos mezcladores funcionan mejor para mezcladores de líquidos en el tratamiento de agua., químico, alimento, y farmacéuticos. Sin embargo, Es posible que los mezcladores estáticos no manejen bien los polvos o sólidos y pueden mostrar una menor eficiencia de mezcla con diferentes viscosidades..

Aspecto | Mezcladores estáticos | Mezcladores dinámicos |

|---|---|---|

Costo | Bajo costo | Mayor costo debido a piezas móviles y diseño complejo |

Consumo de energía | No se requiere alimentación externa, eficiencia energética | Requiere energía eléctrica para su funcionamiento. |

Partes móviles | Ninguno, lo que lleva a un mantenimiento mínimo y una alta confiabilidad | Tiene partes móviles (ejes giratorios, impulsores), requiriendo mantenimiento |

Huella | Huella pequeña, fácil de instalar | Huella más grande, se requiere más espacio |

Eficiencia de mezcla | Potencialmente menor eficiencia de mezcla, especialmente con viscosidades variables | Eficiencia de mezcla superior, Capaz de alto cizallamiento y mezcla completa. |

Materiales adecuados | Fluidos y gases; no apto para polvos o sólidos que puedan obstruir el mezclador | Puede mezclar polvos, sólidos, y materiales de alta viscosidad |

Mantenimiento | Mantenimiento mínimo debido a que no hay piezas móviles. | Requiere mantenimiento regular debido a los componentes mecánicos. |

Tipo de aplicación | Ideal para mezcla continua en línea | Adecuado para mezclas por lotes y aplicaciones exigentes |

Fiabilidad | Alta confiabilidad gracias a un diseño simple y sin puntos de falla mecánica | Sujeto a fallo mecánico debido a piezas móviles. |

Mezcladores de alto cizallamiento

Los mezcladores de alto cizallamiento destacan en la emulsificación, homogeneización, dispersión, y moler. Utilice estos mezcladores cuando necesite disolver componentes inmiscibles o difíciles de mezclar en concreto., líquido, o polvo. Los mezcladores de alto cizallamiento procesan fluidos con viscosidades de 1 a 10,000 CPS, incluyendo fluidos tixotrópicos y adelgazantes. Puede lograr una dispersión uniforme y evitar la formación de grumos en la mezcla de polvo y líquido.. Estos mezcladores se adaptan a formulaciones de alta viscosidad., reducción del tamaño de partículas, y emulsiones estables. Los mezcladores discontinuos de alto cizallamiento funcionan para grandes volúmenes en operaciones de plantas mezcladoras de concreto. Los mezcladores de alto cizallamiento en línea proporcionan una mezcla continua con un control preciso para productos farmacéuticos, alimento, y productos químicos especiales.

Elija mezcladoras de alto cizallamiento para hormigón, líquido, y mezcla de polvo cuando necesita fuerzas de corte intensas y un control preciso sobre el tamaño de las partículas.

Mezcladores especiales

Mezcladores especiales abordar aplicaciones industriales únicas en plantas mezcladoras de concreto, alimento, productos farmaceuticos, e industrias químicas. Las mezcladoras de tambor utilizan tambores giratorios con palas interiores para pinturas., revestimiento, y productos químicos especiales. Los mezcladores continuos cuentan con alimentadores automatizados y transportadores de tornillo para una mezcla ininterrumpida de concreto y líquidos.. Los mezcladores acústicos utilizan la resonancia para una mezcla rápida en la fabricación de productos farmacéuticos y alimentos especiales.. Los mezcladores de fluidización utilizan turbulencia para mezclar polvos para productos químicos y piensos agrícolas.. Mezcladores convectivos, como batidoras de cinta y batidoras de paletas, Proporcionar una mezcla robusta para los alimentos., productos farmaceuticos, cemento, y fertilizante. Las amasadoras y las amasadoras de espiral se encargan de la panadería y el procesamiento de alimentos. Los mezcladores al vacío funcionan por debajo de la presión atmosférica para dispositivos médicos y adhesivos..

Tipo de mezclador | Características distintivas y aplicaciones industriales |

|---|---|

Mezcladores de tambor | Tambores giratorios; portátil o estacionario; control de dosificación; minimizar la contaminación; utilizado en pinturas, revestimiento, construcción, productos químicos especiales. |

Mezcladores continuos | Alimentadores automatizados; entrada/descarga constante; utilizado en concreto, procesamiento de minerales, extrusión de alimentos. |

Mezcladores acústicos | resonancia acústica; mezcla rapida; sin partes móviles; ideal para productos farmacéuticos, comida especial. |

Mezcladores de fluidización | Turbulencia de alta velocidad; mezclar polvos; utilizado para productos químicos, detergentes, polvos nutricionales, alimenta. |

Mezcladores convectivos | Impulsores/paletas; mezcla rápida; adecuado para la comida, productos farmaceuticos, cemento, fertilizante. |

Mezcladoras de masa | Amasar/airear la masa; velocidad variable; utilizado en panadería, procesamiento de alimentos. |

Mezcladores al vacío | Mezclar al vacío; prevenir la formación de espuma; utilizado en dispositivos médicos, adhesivos, compuestos. |

Nota: Los mezcladores especiales ofrecen soluciones personalizadas para hormigón, líquido, y mezcla de polvos en aplicaciones industriales exigentes.

Características del mezclador

Potencia y eficiencia

Debe seleccionar la potencia del motor en función de la viscosidad de los materiales que planea mezclar.. La viscosidad mide cuánto resiste un líquido al movimiento cuando se le aplica energía.. Si trabaja con líquidos de baja viscosidad, como agua o productos químicos ligeros, necesitas menos potencia del motor. Materiales de alta viscosidad, como hormigón espeso o lodos pesados, requieren más caballos de fuerza para lograr una mezcla adecuada. Medición precisa de la viscosidad a la temperatura de funcionamiento le ayuda a evitar sobrecargas y fallos del motor.. La siguiente tabla muestra cómo el tipo de impulsor y la viscosidad afectan las necesidades de potencia del motor.:

Tipo de impulsor | Rango de viscosidad | Características de corte | Requisito de potencia del motor |

|---|---|---|---|

Hidroala | Baja viscosidad | agitación suave, bajo cizallamiento | Se necesitan los caballos de fuerza más bajos |

Hélice marina | Baja viscosidad | Corte ligeramente mayor | Potencia ligeramente mayor que el hidroala |

Turbina de flujo axial | Mayor viscosidad | Alto cizallamiento, empuja fluidos viscosos | Requiere mayor potencia para conducir |

Turbina de flujo radial | Variable, a menudo para dispersión de gas o recipientes poco profundos | Produce flujo perpendicular al eje. | La potencia depende de la aplicación., a menudo más alto debido al patrón de flujo |

Hacer coincidir la potencia del motor con la viscosidad del material garantiza una mezcla eficiente tanto para mezcladores de líquidos como para aplicaciones de hormigón..

Materiales de construcción

Compatibilidad de materiales Es esencial para la durabilidad y seguridad en mezcladores industriales.. Debes elegir materiales de construcción que resistan la corrosión y el ataque químico.. El acero inoxidable funciona bien para mezcladores de líquidos y mezclas de concreto porque previene la contaminación y mejora la calidad del producto.. El diseño del mezclador también afecta los costos de mantenimiento y reparación.. Considere estos factores:

Los mezcladores industriales están diseñados para un uso prolongado, pero El mantenimiento afecta la durabilidad..

Las hojas soldadas se limpian fácilmente pero no se pueden reemplazar. Las hojas atornilladas se pueden cambiar para soportar el desgaste abrasivo.

Los sellos y juntas previenen la contaminación y el desgaste.. Los sellos reemplazables reducen el tiempo de inactividad y mantienen la calidad del producto.

El suministro de aire adecuado a los sellos evita el desgaste prematuro o fallas..

La elección de materiales y la personalización del diseño influyen en las necesidades de mantenimiento y la confiabilidad..

Seleccionar los materiales adecuados protege su mezcladora y los productos que procesa.

Velocidad y control

Las funciones de velocidad y control le brindan flexibilidad al mezclar. Variadores de frecuencia (VFD) Le permite ajustar las velocidades de mezcla en tiempo real.. Puedes iniciar las batidoras suavemente, proteger el equipo de picos de torsión. El ajuste de la velocidad le permite ajustar la energía de corte para mezclar líquidos, mezclar concreto, o manipulación de materiales frágiles. Los operadores pueden hacer funcionar los agitadores a diferentes velocidades durante la descarga., mejorar el flujo de productos y el cambio. El control de velocidad también ayuda a minimizar el desgaste mecánico y prolonga la vida útil del equipo.. Por ejemplo, un fabricante mejoró la calidad del producto y tiempo de licuado reducido mediante 76% usando una licuadora de cinta de velocidad variable.

Capacidad de limpieza

La facilidad de limpieza mantiene su batidora segura y eficiente. Debería Desarme los mezcladores periódicamente para una limpieza profunda.. Evite las grietas donde se puedan acumular contaminantes.. La lubricación regular y la inspección de las piezas móviles evitan averías. Lavadores de tanques automatizados y limpieza in situ (Titubear) sistemas Reducir la exposición de los trabajadores a productos químicos peligrosos y garantizar una limpieza exhaustiva.. Diseños sin retención y válvulas de descarga compensadas. minimizar los residuos del producto. Los mezcladores verticales permiten un fácil acceso para la limpieza., mientras que las mezcladoras de paletas horizontales pueden necesitar la intervención del operador. Estas características respaldan la higiene y reducen el tiempo de inactividad en mezcladoras de líquidos y mezcladoras de concreto..

Seguridad

Las características de seguridad protegen a los operadores y cumplen con los estándares regulatorios.. Las mezcladoras deben tener cubiertas o recintos con Dispositivos de enclavamiento que impiden el funcionamiento a menos que la cubierta esté en su lugar.. Los mezcladores horizontales con puertas de descarga requieren controles con dos manos cuando las puertas están abiertas. Las batidoras verticales necesitan dispositivos de bloqueo positivo de los tazones y ayudas para mover tazones pesados.. Las batidoras verticales grandes deben tener protectores de tazón entrelazados para evitar la aplicación de energía a menos que las cubiertas y los tazones estén en su lugar correctamente.. Estos controles mantienen su proceso de mezcla seguro tanto para aplicaciones líquidas como de concreto..

Costo y valor

Costo inicial

Cuando eliges una batidora industrial, debes considerar el costo inicial. Esto incluye el precio de la batidora., instalación, y cualquier accesorio requerido. Las batidoras de alta calidad suelen costar más por adelantado, pero ofrecen mejor rendimiento y confiabilidad. Debes comparar modelos según las características., materiales de construcción, y capacidad. Los mezcladores con controles avanzados u opciones personalizadas pueden aumentar su inversión inicial. Una tabla simple puede ayudarle a comparar costos:

Tipo de mezclador | Rango de precios base | Costo de instalación | Costo de funciones personalizadas |

|---|---|---|---|

Mezclador mecánico | $5,000–$20,000 | $2,000–$5,000 | $1,000- $ 10,000 |

Mezclador estático | $2,000–$8.000 | $1,000–$3.000 | $500–$5,000 |

Mezclador de alto cizallamiento | $10,000–$40.000 | $3,000–$8.000 | $2,000–$15,000 |

Consejo: Invertir en un mezclador duradero reduce los costos de reemplazo y respalda la eficiencia de la planta a largo plazo.

Costos operativos

Los costos operativos incluyen el uso de energía., mano de obra, y suministros de rutina. Las batidoras con motores eficientes y controles de velocidad le ayudan a reducir las facturas de electricidad. Los mezcladores automatizados reducen el trabajo manual y mejoran la seguridad. Debes controlar el consumo de energía., especialmente si utiliza mezcladores durante períodos prolongados. Las mezcladoras con filtros obstruidos o componentes desgastados consumen más energía y pueden ralentizar la producción.. Las comprobaciones periódicas y las actualizaciones oportunas mantienen bajos sus costos operativos.

Los mezcladores eficientes ahorran dinero en energía.

La automatización reduce el error humano y los costos laborales.

Las inspecciones de rutina evitan gastos inesperados.

Mantenimiento y tiempo de inactividad

El mantenimiento y el tiempo de inactividad afectan la productividad y las ganancias de su planta. Debes estar atento a desgaste de los sellos, juntas, cuchillas, aspectos, e interruptores de seguridad. El polvo y las fugas de los sellos desgastados pueden causar contaminación y riesgos de seguridad.. El desgaste de las cuchillas reduce la efectividad de la mezcla y aumenta los tiempos de mezcla. Fugas en el sistema hidráulico, conexiones sueltas, y sobrepresurización A menudo conducen a fallas en los componentes.. Desgaste de la caja de cambios, fugas en el tanque, y el sobrecalentamiento del motor también perturban las operaciones.

Las causas comunes del tiempo de inactividad incluyen:

Sellos o juntas desgastados que provocan fugas de líquido.

El desgaste de las cuchillas afecta la consistencia del lote

Sobrecalentamiento del motor debido a piezas defectuosas o mala lubricación

Desgaste de los rodamientos que provoca vibraciones y ruidos.

Desalineación y variación de velocidad debido a controladores defectuosos

Mantenimiento regular y renovación oportuna., como reemplazar piezas desgastadas o actualizar controles, Le ayuda a evitar costosos tiempos de inactividad y a mantener su mezclador funcionando sin problemas..

Personalización y pruebas

Opciones personalizadas

Puede personalizar los mezcladores industriales para que se ajusten a las necesidades únicas de su planta.. Los fabricantes ofrecen una amplia gama de funciones de personalización.. Tu seleccionas el tamaño que coincida con los requisitos de su lote. Eliges materiales de construcción que resistan la corrosión o manejen sustancias abrasivas. Las opciones de instalación le permiten colocar mezcladores en espacios reducidos o montarlos de diferentes maneras..

Sistemas de detección de fugas ayudarle a detectar problemas a tiempo y proteger su producto.

Los arreglos de sellos mecánicos mantienen su mezclador funcionando sin problemas y evitan la contaminación..

El montaje en ángulo fijo o variable le permite ajustar la batidora para mezclar mejor.

Las disposiciones de transmisión por correa o caja de cambios le brindan control sobre la velocidad y el torque.

Las configuraciones de montaje, como las opciones con tirante o con patas, facilitan la instalación.

Instalación en sitio, solución de problemas, y el soporte de mantenimiento preventivo mantienen su equipo funcionando de manera confiable.

Obtienes flexibilidad al seleccionar estas opciones. Mejoras la seguridad, eficiencia, y calidad del producto en su planta.

Consejo: Personalizar su mezclador garantiza que cumpla con los requisitos de su proceso y se adapte a futuros cambios en la producción..

Pruebas de laboratorio

pruebas de laboratorio juega un papel clave antes de ampliar las operaciones del mezclador. Valida el rendimiento y detecta los problemas a tiempo. Utiliza las mismas materias primas y proporciones tanto en la fase de laboratorio como en la de producción.. Esta práctica le ayuda a mantener una calidad constante..

Aspecto | Explicación |

|---|---|

Pruebas de funcionalidad | Las pruebas de laboratorio garantizan que el mezclador cumpla con los requisitos funcionales específicos antes de ampliarlo.. |

Sintonia FINA | Lab permite ajustes iterativos a los prototipos para corregir errores y optimizar el rendimiento.. |

Cumplimiento de estándares | Los datos de las pruebas de laboratorio ayudan a garantizar que el producto cumpla con los estándares de la industria en cuanto a rendimiento y seguridad.. |

Materias primas idénticas | El uso de las mismas materias primas y proporciones en las fases de laboratorio y producción garantiza una calidad y resultados consistentes.. |

Mismo uso de maquinaria | Emplear el mismo tipo de mezclador en el laboratorio., piloto, y la producción evita discrepancias causadas por el cambio de equipo.. |

Continuidad del personal | Involucrar al personal de laboratorio en la producción ayuda a transferir conocimientos y mantener la integridad del proceso.. |

Modelos de equipos de Hockmeyer | Disponibilidad de laboratorio, piloto, y los modelos de producción garantizan uniformidad y coherencia durante todo el proceso de ampliación.. |

Sigues un proceso paso a paso para validar tu batidora:

Tú Prototipos de prueba y plantas piloto. para identificar problemas mecánicos y optimizar la mezcla.

Validas parámetros de proceso y selección de equipos en condiciones semiindustriales..

Aplica requisitos de similitud experimental para garantizar que los resultados de laboratorio coincidan con la producción a gran escala..

Utiliza modelos de dinámica de fluidos computacional y cinética química para predecir cambios en el rendimiento..

Las pruebas de laboratorio le brindan confianza en la confiabilidad de su mezclador y lo ayudan a evitar errores costosos durante el aumento de escala..

Producción de alimentos y bebidas

Necesidades de la industria alimentaria

Debes priorizar la higiene y la seguridad a la hora de seleccionar batidoras industriales para aplicaciones alimentarias. La producción de alimentos y bebidas exige equipos que prevengan la contaminación y faciliten la limpieza.. Debes elegir batidoras hechas de Acero inoxidable resistente a la corrosión y plásticos aptos para uso alimentario.. Estos materiales resisten la limpieza y desinfección repetidas., que es esencial para la alimentación, productos farmaceuticos, productos cosméticos, e instalaciones de tratamiento de aguas residuales.

Las mezcladoras industriales para el procesamiento de alimentos deben tener una superficie suave., superficies sin costuras. Las esquinas y grietas afiladas permiten que se acumulen partículas de alimentos y microorganismos., crecientes riesgos de contaminación. Necesita batidoras que permitan un fácil desmontaje de las palas., cuchillas, y cubiertas sin herramientas especiales. Este diseño admite una limpieza y un mantenimiento exhaustivos..

Las normas reglamentarias desempeñan un papel fundamental en la producción de alimentos. Debes cumplir con requisitos de organizaciones como la FDA., EFSA, y USDA. Ruedas de acero inoxidable ayudarle a cumplir con estos estándares al resistir la corrosión y respaldar la movilidad de equipos pesados. Sus superficies no porosas facilitan la limpieza y la higienización., lo cual es vital para mantener la higiene operativa.

Consejo: Los procedimientos de limpieza regulares incluyen la eliminación de residuos de alimentos., desmontaje de componentes, usando detergentes y desinfectantes aprobados, y secar antes de volver a montar. Estos pasos le ayudan a evitar la contaminación y garantizar el cumplimiento..

Necesidades de la industria de bebidas

Debe seleccionar mezcladores que cumplan estrictos requisitos higiénicos para el procesamiento de bebidas.. La industria de bebidas confía en certificaciones como la 3-A para garantizar la seguridad de los equipos. Empiece por identificar el estándar 3-A relevante para mezcladores.. Usted compra la documentación actual y prueba el diseño higiénico de su batidora., incluyendo limpieza en el lugar (Titubear) actuación. Las pruebas de residuos de riboflavina bajo luz ultravioleta confirman una limpieza eficaz.

Un evaluador de conformidad certificado revisa los resultados de sus pruebas y sus instalaciones de producción.. Una vez que pases, recibes el oficial 3-un certificado. Esta certificación le permite exhibir el símbolo 3-A, mostrando cumplimiento con los estándares de la industria. También deberías considerar ISO 9000 Certificación para la gestión de calidad en bebidas., productos farmaceuticos, productos cosméticos, y procesamiento químico.

La personalización agrega valor a su selección de mezcladores. Puede solicitar funciones que admitan aplicaciones de bebidas específicas, como sistemas de limpieza automatizados o sellos especializados. Estas opciones lo ayudan a cumplir con los estándares regulatorios y mejorar la eficiencia en el sector de bebidas., productos farmaceuticos, cosméticos y cuidado personal, y tratamiento de aguas residuales.

Integración de procesos

Compatibilidad del equipo

Debe asegurarse de que su mezclador industrial funcione a la perfección con otros equipos de su planta.. Zapatillas & Los equipos de proceso resaltan la importancia de personalización para compatibilidad de materiales, capacidad, y sistemas de control. Este enfoque le ayuda a lograr un rendimiento de mezcla óptimo y una integración fluida con los procesos existentes.. Al integrar mezcladores de líquidos, necesitas comprobar compatibilidad con el llenado automático, embalaje, calefacción, enfriamiento, transportadores, y sistemas de dosificación.

La compatibilidad del equipo mejora la eficiencia del flujo de trabajo y mantiene constante la calidad del producto..

La integración con sistemas automatizados de llenado y envasado permite un porcionado preciso y reduce el desperdicio..

La conexión con sistemas de calefacción y refrigeración garantiza el control de la temperatura., que es fundamental para la alimentación, farmacéutico, y tratamiento de aguas residuales.

La integración de mezcladores de líquidos con transportadores y equipos de procesamiento por lotes automatiza el manejo de materiales y mejora la escalabilidad..

La combinación de mezcladores con sistemas de dosificación respalda el cumplimiento normativo y reduce el desperdicio de materia prima.

La capacitación del personal y los protocolos de seguridad son esenciales para una operación segura y efectiva..

Los sistemas de monitoreo y ajuste lo ayudan a mantener un rendimiento de mezcla consistente.

Siempre debes considerar estos factores al incorporar el mezclador de líquidos a tu planta.

Espacio e instalación

Debe planificar el espacio y la instalación antes de integrar mezcladores de líquidos en sus instalaciones.. El tamaño de su batidora determina el espacio de piso, espacio libre, y espacio libre necesario para una operación y mantenimiento seguros. La siguiente tabla muestra los requisitos típicos para diferentes tamaños de mezcladores.:

Tamaño del mezclador | Tipo de instalación | Espacio requerido | Espacio libre requerido | Espacio libre alrededor del mezclador | Conexiones de servicios públicos | Notas sobre mantenimiento y expansión |

|---|---|---|---|---|---|---|

Mezclador de paletas de laboratorio pequeño | Mesa/mesa | Al menos 60 centímetros x 80 centímetro | N / A | Alguna autorización para operación y controles. | Fuente de agua cercana si es necesario; acceso al poder | Compacto, adecuado para espacio limitado |

Mezclador de paletas industrial mediano | Montado en el suelo | Aprox.. 3 mx 3 metro | 2 – 2.5 metros | 1 – 2 metros de liquidación | Fuerza, agua, conexiones de aire comprimido | Espacio para acceso de mantenimiento y movimiento de remo. |

Mezclador grande de doble paleta | Sala/área dedicada | 6 mx 6 m o más | 3 – 4 metros | 1 – 2 metros de liquidación | Fuerza, agua, aire comprimido, sistemas de alimentación | Requiere amplio espacio para su funcionamiento., mantenimiento, y futura expansión |

deberías irte 1-2 Metros de espacio libre alrededor de los mezcladores para un acceso seguro.. Asegúrese de que las conexiones de servicios públicos, como el poder, agua, y aire comprimido, son de fácil acceso y cumplen con los códigos locales. Planifique una expansión futura dejando espacio adicional para equipos de mezcla más grandes o adicionales..

Sistemas de control

Puedes elegir entre un Gama de sistemas de control para gestionar las operaciones de mezclado.. Las opciones incluyen interruptores de encendido/apagado simples y sistemas de recetas basados en PLC totalmente automatizados.. Estos sistemas están diseñados y programados para satisfacer sus necesidades específicas.. Los sistemas de control cubren procesos como la mezcla., mezcla, dispersión, el secado, cargando, descarga, y limpieza en el lugar (Titubear).

Los sistemas de control están certificados por UL y probados para un arranque confiable.

Puede automatizar el manejo de materiales con transportadores y alimentadores para una medición precisa de los ingredientes.

El software de gestión de recetas le permite almacenar y ajustar recetas de mezcla para obtener resultados consistentes.

Los sistemas de control de lotes automatizan la secuenciación de procesos y estandarizan los flujos de trabajo.

Sistemas de seguridad, como paradas de emergencia y alarmas, proteja a su personal.

Los programas de mantenimiento y capacitación del operador mantienen su sistema funcionando sin problemas.

El registro y análisis de datos lo ayudan a monitorear los parámetros clave y optimizar la mezcla..

La integración con sistemas ERP mejora la planificación de la producción y la gestión de inventario..

Las revisiones y actualizaciones periódicas garantizan que su automatización se mantenga actualizada.

Integrando mezcladores de líquidos con sistemas de control avanzados, Mejora la eficiencia y mantiene una alta calidad del producto en cada lote.. Este enfoque es compatible con una amplia gama de industrias., incluyendo comida, bebida, y procesamiento de aguas residuales.

Evitar errores

Errores comunes

Puede evitar errores costosos al elegir mezcladores industriales comprendiendo los errores más frecuentes. Muchos gerentes de planta seleccionan equipos más baratos sin considerar la eficiencia a largo plazo., mantenimiento, y costos de calidad del producto. Puede pasar por alto la necesidad de capacitar al personal, lo que puede provocar accidentes y una infrautilización del mezclador. Algunos operadores no optimizan los procesos de mezcla, perder oportunidades para mejorar los flujos de trabajo y la productividad.

Deberías estar atento a estos errores comunes:

Ignorar los protocolos de seguridad, especialmente cuando se manipulan materiales peligrosos como aditivos para hormigón.

No instalar sistemas de seguimiento y ajuste, lo que resulta en una mezcla inconsistente.

Mala integración con otras máquinas., como conexiones faltantes entre mezcladores y llenado, embalaje, o sistemas de dosificación.

Sin considerar la dedicación de línea, que afecta la limpieza y operación en líneas de producción de concreto multipropósito o dedicadas.

Pasar por alto los requisitos del sitio, incluyendo espacio y proximidad a otras máquinas.

Descuidando la durabilidad y la precisión, lo que afecta el mantenimiento y la calidad del producto..

Olvidarse de planificar cambios futuros en las formulaciones, tecnología, o crecimiento de la empresa.

No tener en cuenta la composición del material, procesos quimicos, comederos, y personalizaciones necesarias.

Pasar por alto los requisitos de saneamiento, especialmente en la comida, farmacéutico, y aplicaciones nutracéuticas.

Ignorar el control de temperatura y las características de seguridad, como camisas de refrigeración o componentes a prueba de explosiones en la mezcla de hormigón.

Consejo: Revise siempre las necesidades específicas de su planta y los planes futuros antes de seleccionar una mezcladora para concreto u otras aplicaciones..

Selección de proveedores

Debe elegir un proveedor confiable para garantizar que su mezclador funcione bien en operaciones de concreto y otras plantas.. Empezar por evaluar la reputación del proveedor en cuanto a productos de calidad y excelente servicio al cliente. Un soporte posventa confiable es esencial para minimizar el tiempo de inactividad y mantener la productividad..

Siga estos pasos para evaluar proveedores:

Comprobar la calidad de los materiales y componentes utilizados en sus mezcladores., especialmente para mezclar hormigón.

Verificar su proceso de fabricación y control de calidad en cada etapa..

Evaluar su compromiso con la atención al cliente durante la compra., instalación, y mantenimiento continuo.

Revisar los comentarios de los clientes, certificaciones de la industria, y premios.

Considere su experiencia, proyectos exitosos, y capacidad de adaptarse a las necesidades de su planta.

Examinar su gama de productos., capacidades técnicas, y disponibilidad de repuestos y servicios de mantenimiento..

Nota: Un proveedor confiable lo ayuda a evitar problemas inesperados y garantiza que su mezcladora cumpla con las demandas del concreto y otras aplicaciones industriales..

Cómo elegir un mezclador industrial

Comparar opciones

Debe comparar los mezcladores preseleccionados antes de tomar una decisión final.. Comience analizando los principales factores que afectan el rendimiento de la mezcla y la eficiencia de la planta.. Cada mezclador ofrece diferentes puntos fuertes., por lo que debe adaptarlos a sus necesidades de producción..

Capacidad y tamaño: Seleccione una batidora que se ajuste al volumen de su lote. Las batidoras de encimera pequeñas funcionan para tiradas limitadas. Los modelos industriales grandes se adaptan a mezclas de gran volumen.

Acción y tipo de mezcla: Las amasadoras de espiral manejan masas y mezclas espesas.. Los mezcladores planetarios funcionan bien para líquidos y polvos.. Elija la acción de mezcla que coincida con su producto.

Variabilidad de la potencia y la velocidad del motor: Potentes motores con velocidades ajustables te ayudan a mezclar diferentes recetas y materiales.. El control de velocidad le permite ajustar el proceso de mezcla.

Calidad de construcción y material: La construcción de acero inoxidable le brinda durabilidad e higiene.. Los materiales de alta calidad resisten la corrosión y el desgaste durante la mezcla..

Características de automatización: Los mezcladores automatizados con ajustes programables mejoran la eficiencia. Puede reducir la mano de obra y mantener resultados de mezcla consistentes.

Eficiencia y velocidad: La alta eficiencia es fundamental para la mezcla a gran escala. Los mezcladores rápidos le ayudan a mantenerse al día con las demandas de producción.

Necesidades de mantenimiento: El mantenimiento sencillo mantiene su batidora en funcionamiento. Las máquinas con diseños fáciles de limpiar reducen el tiempo de inactividad y permiten una mezcla segura.

Avances tecnológicos: Los temporizadores digitales y los controles programables lo ayudan a lograr una mezcla consistente y agilizar las operaciones.

También debes comparar mezcladores discontinuos y mezcladores continuos.. La siguiente tabla destaca las diferencias clave:

Factor | Mezcladores de lotes | Mezcladores continuos |

|---|---|---|

Volumen de producción | Ideal para producción continua de gran volumen | |

Eficiencia | Menos eficiente debido al tiempo de inactividad entre lotes | Más eficiente con operación continua |

Control de calidad | Posibles variaciones entre lotes | Mezcla más consistente y uniforme |

Requisitos de espacio | Huella más pequeña, más fácil de colocar en un espacio limitado | Requiere mayor espacio e infraestructura. |

Flexibilidad | Alta flexibilidad para cambios de recetas | Menos flexible debido al funcionamiento continuo |

Mantenimiento | Más fácil de limpiar y mantener | Más complejo y costoso de mantener |

Consejo: Compare siempre cómo cada mezclador maneja sus requisitos de mezcla específicos. Busque modelos que equilibren la eficiencia, flexibilidad, y facilidad de mantenimiento.

Lista de verificación de decisiones

Necesita una lista de verificación clara para guiar su elección final. Esto le ayuda a evitar errores y garantiza que los soportes de su mezclador sean seguros., mezcla fiable en su planta.

Revisa el gama de tamaños de lote planeas producir. Seleccione mezcladores que manejen lotes grandes y pequeños de manera eficiente.

Optimice el espacio de su fábrica. Elija mezcladores que se adapten a su diseño y evite aglomeraciones.

Tenga en cuenta los requisitos de la sala limpia. Múltiples mezcladores pueden aumentar los costos de limpieza.

Evaluar la utilización del equipo.. Evite mezcladores inactivos y mejore la rentabilidad.

Controlar compatibilidad con equipos existentes. Busque flexibilidad de montaje y opciones de modernización.

Confirmar el cumplimiento de certificaciones y estándares.. Sanitario 3A, FDA, clasificaciones a prueba de explosiones, y el cumplimiento del código ASME son importantes para una mezcla segura.

Establezca expectativas de desempeño claras. Considere el diseño del impulsor, caballos de fuerza del motor, longitud del eje, y manejo de viscosidad.

Elija mezcladores con diseños de bajo mantenimiento. Rodamientos sellados, limpieza en el lugar (Titubear) compatibilidad, y la disponibilidad de repuestos ayudan a reducir el tiempo de inactividad.

Explorar opciones de personalización. Seleccione estilos de impulsor, integración del tanque, clasificaciones a prueba de explosiones, y acabados sanitarios que se adaptan a sus necesidades de mezcla.

Planifique la escalabilidad y las actualizaciones. Diseños modulares, cambios de impulsor, motores más grandes, y la integración del sistema respaldan el crecimiento futuro.

Confirmar servicios de entrega y soporte.. Asistencia de inicio, piezas de repuesto, documentación de mantenimiento, y soporte de guardia mantienen su mezclador en funcionamiento.

Garantice la flexibilidad para los tamaños de lotes y las necesidades de producción.. Su mezclador debe manejar diferentes viscosidades y escalas de producción..

Cronograma mantenimiento e inspecciones de rutina dirigidas por el operador. El mantenimiento preventivo y predictivo mantiene su mezclador en óptimas condiciones.

Utilice principios de TPM como Jishu Hozen y Kobetsu Kaizen para la mejora continua y el análisis de la causa raíz..

Gestionar la seguridad, salud, y riesgos ambientales. La digitalización y el análisis predictivo ayudan a optimizar el mantenimiento.

Proporcionar programas de educación y capacitación para su equipo.. La documentación y los recursos de soporte mejoran la eficiencia del mantenimiento..

Nota: Utilice esta lista de verificación para evaluar cada opción de mezclador. Pruebe los mezcladores preseleccionados en su planta si es posible. Consultar con proveedores para confirmar detalles técnicos y servicios de soporte.. Cuando elige equipos mezcladores industriales, Protege su inversión y mejora los resultados de mezcla..

Mejorará la eficiencia y la seguridad de su planta si elige el mezclador industrial adecuado. Combine el tipo y las características del mezclador con las necesidades de su planta para obtener los mejores resultados. Pregúntate: ¿Este mezclador se adapta a su proceso?? ¿Puede manejar sus materiales?? Pruebe las opciones antes de comprar. Consulte a proveedores confiables para obtener asesoramiento experto.. Un mezclador bien elegido favorece la productividad a largo plazo y reduce el riesgo.

Preguntas más frecuentes

¿Cuál es la mejor manera de determinar el tamaño de mezclador adecuado para mi planta??

Debe revisar el volumen de su lote y sus objetivos de producción.. Consulta las especificaciones del fabricante de cada batidora.. Seleccione un modelo que coincida con su producción diaria y se ajuste a su espacio disponible.

¿Con qué frecuencia debo realizar el mantenimiento a mi batidora industrial??

Debe inspeccionar su batidora semanalmente para detectar desgaste y limpieza.. Programe un mantenimiento completo cada tres a seis meses. Siga las pautas del fabricante para la lubricación., reemplazo del sello, y controles de seguridad.

¿Puedo usar una batidora para diferentes materiales??

Puedes usar una batidora para materiales similares.. Si mezclas líquidos y polvos con diferentes propiedades, es posible que necesites mezcladores separados. Limpie siempre la mezcladora entre lotes para evitar la contaminación..

¿Qué certificaciones debo buscar en mezcladores de alimentos y bebidas??

Deberías buscar mezcladores con FDA., 3-A, e iso 9000 certificaciones. Estos estándares le ayudan a mantener la higiene y la seguridad en la producción de alimentos y bebidas..

Consejo: Solicite siempre a su proveedor documentación y resultados de pruebas antes de comprar..

**bóveda mental**

Mind Vault es una fórmula premium de apoyo cognitivo creada para adultos 45+. Está cuidadosamente diseñado para ayudar a mantener un pensamiento claro.

**gl pro**

gl pro es un suplemento dietético natural diseñado para promover niveles equilibrados de azúcar en sangre y frenar los antojos de azúcar..

**respirar**

respirar es una tintura a base de plantas elaborada para promover el rendimiento pulmonar y mejorar la calidad de la respiración..

Been hearing some buzz about 6566apuesta1. Supposedly they have some exclusive slots. Gonna create an account and see if it’s worth the hype.

Looking for some action? 0101bet1 is where its at. The place to win is now 0101apuesta1!

¿Puedes ser más específico sobre el contenido de tu artículo?? después de leerlo, todavía tengo algunas dudas. Espero que puedas ayudarme. https://www.binance.com/register?ref=IHJUI7TF