Mucha gente que trabaja en cosmética., medicamento, o los alimentos a veces se mezclan lo que hace un mezclador emulsionante homogeneizador. Piense en un grupo que prepara una crema o loción suave.. Quizás no sepan qué máquina elegir.. Un homogeneizador hace que las piezas grandes sean muy pequeñas.. Un emulsionante mezcla líquidos que no se mezclan entre sí.. Una batidora simplemente mezcla las cosas. Algunas personas se confunden con estas máquinas.:

Algunos piensan que debes agregue los polvos lentamente para que no se formen grumos. Pero las batidoras de alta velocidad pueden evitar que se formen grumos.

Muchos piensan que sólo las máquinas de alta presión pueden hacer mezclas suaves. Pero los mezcladores de una etapa también pueden hacer un buen trabajo.

El mezclador emulsionante homogeneizador adecuado ayuda a que las cosas sean más rápidas y mejores.

Control de llave

Los homogeneizadores rompen trozos grandes en otros más pequeños. Esto hace que las mezclas sean suaves y estables.. Estas mezclas se utilizan en alimentos., medicamento, y cosmeticos.

Los emulsionantes ayudan a mezclar líquidos que no se mezclan bien. Por ejemplo, mezclan aceite y agua. Esto hace que las cremas y lociones sean suaves y duren más..

Mezcladores revuelve y licúa las cosas para que todo quede parejo. Preparan mezclas para homogeneizadores o emulsionantes.

Mezcladores emulsionantes de vacío Saque las burbujas de aire mientras mezcla.. Esto hace que los productos sean suaves y sin burbujas.. También les da mejor textura y ayuda a que duren más..

Elegir la máquina adecuada depende de lo que necesite su producto. Deberías pensar en la textura., ingredientes, tamaño del lote, y que fácil es de limpiar.

Descripción general del mezclador de emulsionante homogeneizador

Conceptos básicos del homogeneizador

Un homogeneizador se utiliza en muchos trabajos.. Hace piezas grandes en mezclas más pequeñas.. Esto ayuda a que todo se mezcle bien y se sienta suave.. La máquina utiliza Fuerte presión para empujar cosas a través de espacios pequeños.. Este rompe los pedazos con fuerza y sacudiendo.. Los homogeneizadores hacen mezclas que no se separan más tarde.. Son necesarios para hacer cremas., lociones, salsas, y medicina. Hay diferentes tipos, como mecanico, alta presión, y homogeneizadores ultrasónicos. Cada tipo funciona mejor para ciertos trabajos.. Los homogeneizadores de alta presión son buenos para la leche. Los ultrasónicos ayudan a romper células en los laboratorios científicos.

Conceptos básicos de emulsionantes

un emulsionante Mezcla líquidos que no se mezclan., como el aceite y el agua. Lo hace rompiendo la pared entre los líquidos.. El emulsionante gira rápido y agita la mezcla con fuerza.. Esto hace que se formen pequeñas gotas.. La mezcla se mantiene suave y no se parte.. Los emulsionantes se encuentran en cosas como la mayonesa., lociones, ungüentos, y pinturas. Hay muchos tipos, como aniónico, catiónico, no iónico, y naturales como la lecitina. El tipo que elijas depende de lo que estés haciendo.. El sistema HLB le ayuda a elegir el emulsionante adecuado.

Consejo: Se pueden utilizar mezcladores emulsionantes vacío para sacar burbujas de aire. Esto hace que los productos sean más suaves y duren más..

Conceptos básicos del mezclador

Una batidora revuelve o mezcla cosas. Hay muchos tipos, como agitadores de tanque, licuadoras de cinta, y mezcladores planetarios. Cada uno sirve para un trabajo diferente.. Las licuadoras de cinta mezclan polvos secos.. Las batidoras de alto cizallamiento funcionan con cremas espesas. Las batidoras ayudan a garantizar que todo se distribuya uniformemente. en fábricas, Los mezcladores ayudan a los homogeneizadores y emulsionantes a preparar las cosas.. Elegir la batidora adecuada ahorra tiempo y produce mejores productos.

El grupo mezclador emulsionante homogeneizador tiene muchas maquinas. Cada uno hace un trabajo especial.. Juntos, ayudan a hacer buena comida, productos cosméticos, y medicina.

Cómo funcionan

Mecanismo homogeneizador

Un homogeneizador utiliza diferentes formas de suavizar las mezclas..

El cizallamiento ocurre cuando capas de líquido se mueven a diferentes velocidades.. Esto atrapa piezas grandes y las hace más pequeñas..

La cavitación produce pequeñas burbujas que explotan y envían ondas de choque.. Estas ondas de choque rompen las gotas..

La turbulencia significa que el líquido se mueve de forma salvaje.. Esto ayuda a que las piezas sean aún más pequeñas..

El desgarro mecánico utiliza cuchillas o paletas giratorias.. Estas partes cortan y separan la mezcla..

La fuerza de alta presión empuja los líquidos a través de espacios diminutos. Esto produce un fuerte cizallamiento y más cavitación..

La cavitación ultrasónica utiliza ondas sonoras para agitar y mezclar cosas..

Todas estas acciones ayudan al homogeneizador a suavizar las cremas y salsas.. El proceso evita que la mezcla se separe.. También mejora la textura..

Mecanismo emulsionante

Un emulsionante ayuda a mezclar líquidos como aceite y agua. Primero, rompe un líquido en pequeñas gotas dentro del otro. Moléculas especiales, como lecitina, Bajar la tensión entre los líquidos.. Estas moléculas tienen un extremo al que le gusta el agua y un extremo al que le gusta el aceite.. Cubren las gotas y evitan que se vuelvan a juntar.. El espesor del líquido principal también ayuda a mantener las gotas separadas..

Pequeño, incluso las gotas hacen que la mezcla dure más y siéntete más suave. La velocidad de mezcla y el orden de agregar elementos controlan el tamaño de la gota.. Un emulsionante de alto cizallamiento gira rápido y utiliza una gran fuerza.. Esto está bien, mezclas estables. De esta manera funciona bien para la mayonesa., lociones, y cremas. Los emulsionantes ayudan a que los alimentos y los cosméticos tengan mejor aspecto y duren más.

Consejo: Un emulsionante de alto cizallamiento puede ayudar a hacer una crema, producto suave y sin grumos.

Mecanismo mezclador

Una batidora revuelve las cosas para que queden uniformes.. Diferentes mezcladores usan diferentes formas de hacer esto.. Las batidoras de paletas mezclan suavemente las cosas y mantener su forma. Las licuadoras de cinta utilizan cintas retorcidas para mezclar bien los polvos secos.. Los mezcladores agitadores utilizan piezas giratorias para agitar líquidos y lodos.. Esto ayuda a mezclar todo uniformemente.. Mezcladores de alto cizallamiento, como el emulsionante de alto cizallamiento, Haga rápidamente piezas pequeñas y mezclas suaves.. Los mezcladores estáticos tienen partes fijas que mezclan líquidos a medida que se mueven a través de las tuberías..

Mecanismo de mezcla | Descripción & Solicitud | Efecto sobre la consistencia del producto |

|---|---|---|

Utilice paletas que se superpongan para mezclar suavemente elementos de diferentes tamaños y grosores.. | Mantenga los ingredientes a salvo de daños y mézclelos bien sin que queden ásperos.. | |

Licuadoras de cinta | Utilice cintas retorcidas para mover los polvos en todas direcciones para una mezcla uniforme.. | Asegúrese de que los polvos secos se mezclen igual cada vez para obtener una buena calidad.. |

Mezcladores agitadores | Utilice piezas giratorias para mezclar líquidos y lodos, haciendo que el líquido se mueva rápido y se mezcle bien. | Algunos impulsores se mezclan de arriba a abajo para lograr una mezcla uniforme.; otros producen un fuerte corte para mezclar y esparcir gases en líquidos. |

Mezcladores de alto cizallamiento | Utilice piezas de giro rápido para hacer rápidamente piezas pequeñas y mezclas suaves.. | Mezclar y romper piezas rápidamente hace que la mezcla sea suave y uniforme., que es importante para la cosmética y la medicina. |

Mezclar asegura que cada lote sea igual y tenga buena textura.. El mezclador adecuado ayuda al homogeneizador y al emulsionante a realizar su trabajo en la elaboración de productos..

Diferencias clave

Operación

Homogenistas, emulsionantes, y mezcladores todos trabajan a su manera. Uso de homogeneizadores presión alta para empujar líquidos a través de espacios pequeños. Esto genera fuertes fuerzas y hace que el líquido se arremoline.. Estas máquinas son difíciles de usar y necesitan trabajadores capacitados.. Usan mucha energía, especialmente con lotes gruesos o grandes. Los emulsionantes giran muy rápido y tienen cabezales especiales.. Rompen líquidos como el aceite y el agua en pequeñas gotas.. La rapidez con la que funciona un emulsionante depende de su tipo y del espesor del líquido.. Es importante mantener los emulsionantes limpios y sellados para que funcionen bien.. Mezcladores, como molinos coloidales y tipos de alto cizallamiento, utilizar menos presión que los homogeneizadores. Los molinos coloides dan fuerza media y ahorran energía.. Los mezcladores de alto cizallamiento utilizan más energía pero pueden realizar muchos trabajos de mezcla. Los mezcladores son más fáciles de usar que los homogeneizadores., pero los mezcladores de alto cizallamiento todavía necesitan una cuidadosa vigilancia.

Tipo de equipo | Presión | Velocidad/tasa de corte | Consumo de energía | Complejidad operativa | Idoneidad de la aplicación |

|---|---|---|---|---|---|

Presión alta | Tasa de corte muy alta | Alto consumo de energía | Alta complejidad | Líquidos viscosos/no viscosos; emulsiones estables a gran escala | |

Emulsionantes | Depende de la viscosidad | Varía según el tipo y el diseño del cabezal. | Consumo de energía moderado | Complejidad moderada | Varias necesidades de emulsificación. |

Mezcladores (Molinos coloides, Alto cizallamiento) | Más bajo que los homogeneizadores | Tasa de corte media a alta | Molinos coloides: eficiente; alto cizallamiento: más alto | Molinos coloides: simple; alto cizallamiento: mayor costo | Molinos coloides: viscoso/lodo; alto cizallamiento: versátil |

Los homogeneizadores son los mejores para hacer mezclas muy suaves y uniformes.. Los emulsionantes son excelentes para mezclar líquidos que no se mezclan bien.. Los mezcladores ayudan a preparar todo para los siguientes pasos.

Nota: Usar más presión en un homogeneizador no siempre mejora las cosas. Demasiada presión puede hacer que las piezas se peguen.

Aplicaciones

Cada máquina tiene un trabajo especial en alimentación, medicamento, y cosmeticos. en comida, Los homogeneizadores ayudan a producir leche., lácteos, y salsas. Hacen que la comida dure más y sepa mejor al hacer los trozos más pequeños. Esto ayuda a que los alimentos se vean bien y se mantengan frescos en las tiendas.. Los emulsionantes son muy importantes en cosmética para la elaboración de cremas y lociones.. Mezclan aceite y agua para suavizar, productos estables. Los emulsionantes pueden utilizar una aspiradora para eliminar las burbujas de aire.. Esto mejora la textura y ayuda a que la piel absorba el producto.. Cambiar la velocidad y la temperatura ayuda a crear diferentes tipos de cosméticos..

Las mezcladoras se utilizan en muchos trabajos para distribuir los ingredientes de manera uniforme.. En medicina, Los homogeneizadores y emulsionantes ayudan a fabricar medicamentos seguros y uniformes.. Estas máquinas ayudan a hacer geles, crema, y ungüentos que son siempre los mismos. en comida, Los mezcladores se aseguran de que elementos como sabores y conservantes se mezclen bien.. Esto es importante para el sabor y la calidad..

Industria | Aplicaciones típicas de homogeneizadores, Emulsionantes, y mezcladores |

|---|---|

Productos cosméticos | Los emulsionantes y mezcladores crean emulsiones estables. (crema, lociones) con textura suave y absorción consistente; sistemas de vacío y control de temperatura son críticos. |

Alimento | Homogenistas mejorar la vida útil, textura, sabor, y uniformidad reduciendo el tamaño de las partículas; Los mezcladores garantizan una incorporación uniforme de aditivos.; El control de temperatura preserva los ingredientes sensibles.. |

Farmacéuticos | La homogeneización y la emulsificación garantizan estabilidad., formulaciones uniformes; centrarse en la estabilidad y uniformidad de la formulación. |

Los homogeneizadores son mejores para alimentos como la leche y los lácteos, donde los trozos pequeños son importantes.. Los emulsionantes son los mejores para hacer cremas y geles en cosmética y medicina.. Las mezcladoras ayudan a todas estas máquinas preparando las mezclas para más pasos.

Pros y contras

Cada máquina tiene buenos puntos y algunos problemas.. Los homogeneizadores generan fuerzas fuertes y pueden mezclar muchos tipos de materiales., incluso los gruesos. Hacen mezclas muy finas y estables., que es importante para los lácteos, alimento, y medicina. Los homogeneizadores pueden funcionar todo el tiempo., entonces son buenos para trabajos grandes. Pero usan mucha energía., necesidad trabajadores calificados, y debe limpiarse con frecuencia. La alta presión también puede dañar los ingredientes a los que no les gusta el calor..

Los emulsionantes usan menos fuerza y son buenos para cosas sensibles al calor o al aire.. Funcionan en ráfagas cortas y protegen los ingredientes suaves mediante el uso de una aspiradora.. Los emulsionantes funcionan rápido y son buenos para lotes pequeños.. Pero no pueden hacer piezas tan pequeñas como lo hacen los homogeneizadores.. Mezcladores, como molinos coloides, ahorran energía y son fáciles de usar. Los mezcladores de alto cizallamiento pueden realizar muchos trabajos, pero consumen más energía y necesitan una supervisión cuidadosa..

Equipo | Fuerza de corte | Método de producción | Rango de tamaño de partículas | Materiales aplicables |

|---|---|---|---|---|

Bajo | Intermitente | nivel de micras | Materiales sensibles al calor y a la oxidación. | |

Homogeneizador | Alto | Continuo | nivel submicrónico | Amplia gama, incluyendo materiales resistentes y de alta viscosidad |

Algunos problemas son altos costos iniciales, necesitando enfriamiento, y obstrucción. Algunas máquinas no pueden manipular productos muy pegajosos o ásperos.. Los trabajadores deben estar atentos al sobrecalentamiento., piezas rotas, y necesidades de limpieza. Se necesitan trabajadores cualificados para controlar la fuerza y la temperatura.. Si no se cuida, Problemas como división o mala textura. puede pasar.

Consejo: Limpiar las máquinas con frecuencia y capacitar a los trabajadores ayuda a detener los problemas y a mantener los productos en buen estado..

Mezclador emulsionante al vacío

¿Qué es un mezclador emulsionante de vacío?

Un mezclador emulsionante al vacío es una máquina potente.. Se mezcla, mezcla, y suaviza las cosas bajo el vacío. La máquina introduce los ingredientes en un recipiente cerrado para mezclar.. El vacío saca aire., para que no se formen burbujas ni espuma. Adentro, un impulsor rápido y un emulsionador homogeneizador al vacío rompen los trozos y los mezclan bien. Esto hace que los productos como cremas y lociones sean suaves y estables.. La batidora puede calentar cosas para derretir sólidos.. También puede enfriarlos para fijar la textura.. Estas características lo hacen ideal para la medicina., belleza, y comida.

Mezclador emulsionante al vacío | Emulsionantes estándar (Alto cizallamiento / Bajo cizallamiento) | |

|---|---|---|

Principio de funcionamiento | Materiales introducidos en el recipiente de mezcla con vacío.; El impulsor rápido mezcla y elimina las burbujas de aire. | Alto cizallamiento: Descompone piezas rápidamente y en caliente.; cizallamiento bajo: Mezclado suave a velocidad media y calor. |

Función de vacío | Sí, saca burbujas de aire para una multa, mezcla suave y detiene la espuma | No |

Función de calefacción | Sí, calienta las cosas para que se derritan y las mezcle bien | Generalmente no incorporado |

Función de enfriamiento | Sí, enfría la mezcla después de calentarla para evitar que se queme o se cocine demasiado | Generalmente no incorporado |

Velocidad | Velocidad más rápida para una mezcla rápida y mejores resultados | Alto cizallamiento: rápido; cizallamiento bajo: lento |

Eficiencia | Funciona mejor, especialmente con cosas gruesas o sólidas | No tan bueno con cosas gruesas o sólidas. |

Efecto de mezcla | Hace incluso, liso, y mezclas sin burbujas | Alto cizallamiento: rompe pedazos; cizallamiento bajo: se mezcla suavemente |

Ventajas en la producción

El mezclador emulsionante al vacío de Guangzhou Guanyu es ideal para trabajos grandes. El mezclador utiliza un vacío para sacar el aire antes y durante la mezcla. Esto mantiene las cremas y lociones suaves y sin burbujas.. El emulsionante homogeneizador al vacío utiliza un rotor-estator rápido para hacer bien, mezclas constantes. Los trabajadores pueden cambiar la velocidad y el calor para diferentes recetas.. Esto ayuda a fabricar medicamentos y alimentos..

La batidora tiene muchos puntos buenos.:

se hace estable, incluso se mezcla con los mejores resultados.

El El vacío reduce la oxidación y mantiene las cosas limpias., para que los productos duren más.

El sistema puede calentar y enfriar., que mantiene seguros los ingredientes suaves.

La batidora puede manejar cosas espesas y pegajosas., Entonces funciona para ungüentos y geles..

La limpieza es sencilla con los sistemas CIP y SIP integrados.

Guangzhou Guanyu construye su mezclador emulsionante al vacío con controles inteligentes y seguros, acero fuerte. La máquina cumple con las normas GMP y se utiliza en belleza., medicamento, alimento, químico, y nuevos campos de energía. El uso de mezcladores emulsionantes al vacío ayuda a las empresas a trabajar más rápido, hacer mejores productos, y desperdiciar menos.

Nota: La tecnología de vacío en estos mezcladores brinda siempre los mismos resultados y ayuda con la automatización., por lo que son la mejor opción para las fábricas modernas.

Comparación del mezclador emulsionante homogeneizador

Tabla de comparación

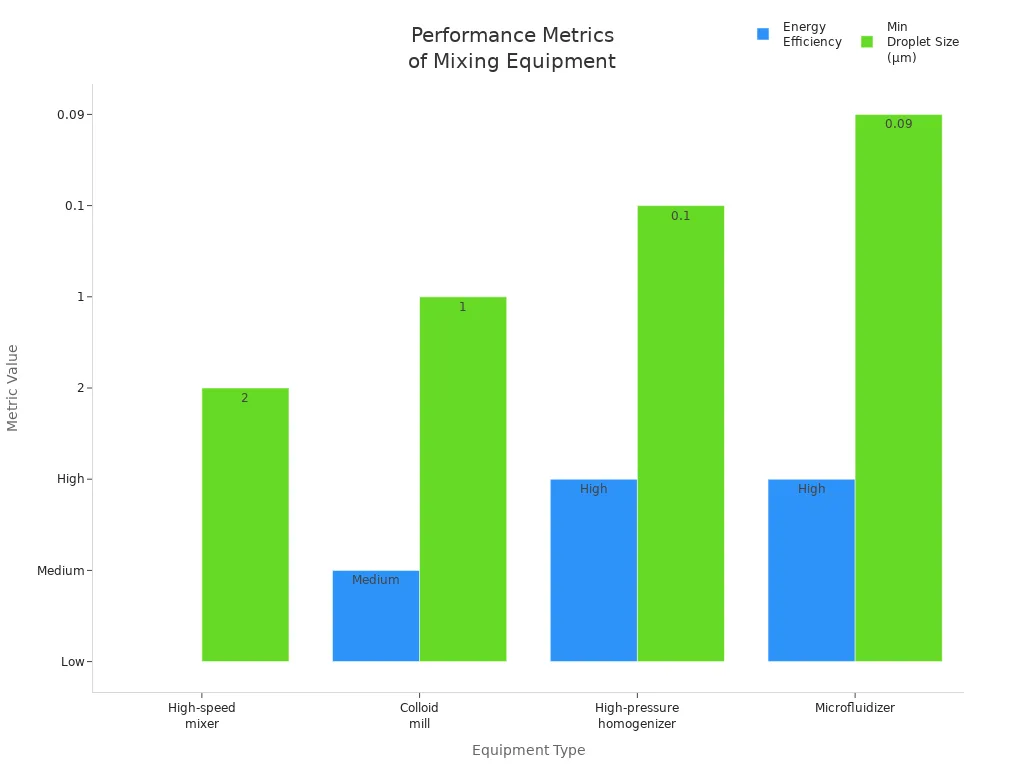

Escoger un mezclador homogeneizador, emulsionante, o batidora depende de lo que necesites. Cada máquina es mejor para determinados trabajos en alimentación., medicamento, o cosméticos. La siguiente tabla muestra en qué se diferencian estas máquinas.. Se fija en cosas como lo pequeñas que hacen las piezas., cuanta energía usan, y cuanto se pueden mezclar a la vez.

Característica | Batidora de alta cizalla | Homogeneizador | Mezclador emulsionante al vacío |

|---|---|---|---|

Utiliza rotación de alta velocidad para crear fuerza de corte. | Utiliza alta presión para reducir el tamaño de las partículas. | Se mezcla al vacío para obtener una textura suave., productos sin burbujas | |

Aplicación primaria | Emulsificación, mezcla general | Reducción del tamaño de partículas, emulsiones estables | Crema, lociones, ungüentos, alimentos sensibles |

Reducción del tamaño de partículas | Moderado (~2 µm) | Ultrafino (~0,1 µm) | Bien (nivel de micras) |

Velocidad de procesamiento | Alta velocidad, menos fino | Intensivo, soluciones estables | Rápido para materiales gruesos o pegajosos |

Eficiencia energética | Bajo a medio | Alto | Más bajo que el homogeneizador |

Rendimiento | Lote o continuo | Continuo, mezclar grandes cantidades | Más bajo que el homogeneizador |

Mantenimiento | Más fácil | Necesita más mantenimiento | Sencillo con sistemas CIP/SIP |

Mejores casos de uso | Emulsiones espesas, dispersiones | Alimentos, farmacéutico, suspensiones estables | Productos cosméticos, farmacéutico, alimento |

Los mezcladores emulsionantes al vacío funcionan sin aire en el interior. Esto elimina burbujas y grumos.. El resultado es un producto suave y uniforme.. Los homogeneizadores utilizan una fuerte presión para hacer piezas muy pequeñas.. Son buenos para mezclar grandes cantidades de alimentos y medicinas.. Mezcladores, como mezcladores de alta velocidad y molinos coloidales, usar bien menos energía. Pero hacen piezas más grandes que los homogeneizadores..

Elegir el equipo adecuado

Para elegir la máquina adecuada, debes pensar en muchas cosas. El tipo de aceites y grasas en tu receta asuntos. Algunas cosas hay que mezclarlas frías., otros necesitan calor. El orden en el que agregas cada parte puede cambiar la mezcla final.. También es importante cuánta fuerza puede soportar el emulsionante.. También debes pensar en cuánto emulsionante usar y cuánto cuesta..

Cosas clave a tener en cuenta:

Mezclando potencia y velocidad, como lo rápido que gira y lo fuerte que se mezcla

Control de nivel de vacío y temperatura para productos suaves

Buenos materiales para piezas que tocan ingredientes ásperos o afilados.

Cuánto necesitas ganar de una vez y si puedes ganar más después

Que fácil es de limpiar, como si lo pudieras desarmar o si tiene partes lisas

Si tiene controles automáticos y sensores para ayudar a ejecutarlo.

Funciones de seguridad, como paradas de emergencia y guardias

¿Cuánto cuesta comprar y seguir usando?

Consejo: Elija siempre la máquina que se adapte a su producto. Por ejemplo, una batidora homogeneizadora es ideal para preparar alimentos y medicamentos suaves. Un mezclador emulsionante al vacío es mejor para cremas y lociones suaves.. Una batidora es buena para mezclar de forma sencilla o cuando no necesitas trozos pequeños..

Guía práctica

Pasos de decisión

Elegir la batidora adecuada, homogeneizador, o emulsionante puede resultar complicado. Necesita un plan para tomar una buena decisión para su fábrica. Aquí están los pasos principales.:

Evaluar las necesidades del proceso

Primero, piensa en lo que tu producto necesita. Pregunte cuánta fuerza se necesita para mezclarlo.. Comprueba si es grueso o fino.. ver si puede manejar el calor.Comprender las propiedades de los materiales

Próximo, Mira los materiales que utilizarás.. ¿Son espesas o líquidas?? cual es su densidad? ¿Qué tan grandes son las piezas del interior?? ¿Cambiarán cuando se mezclen o se calienten??Evaluar Tipos de mezcladores

Decide si necesitas una mezcladora por lotes para trabajos pequeños. O tal vez una mezcladora continua para trabajos grandes. Los mezcladores por lotes le permiten controlar cada lote. Las mezcladoras continuas son mejores para hacer mucho a la vez..Considere la personalización

Algunos productos necesitan mezcladores especiales.. Es posible que necesites piezas diferentes o características adicionales como sellos o sensores.. Los mezcladores personalizados pueden ayudar con necesidades especiales.Pruebe antes de comprar

Pruebe primero con una batidora pequeña. Esta prueba muestra si el mezclador funciona bien con su producto..Consultar expertos

Habla con personas que fabrican batidoras o saben mucho sobre ellas.. Pueden darte consejos y ayudarte a elegir el mejor..

Consejo: Piensa en el futuro. Elija una batidora que pueda crecer con su negocio. Esto ahorra dinero más adelante..

Tipo de mezclador | Mejor para | Productos de ejemplo |

|---|---|---|

Mezcladores de bajo cizallamiento | Mezcla suave | Salsas, mezclas de frutas |

Mezcladores de alto cizallamiento | Emulsionante, rompiendo partículas | Crema, lociones |

Mezcladores de alta viscosidad | Grueso, materiales pegajosos | Pastas, adhesivos |

Errores comunes

Muchas empresas cometen errores al elegir o utilizar máquinas mezcladoras. Evitar estos errores ahorra tiempo y dinero:

Elegir una batidora que sea demasiado grande o demasiado pequeño desperdicia energía o limita la cantidad que puede producir.

No comprobar si la batidora se ajusta al producto puede provocar una mala mezcla o daños..

Olvidar si las piezas de la batidora reaccionan con el producto puede provocar contaminación o romper la máquina.

No pensar en la limpieza y el mantenimiento puede acarrear problemas de higiene.

No comprobar las funciones de seguridad, como las paradas de emergencia, pone en peligro a los trabajadores.

Sólo mirar el precio puede generar más reparaciones y pérdida de tiempo.

No pensar en automatización o controles puede provocar más errores y menor calidad.

No verificar si el fabricante brinda un buen soporte puede causar problemas más adelante.

Nota: Planifique cuidadosamente y revise sus máquinas con frecuencia. Esto los mantiene funcionando bien y mantiene sus productos seguros..

Homogenistas, emulsionantes, y los mezcladores hacen diferentes trabajos en fábricas. Los homogeneizadores hacen que las mezclas sean muy suaves para alimentos y medicinas.. Los emulsionantes ayudan a mezclar líquidos como aceite y agua.. Esto hace que las cremas y lociones sean suaves y uniformes.. Las batidoras se utilizan para mezclar cosas en general.. Elegir la máquina adecuada ayuda a fabricar mejores productos más rápido. Para trabajos especiales, Los mezcladores emulsionantes al vacío brindan más control. Hacen que los productos se sientan mejor y duren más. Estos mezcladores son ideales para artículos delicados en cosmética., medicamento, y comida.

Los mezcladores emulsionantes al vacío hacen mezclas suaves y sin burbujas.

Ayudan a mantener la alta calidad de los productos y a funcionar mejor en las fábricas..

Más empresas utilizan estos mezcladores ahora para obtener los mejores resultados.

Preguntas más frecuentes

¿Cuál es la principal diferencia entre un homogeneizador y un emulsionante??

Un homogeneizador reduce los trozos grandes para obtener una mezcla suave. Un emulsionante ayuda a mezclar líquidos que no se mezclan, como el aceite y el agua. Cada máquina tiene su propio trabajo en la fabricación de productos..

¿Cuándo debe una empresa utilizar un mezclador emulsionante al vacío??

Una empresa debe utilizar un mezclador emulsionante cuando quieren una mezcla suave y sin burbujas. Esta máquina es la mejor para hacer cremas., lociones, y ungüentos en cosmética., alimento, y medicina.

¿Puede una máquina reemplazar a todas las demás en la mezcla y emulsión??

Ninguna máquina puede hacer todos los trabajos. Homogenistas, emulsionantes, y los mezcladores tienen sus propios puntos fuertes. La mejor máquina depende de lo que estés haciendo y de cómo quieras que sea..

¿Por qué es importante eliminar el aire al mezclar??

Sacar el aire evita que se formen burbujas y espuma.. Esto hace que el producto se sienta mejor y dure más. La tecnología de vacío ayuda a crear una mezcla suave y constante..

¿Cómo apoya Guangzhou Guanyu a sus clientes??

Guangzhou Guanyu ayuda instalando máquinas, trabajadores docentes, y reparando máquinas de por vida. Sus ingenieros ayudan a personas de todo el mundo.. La empresa ofrece dos años de garantía y fabrica soluciones especiales para diferentes trabajos..

Ey, anyone else tried pg88cuming? Found some cool slots there and got a lucky spin! Hoping the good times keep rolling. Dale una oportunidad, you might just get lucky too. Just saying!

tu articulo me ayudo mucho, ¿Hay más contenido relacionado?? Gracias! https://www.binance.info/kz/register?ref=K8NFKJBQ

Can’t access YOLO247? No sweat! ‘yolo247mirror’ is your backup plan. Same great gaming, different link. Use it now with this link: yolo247mirror. Easy peasy!