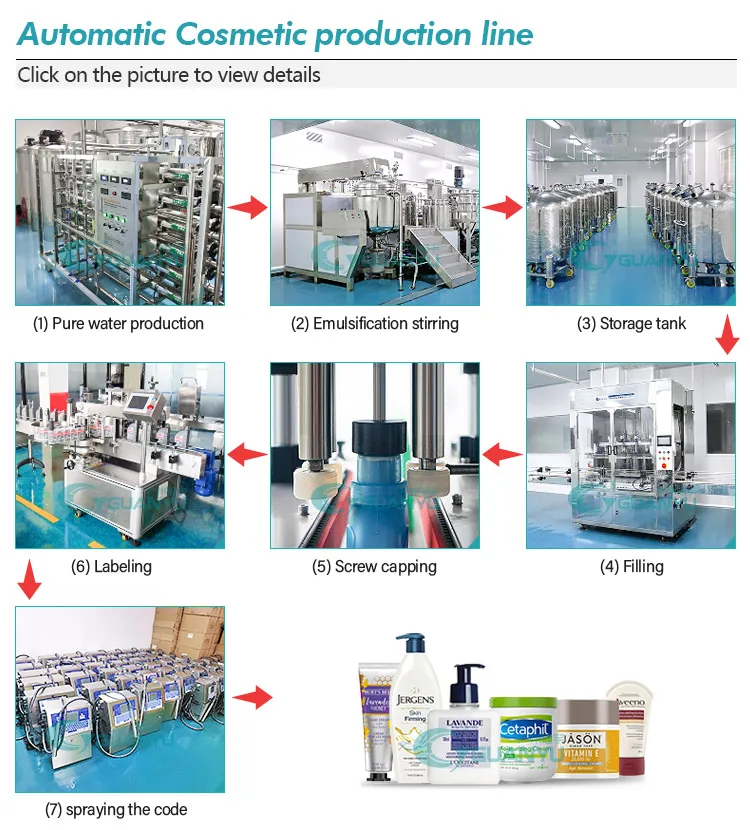

Vakuummischer, homogenisierende Emulgiermaschine, Körperlotion, Vakuumemulgator, Gesichtscreme, Kosmetik, Mayonnaise-Herstellungsmaschine

Produktbeschreibung

Einführen:

Struktur:Mischtanks aus Edelstahl werden im Getränk weit verbreitet, Essen, Molkerei, Chemikalie- und Prozessindustrie Gebrauchsmixer Tank, Puffertank und Lagertank, die für sanitäre Standards reinigbar sind .1.Capacity :100-20000L 2. SINGLE -Schicht/ Doppelschichten/ Drei Schichten3.Motorleistung:0.75-5.5KW4.Materialien sind alle Sanitärstahl aus Edelstahl. 5. Humanisierte Strukturdesign und leicht zu bedienen. :1.Schnelles offenes Mannloch .2. Varianische Arten von CIP -Reinigungsmitteln .3.Fly und insektenresistent sanitäre Atembedeckung .4. (Nach Kundenanforderungen ).7.Leiter (Nach Kundenanforderungen).8.Paddelmixer. (Nach Kundenanforderungen) .10.Eddy-Proof-Board .

Modell | Volumen(L) | Mischkraft(kw) | Rotationsgeschwindigkeit des Mixers(U/min) | Homogenisierende Kraft(kw) | Homogenisierende Rotationsgeschwindigkeit(U/min) | Heizmethode |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Dampfheizung oder Elektroheizung |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

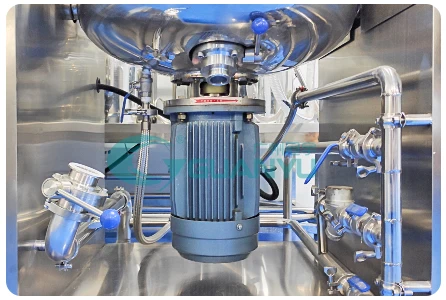

Rührpaddel

Frequenzumwandlungsgeschwindigkeitsregelung 0-62 U/min, Die Form der Klingen wird entsprechend Ihren Materialien gestaltet.

Homogenisator

Frequenzumwandlungsgeschwindigkeitsregelung 0-3000 U/min, Homogener Scherkopf, Hochgeschwindigkeits-Schermaterialien, so dass die Materialien vollständig gebrochen und vermischt werden!

Öl-Wasser-Topf

Wasserphase vor der Behandlung System und

Ölphase-Topf zum Vorhitzen und Verbreiten

die Rohstoffe, Dann übertragen Sie sie auf

Haupttopf, um mit der Produktion zu beginnen.

Ölphase-Topf zum Vorhitzen und Verbreiten

die Rohstoffe, Dann übertragen Sie sie auf

Haupttopf, um mit der Produktion zu beginnen.

Konsole

Das Bedienfeld zeigt und steuert die Ausrüstungstemperatur, mischen, Homogenisierung, Druckdaten, usw. in echt

Zeit.

( Optionale SPS-Steuerung )

Zeit.

( Optionale SPS-Steuerung )

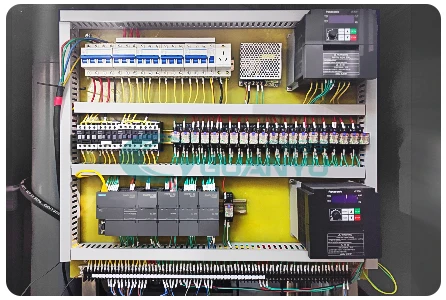

Elektrische Box

Verwenden Sie international bekannte Markenkomponenten, um die Qualität der Geräte und eine längere Lebensdauer zu gewährleisten

Service

Wir werden Zeichnungen entsprechend Ihren Anforderungen entwerfen und One-Stop-Lösungen bereitstellen.

Produkt Konfiguration

Über uns

Erfolgreicher Fallprozess

Zertifizierungen

FAQ

Rezensionen

Es liegen noch keine Bewertungen vor.