When managing a food production line, selecting the right machine manufacturers is crucial. In 2025, the top 10 food machine companies are setting the standard with innovative ideas and exceptional products. These companies are recognized for leveraging advanced technology to ensure food safety, enabling faster operations and consistent production quality.

Why are these companies so significant today? Let’s explore:

Der growing demand for convenient food options and plant-based alternatives.

Cutting-edge tools like food-making robots and 3D food printers that enhance efficiency and improve product quality.

The shift toward eco-friendly materials and clean labeling, transforming the food production line.

These advancements highlight how modern technology is making food safer while aligning with consumer preferences. Whether you rely on online ERP software or desktop solutions, partnering with the right company is key to staying competitive in this rapidly evolving industry.

Key Takeaways

Picking the right food machine maker helps boost production quality.

Sondermaschinen can be made to fit exact business needs.

Green machines cut energy costs and appeal to eco-friendly buyers.

Smart tech, wie ein, speeds up work and improves accuracy.

Look for good support and warranties for lasting help and trust.

Hersteller 1: Guangzhou Guanyu

Product Offerings

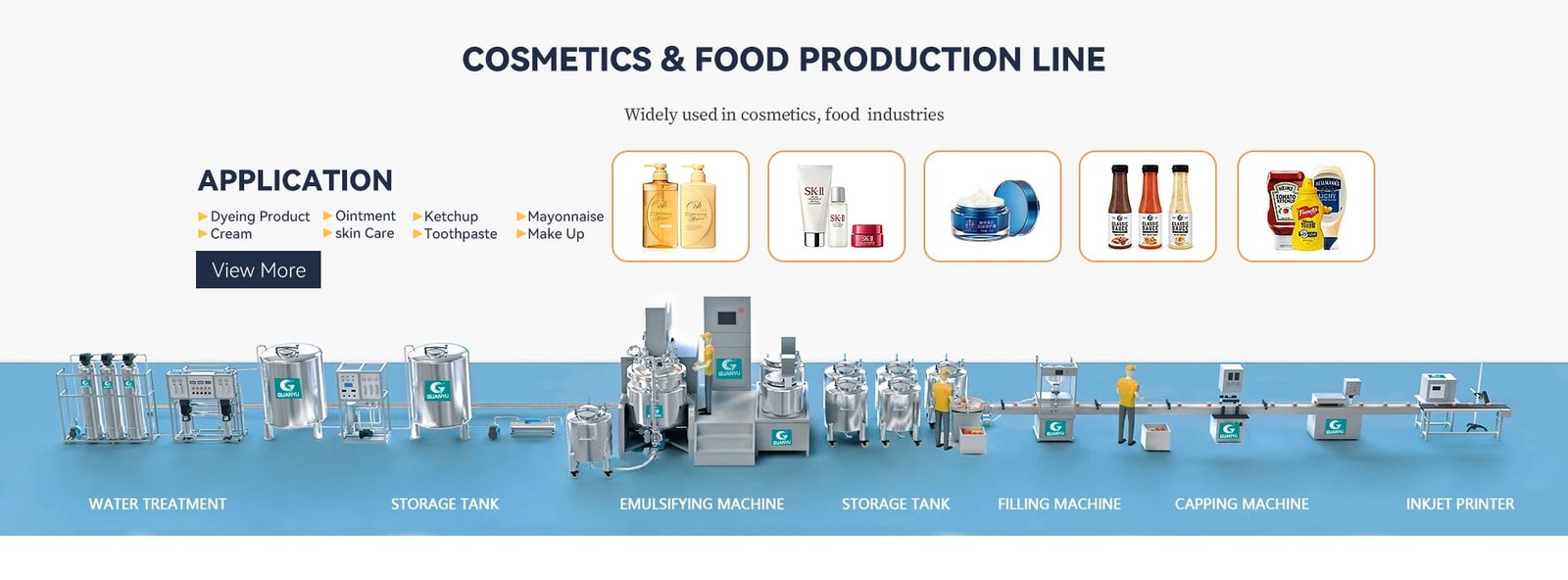

Guangzhou Guanyu is a flexible maker of food machines. They offer many tools for different production needs. Their products include mixers, vacuum emulsifiers, und Homogenisatoren. For packaging, they provide filling, Capping, and labeling machines. These machines are made with advanced technology and strong materials. This ensures they work well and are reliable.

What makes them special is their custom options. You can ask them to design machines for your needs. Whether you make cosmetics, Medizin, or food, their machines help you work faster and better.

Technical Specifications

Guangzhou Guanyu’s machines are built to work efficiently. Their designs focus on being strong and easy to use. Zum Beispiel, their vacuum emulsifiers have automatic controls for simple adjustments. Homogenizers create smooth textures, and mixing tanks blend ingredients easily.

Anwendungsszenarien

Guangzhou Guanyu’s machines are useful in many industries. In food production, they help make sauces, drinks, and baked goods. They also work well for making medicine and cosmetics.

Picture a production line where every machine runs smoothly. This reduces delays and increases productivity. Guangzhou Guanyu’s equipment helps businesses grow while keeping quality high.

Für und Wider

Guangzhou Guanyu has many reasons to be a top choice. Let’s look at the details:

Profis

Custom Solutions Tailored to You

They can make machines just for your needs. Whether you create sauces, drinks, oder Kosmetika, they’ll design tools that match your goals.Advanced Technology for Better Efficiency

Their machines have smart features like automatic controls. This makes adjustments simple and saves time. You can focus on growing your business without worrying about problems.Durability You Can Count On

Their machines are made with strong materials. This helps them last longer and work well, even in tough conditions.Umfassender Support

Buying their machines means getting great help too. They offer a two-year warranty and lifetime maintenance. Their engineers also help with setup and training.

Tipp: If you’re new to automated systems, their support makes it easier to start.

Branchenübergreifende Vielseitigkeit

Their machines aren’t just for food. They’re also used for medicine, Kosmetika, und Reinigungsprodukte. This is helpful if you want to expand your business.

Nachteile

Guangzhou Guanyu is great, but check if they meet your needs. Make sure their machines fit your production goals.

To sum up, Guangzhou Guanyu offers smart designs, strong machines, and great service. If you want to improve your production line, they’re a solid choice.

Hersteller 2: Cargill

Product Offerings

Cargill is a trusted name in food processing Maschinen. Their equipment is great for grain, meat, and animal feed. It works well and helps save resources.

Here’s why their machines stand out:

Tools that improve how food is made and its quality.

Focus on using resources wisely to protect the environment.

Smart systems that cut mistakes by up to 70%.

Cargill uses new ideas to make better machines. Their tools help businesses grow and stay ahead in food production.

Technical Specifications

Cargill’s machines are made to work fast and efficiently. They use digital twin technology to reduce downtime by 80%. AI tools make operations 30% more efficient, saving time and effort.

Their machines also save energy. This helps businesses work sustainably without losing performance. These features make Cargill’s tools a smart choice for Verbesserung der Produktion.

Anwendungsszenarien

Cargill’s machines fit into many types of factories. You can use them for grain milling, meat cutting, or making animal feed. Their systems keep quality steady, so your products stay great.

For grain, their machines help with blending and milling. For meat, they make cutting and packaging faster. In feed production, they mix and shape pellets evenly. No matter the industry, Cargill’s tools help you reach your goals.

Für und Wider

Cargill is a trusted name for food production machines. Let’s look at why they’re a good choice and what to consider.

Profis

Energy Efficiency That Saves Costs

Cargill’s machines use less energy. This helps lower electricity bills and reduces harm to the environment.Smart Technology for Better Accuracy

Their tools use AI and digital twin systems. These features reduce mistakes by up to 70%, making work easier and more reliable.Branchenübergreifende Vielseitigkeit

Cargill’s machines work for many tasks. They can mill grains, process meat, or make animal feed efficiently.Sustainability at Its Core

Cargill designs machines to use resources wisely. This reduces waste, helping both your business and the planet.Proven Reliability

Cargill has years of experience making strong, dependable machines. Their tools are built to last and work well.

Tipp: If you care about precision and eco-friendliness, Cargill’s machines are a smart choice.

Nachteile

Initial Investment Costs

Their machines may cost more at first. Check your budget before buying.Complex Features May Require Training

The advanced tools might seem hard to use at first. You may need to train your team to operate them properly.

Cargill combines new ideas with trusted performance. If you want better efficiency and eco-friendly tools, their machines are worth considering.

Hersteller 3: Tyson Foods

Product Offerings

Tyson Foods is a top maker of food processing machines. They focus on making meat, Geflügel, and plant-based food production easier. Their tools are made to improve quality and save time.

Here’s what they offer:

Meat Processing Equipment: Machines for cutting, Schleifen, and packing meat.

Plant-Based Solutions: Tools to make plant-based proteins for eco-friendly foods.

Automation Systems: Smart machines that reduce work and speed up production.

Tyson Foods doesn’t just sell machines; they provide helpful solutions. Whether you want to grow your business or try new products, their tools can help.

Technical Specifications

Tyson Foods builds strong and reliable machines. They use stainless steel to make them last longer. Many machines have automatic controls, so they’re easy to use.

Here are some key features:

Besonderheit | Nutzen |

|---|---|

Stainless Steel Build | Prevents rust and lasts a long time |

Automated Controls | Makes using the machines simple |

High-Speed Processing | Helps make more products faster |

These features make Tyson Foods’ machines work well in tough conditions. Their tools help you save time and keep your products high-quality.

Anwendungsszenarien

Tyson Foods’ machines work well in many food factories. For meat, they handle cutting, deboning, and packing. For plant-based foods, they help make protein-rich products.

Picture a factory where everything runs smoothly. Tyson Foods’ machines make this happen. You can use them to make frozen meals, snacks, or ready-to-eat foods. Their tools are flexible, so you can meet new market needs easily.

Tipp: Want to try plant-based foods? Tyson Foods’ machines make it simple to create new recipes.

Für und Wider

Tyson Foods is known for making strong and smart food machines. Let’s look at the good points and a few things to think about.

Profis

Durable and Long-Lasting Machines

Tyson Foods uses stainless steel in their machines. This keeps them from rusting and makes them tough for busy factories.Automation for Simplicity

Their machines have automatic controls. This makes them simple to use, Auch für Anfänger.High-Speed Processing

Want to make more products quickly? Tyson Foods’ machines work fast. They help you create more items without losing quality.Versatility Across Food Categories

Tyson Foods’ tools work for meat, Geflügel, and plant-based foods. They adjust to different needs, making them useful for many tasks.Focus on Innovation

Tyson Foods follows new trends. Their plant-based tools help you meet the demand for eco-friendly foods.

Tipp: Trying plant-based recipes? Tyson Foods’ machines make it easy to test new ideas.

Nachteile

Initial Cost May Be High

Tyson Foods’ machines cost a lot upfront. If you’re new, this might feel expensive.Training Might Be Needed

Some features may need training to use well. Learning them helps your team work better later.

Tyson Foods offers strong, schnell, and modern machines. If you want to grow your business or try new food ideas, their tools are a great pick.

Hersteller 4: Charoen Pokphand Foods Public Company Limited

Product Offerings

Charoen Pokphand Foods Public Company Limited (CPF) is a global leader in food manufacturing. Their machines are made for modern production needs. They provide tools for processing poultry, seafood, and livestock. CPF also offers packaging and storage machines to keep food fresh and safe.

CPF values new ideas. Their machines use advanced technology to make work easier. Automated systems reduce the need for manual labor. They also speed up production. Whether you make ready-to-eat meals or raw food, CPF’s tools help you work faster.

Technical Specifications

CPF’s machines are strong and efficient. They are made with stainless steel, which lasts long and cleans easily. Many machines have smart controls for quick adjustments.

Here’s what they offer:

Fast Processing: Handles large amounts of food quickly.

Energy-Saving Design: Uses less power to save money.

Precise Engineering: Makes sure every batch is high quality.

These features help businesses work better and faster. CPF’s machines are great for improving production and keeping standards high.

Anwendungsszenarien

CPF’s tools can be used in many places. They work well in poultry farms, seafood factories, and meat plants. They’re also useful for making frozen meals or packaged foods.

Picture a production line that runs smoothly all the time. CPF’s machines help make this possible. They reduce delays and keep everything efficient. If you want to grow your business or try new products, CPF’s tools can adjust to your needs.

Tipp: Expanding your business? CPF’s machines help meet demand while keeping quality high.

Für und Wider

Charoen Pokphand Foods Public Company Limited (CPF) makes reliable food machines. Here’s a look at the good points and things to think about.

Profis

Efficient Machines for Faster Production

CPF’s machines work quickly for big tasks. They help you finish work on time while keeping quality high.Energy-Saving Features

Their tools use less electricity. This saves money and helps the environment.Durable and Hygienic Materials

CPF uses stainless steel for their machines. This makes cleaning simple and keeps the equipment strong for years.Smart Controls for Simplicity

Many CPF machines have automatic settings. These features make them easy to adjust, so you can focus on growing your business.Versatility Across Food Categories

CPF’s machines work for poultry, seafood, meat, and packaged foods. They’re helpful if you want to add new products or make more items.

Tipp: Want machines that save energy and work well? CPF’s tools are a smart choice.

Nachteile

CPF’s machines are useful, but check if they match your needs.

Erstinvestition

Their tools might cost more at first. Think about your budget and long-term benefits before buying.Training for Advanced Features

Some automatic systems may need training. Learning how to use them will make work easier later.

CPF combines smart designs, strong materials, and great features. If you want to improve your production line, their machines are worth exploring.

Hersteller 5: Associated British Foods plc

Product Offerings

Associated British Foods plc (ABF) makes many types of food machines. Their tools help with baking, sugar making, and animal feed. These machines are strong and work well for big factories. They keep quality high while handling large amounts of food.

ABF designs machines to make production easier. They offer baking ovens, sugar systems, and milling tools. These machines save time and reduce waste. If you need reliable equipment, ABF has great options for your business.

Technical Specifications

ABF builds machines that last a long time. They use stainless steel to make them strong and durable. Many machines have automatic controls, which make them simple to use.

Zu den wichtigsten Funktionen gehören:

Energy-Efficient Design: Uses less power but still works well.

High-Speed Processing: Makes food quickly and efficiently.

User-Friendly Interfaces: Easy to operate and learn.

These features help businesses work faster and save money. ABF machines are great for improving production without spending too much.

Anwendungsszenarien

ABF machines work in many food factories. Their ovens make bread, Kuchen, und Gebäck. Sugar systems refine and package sugar easily. Milling tools create high-quality animal feed.

Imagine a factory where everything runs smoothly. ABF machines help reduce delays and improve efficiency. Whether you want to grow your business or try new products, their tools can adapt to your needs.

Tipp: Want to make your production better? ABF machines are a smart choice.

Für und Wider

When choosing food production tools, Associated British Foods plc (ABF) stands out. Let’s look at the good points and a few challenges to think about.

Profis

Energy Efficiency That Saves Money

ABF machines use less power but still work well. This lowers your electricity bills and helps the environment.Strong and Long-Lasting Machines

Made with stainless steel, these machines are tough. They can handle heavy use without needing frequent repairs.Easy-to-Use Features

ABF machines have simple controls. Even beginners can learn to use them quickly.Fast Processing for More Production

These machines work quickly and handle large tasks. They help you make more products without losing quality.Works for Many Food Types

ABF machines are flexible. They can bake bread, refine sugar, or make animal feed. This makes them great for businesses wanting to try new products.

Tipp: Expanding your product range? ABF machines make it easy to add new items.

Nachteile

High Starting Costs

ABF machines may cost more at first. But their long-lasting design and efficiency can save money over time.Training Might Be Needed

Some advanced features may take time to learn. Training can help you use the machines better.

ABF provides strong, effizient, and flexible machines. If you want reliable tools for your business, they’re a great choice for long-term success.

Hersteller 6: Danone

Product Offerings

Danone is known for making machines that focus on Gesundheit Und sustainability. Their tools work well for dairy, plant-based drinks, and bottled water. Whether you make yogurt, almond milk, or mineral water, their equipment keeps production smooth.

Danone’s machines include filling systems, pasteurizers, and packaging tools. These help keep products fresh and reduce waste. Ihre modular designs let you adjust machines to fit your needs. This makes them great for businesses wanting to grow or try new products.

Technical Specifications

Danone uses smart technology to improve production. Their machines have AI systems to make work faster and easier. Zum Beispiel, they teamed up with IBM to add AI and IoT tools. These monitor things like temperature and speed to keep quality steady.

Here’s what their machines can do:

Besonderheit | Nutzen |

|---|---|

AI Supply Chain Tools | Better forecasting and inventory management. |

Echtzeitüberwachung | IoT tools track temperature and speed during production. |

Efficiency Boost | |

Waste Control | Predictive tools reduce waste and prevent overproduction. |

These features make Danone’s machines dependable and save time and energy.

Anwendungsszenarien

Danone’s tools are perfect for making healthy and eco-friendly products. You can use them for dairy foods like yogurt and cheese or plant-based drinks like oat milk. They also work well for bottling water, keeping it clean and fresh.

Picture a factory where everything runs smoothly. Danone’s machines help reduce delays and improve production. Whether your business is small or large, their tools adjust to your needs.

Tipp: Want to try plant-based recipes? Danone’s modular machines make experimenting easy.

Für und Wider

Danone’s food machines have many great features. Aber, like all products, there are pros and cons to consider. Let’s look at both sides.

Profis

Health-Focused Technology

Danone’s machines help make healthy foods and drinks. They’re ideal for dairy, plant-based drinks, and bottled water. If your business values eco-friendly and nutritious items, these tools are a good choice.Energy Efficiency That Saves Money

Their machines use smart systems to save energy. This lowers electricity costs and helps the environment.Modular and Flexible Design

Need changes in your production line? Danone’s machines can adjust easily. They’re great for growing businesses or testing new recipes.Smart Technology for Better Control

AI tools let you watch production as it happens. This helps fix problems early and keeps quality steady.Sustainability at Its Core

Danone’s machines are made to reduce waste. They help businesses meet eco-friendly goals.

Tipp: Trying plant-based recipes? Danone’s machines make experimenting simple.

Nachteile

Higher Initial Costs

These machines cost more upfront. But they save money later by using less energy and reducing waste.Learning Curve for Advanced Features

The smart tools may seem tricky at first. Training your team will help them use the machines better.

Danone’s machines combine smart designs with eco-friendly features. They’re great for making healthy products. Just be ready to spend time on setup and training.

Hersteller 7: The Kraft Heinz Company

Product Offerings

The Kraft Heinz Company is famous for its food products. They also make machines for food production lines. These machines help create condiments, frozen meals, and snacks. Their tools are made to keep quality steady every time.

Their equipment includes filling systems, packaging machines, and processing tools. These machines handle large amounts of food while staying accurate. If you need dependable tools to grow your business, Kraft Heinz can help.

Technical Specifications

Kraft Heinz designs machines to work efficiently and follow rules. Their tools meet strict laws to ensure products are safe and legal. Zum Beispiel, their ketchup machines follow sodium limits for healthier options.

Here’s a summary of their features:

Feature Type | Details |

|---|---|

Nutrition Goals | Targets for energy, sodium, Zucker, and fat in 51 food types. |

Legal Compliance | Machines meet rules like sodium limits for ketchup. |

Balancing Challenges | Reduces sodium while keeping food safe and tasty. |

These features make Kraft Heinz machines ideal for businesses focused on health and quality.

Anwendungsszenarien

Kraft Heinz machines work well in many factories. Imagine a ketchup line where bottles are filled and sealed perfectly. Or a frozen meal line where food is portioned and packed quickly. Their tools keep production smooth and meet market needs.

Their machines are flexible too. You can use them for sauces, ready meals, or plant-based foods. This makes them great for businesses wanting to try new products.

Tipp: Expanding your product line? Kraft Heinz machines adjust to your needs easily.

Für und Wider

Kraft Heinz makes machines with many good features. Aber, there are a few things to think about before choosing them.

Profis

Reliable Quality Control

Their machines follow strict health rules. They keep your food safe and consistent every time.Works for Many Products

You can use their machines for sauces, frozen meals, or snacks. This makes them helpful if you want to try new products.Helps Make Healthier Foods

Kraft Heinz machines help balance sodium in foods like ketchup. They make healthier options without losing flavor.Strong and Energy-Saving Design

These machines last a long time and save power. They’re great for big factories and help lower costs over time.Famous and Trusted Brand

Kraft Heinz is well-known for food. Using their machines means working with a company that knows the industry well.

Tipp: Need machines that are reliable and flexible? Kraft Heinz is a great choice.

Nachteile

Costs More at First

Their machines might be expensive to buy. Wenn Ihr Unternehmen klein ist, this could be hard to manage.Advanced Features Need Training

Some tools may be tricky to use at first. Training your team will help them learn faster.

Notiz: The upfront cost and training might seem tough, but the benefits later are worth it.

Kraft Heinz machines are strong, schlau, and flexible. If you want tools that improve your production line, they’re a good option.

Hersteller 8: Mars

Product Offerings

Mars is famous for its snacks and pet food. They also make machines for food production. Their tools help create chocolate, candies, and kibble for pets. Mars designs equipment to work fast and keep quality steady.

Mars stands out because they focus on new ideas. Their machines save energy and reduce waste. Zum Beispiel, their chocolate tempering tools make smooth chocolate while using less power. If you need strong machines to grow your business, Mars has great options.

Technical Specifications

Mars makes machines that are tough and easy to clean. Sie verwenden Edelstahl, which lasts long and stays hygienic. Many machines have automatic settings, making them simple to adjust.

Here’s a quick look at their features:

Besonderheit | Nutzen |

|---|---|

Stainless Steel Build | Robust und leicht zu reinigen |

Automated Controls | Easy to use and adjust |

Energy-Saving Design | Uses less electricity |

These features make Mars machines perfect for reliable and efficient production.

Anwendungsszenarien

Mars machines work well in different factories. You can use them to make chocolate bars, wrap candies, or produce pet food. Their tools are flexible and help meet market needs.

Picture a factory where everything runs smoothly. Mars machines keep production steady and reduce delays. Whether you want to make more snacks or start making pet food, their tools can help.

Tipp: Want to try new products? Mars machines make it simple to expand your business.

Für und Wider

Mars makes great machines for food production. Aber, like anything, there are good points and some challenges. Here’s a simple breakdown:

Profis

Durable and Hygienic Materials

Mars machines use stainless steel. This keeps them strong and easy to clean. You won’t have to worry about rust or germs.Energy Efficiency That Saves Money

Their machines use less electricity. This helps lower energy bills and is better for the planet.Automation for Simplicity

Many Mars machines have automatic controls. These make them easy to use, Auch für Anfänger.Versatility Across Product Lines

Mars machines can make chocolate, candies, or pet food. This is helpful if you want to try new products.Focus on Innovation

Mars works hard to improve their tools. Zum Beispiel, their chocolate machines save power while making smooth, high-quality chocolate.

Tipp: Need eco-friendly and reliable machines? Mars is a great choice.

Nachteile

Initial Investment Costs

Mars machines can be expensive at first. If your budget is small, this might be tricky.Training Might Be Needed

Some features may take time to learn. Training your team will help them use the machines better.

Notiz: The upfront cost and training might seem hard, but the benefits later are worth it.

Mars offers strong, schlau, and efficient machines. If you want tools to grow your business, they’re a good option.

Hersteller 9: Mondelez International

Product Offerings

Mondelez International is known for making snack production machines. Their tools help create cookies, crackers, and chocolates. These machines handle large amounts while keeping quality steady.

Mondelez uses open innovation to improve their products. They gather ideas from different groups to make better machines. This mix of teamwork and creativity gives them an advantage over others.

They also care about the environment. Mondelez designs machines to lower carbon emissions. Their goal is to reach net zero emissions by 2050. They even host events to find greener ways to make snacks.

Technical Specifications

Mondelez machines are made to work fast and reliably. They use automation to make production easier and reduce waste. Many machines have tools to watch production in real time and fix problems quickly.

Here’s a quick look at their features:

Besonderheit | Nutzen |

|---|---|

Automated Controls | Makes work easier and faster |

Echtzeitüberwachung | Hält die Produktqualität stabil |

Energy-Efficient Design | Uses less electricity |

These features make Mondelez machines great for eco-friendly and efficient production.

Anwendungsszenarien

Mondelez machines are perfect for snack factories. Picture a line where cookies are baked, packed, and ready to ship without delays. Their tools keep everything running smoothly.

You can also use their machines for chocolates or crackers. Whether you want to make more snacks or try new recipes, Mondelez tools adjust easily. Their focus on sustainability helps you offer better choices to customers.

Tipp: Looking for machines that match modern trends? Mondelez is a smart pick.

Für und Wider

Mondelez International makes machines with great features. Let’s look at the good points and a few challenges to think about.

Profis

Eco-Friendly Design

Mondelez machines save energy and lower electricity use. This helps you save money and meet eco-friendly goals. 🌱Real-Time Monitoring for Quality

Their tools let you watch production live. This helps catch problems early and keeps quality high.Works for Many Snack Types

These machines can make cookies, crackers, or chocolates. They’re great for businesses wanting to try new products.Focus on Innovation

Mondelez improves machines by using ideas from many sources. This helps you stay ahead in the market.

Tipp: Want eco-friendly and modern machines? Mondelez is a smart choice.

Nachteile

High Starting Costs

These machines cost more at first. Small businesses might find this hard to manage.Training Needed for Advanced Features

Learning to use the smart tools takes time. Training your team will help them use the machines better.

Notiz: The upfront cost and training may seem tough, but the benefits later are worth it.

Mondelez International offers eco-friendly, innovativ, and flexible machines. If you want to improve your production line, their tools are a great option.

Hersteller 10: Albertsons Companies

Product Offerings

Albertsons Companies is a top maker of food production machines In 2025. Their tools help with sorting fresh food and packing ready meals. They focus on making machines that improve work and keep food safe.

Albertsons has many tools like sorting systems, packaging machines, and cold storage units. These machines make work faster and easier. They are great for big factories that need to keep food quality steady.

Albertsons is special because they use new ideas. Their machines have ERP systems to track and improve work. This technology helps cut waste, manage supplies better, and boost productivity.

Technical Specifications

Albertsons makes machines that are smart and dependable. Their sorting tools use AI to pick the best fruits and veggies. This makes sure only good food moves forward in production.

Their packaging machines have sensors that adjust settings automatically. This speeds up packing and reduces mistakes. Cold storage units keep food fresh by controlling temperature, which is great for items that spoil quickly.

Albertsons also follows strict food safety rules. Their machines meet high standards to keep food safe for customers. Automated checks make following rules easier and save time.

Anwendungsszenarien

Albertsons machines work in many types of food factories. You can use them in bakeries, dairy plants, or frozen food factories.

Picture a factory where fresh food is sorted, packed, and stored perfectly. Albertsons machines make this happen by automating every step. Their tools are also great for making ready-to-eat meals, which are popular now.

Albertsons uses smart technology to help businesses stay ahead. Their ERP systems track progress and show areas to improve. This keeps your factory running well and helps you make great products for your customers.

Für und Wider

Albertsons Companies makes some of the best food machines in 2025. Here’s a simple look at the good points and a few challenges.

Profis

Smart Sorting Technology

Their AI tools pick the best fruits and veggies. This helps keep your products high-quality.Energy-Efficient Cold Storage Units

These storage units use less power and keep food fresh. You save money and help the planet.Fast and Accurate Packaging

Their packaging machines have sensors that adjust settings. This speeds up work and reduces mistakes.ERP Systems for Easy Tracking

Albertsons machines include ERP tools to manage supplies. These systems cut waste and improve production control.Meets Food Safety Rules

Their machines follow safety laws automatically. This makes it simple to keep food safe without extra work.

Tipp: Need reliable and efficient machines? Albertsons is a great choice.

Nachteile

Costs More at First

Albertsons machines can be expensive to buy. If your budget is small, this might be hard.Training Needed for ERP Tools

Learning the ERP features takes time. Your team will need practice to use them well.

Notiz: The upfront cost and training may seem tough, but the benefits later are worth it.

Albertsons Companies offers smart and dependable machines. If you want to improve your factory, their tools are a good option.

Vergleichstabelle

Schlüsselmerkmale

Each food machine company has its own strengths. Some focus on new technology, while others aim for quality or eco-friendly designs.

Here’s a simple list of standout features:

Guangzhou Guanyu: Custom machines that boost efficiency in many industries.

Cargill: Energy-saving tools that cut waste and improve operations.

Tyson Foods: Strong machines with easy automation for big factories.

Danone: Smart designs with AI to improve food safety.

Mars: Flexible tools for snacks and pet food with eco-friendly focus.

Every company is good at different things. Pick one based on your factory’s needs.

Differences in Technical Specifications

Technical details matter when choosing machines. Some are fast, others focus on accuracy or saving energy.

Hersteller | Key Feature | Nutzen |

|---|---|---|

Guangzhou Guanyu | Makes work faster and consistent | |

Cargill | Digital twin technology | Cuts downtime by 80% |

Danone | AI and IoT tools | Improves food safety standards |

Mondelez International | Echtzeit-Überwachungssysteme | Hält die Produktqualität stabil |

Albertsons Companies | ERP tracking systems | Boosts factory efficiency |

These features show how each company uses smart ideas to meet different needs.

Anwendungseignung

Not all machines work for every factory. Some are best for big tasks, while others fit smaller jobs.

Schlüsselaspekt | Beschreibung |

|---|---|

Zweck | |

Methodology | Finding top performers using data and research methods. |

Stakeholders | Info designed for patients, doctors, and decision-makers. |

Challenges | Differences in coding and methods for global comparisons. |

Zum Beispiel, Guangzhou Guanyu’s machines work well for cosmetics and medicine. Tyson Foods focuses on meat and plant-based food production. If you need ERP software, Albertsons Companies offers tools to manage factory systems.

Pick a manufacturer based on your goals. Whether you want fast machines or eco-friendly designs, there’s a perfect choice for you.

Picking the best food machine maker can improve your business. Each company has special strengths, like smart tools or eco-friendly designs. Guangzhou Guanyu makes custom machines, while others focus on green methods or smart data tools.

Here’s why choosing the right maker is important:

Smart tools make work faster and keep quality steady.

Green methods cut waste and attract eco-friendly buyers.

Local partnerships and making parts in-house save money.

Check out these companies to find the best fit for you. The right choice can make your factory better and help you succeed in 2025.

FAQ

What should you consider when choosing a food production line manufacturer?

Find manufacturers that meet your factory’s needs. Check their products, custom options, and support services. Auch, look at their reputation for being reliable and creative.

Tipp: Ask about warranties and repairs before buying anything.

How do custom machines benefit your production line?

Custom machines are made to match your needs. They help your factory work faster and waste less. These machines fit your processes, so you don’t need many changes.

Example: Guangzhou Guanyu makes special machines for food, Kosmetika, und Medizin.

Are eco-friendly machines worth the investment?

Ja! Eco-friendly machines use less energy and create less waste. This saves money over time and attracts customers who care about the planet.

🌱 Bonus: Mondelez International designs machines to help you meet green goals.

Can small businesses afford advanced food production machines?

Some machines cost a lot at first but save money later. Look for companies that offer flexible tools or payment plans.

Für die Spitze: Choose machines that can do many tasks as your business grows.

Why is after-sales support important?

After-sales support helps keep your machines working well. It includes training, fixing problems, and regular check-ups to avoid delays.

Reminder: Guangzhou Guanyu provides lifetime help and training for their machines.

Oro777, no es mi favorito, pero tiene lo suyo. Si buscas algo diferente, quizás te guste. Por si acaso, aquí te va el link oro777.

In Ordnung, so I gave gamehay88 a go. Not bad, not bad at all! Lots of games to keep you busy. I think it’s awesome and I think you should check. gamehay88