Füll- und Verschließmaschine für Aluminium-/Schlauchrohre

Produktionsgeschwindigkeit: | 30-80 Stück/Min |

Füllvolumen: | 5-300ml/Stück |

Füllgenauigkeit: | ≤±0,5 % |

Anwendbarer Rohrdurchmesser: | 13.5-60mm |

Anwendbare Rohrlänge: | bis zu 230mm |

Stromspannung: | 380V |

Arbeitsdruck: | 0.6Mpa |

Größe: | 2.38×1,2×2,3(M) |

Nettogewicht: | 1500kg |

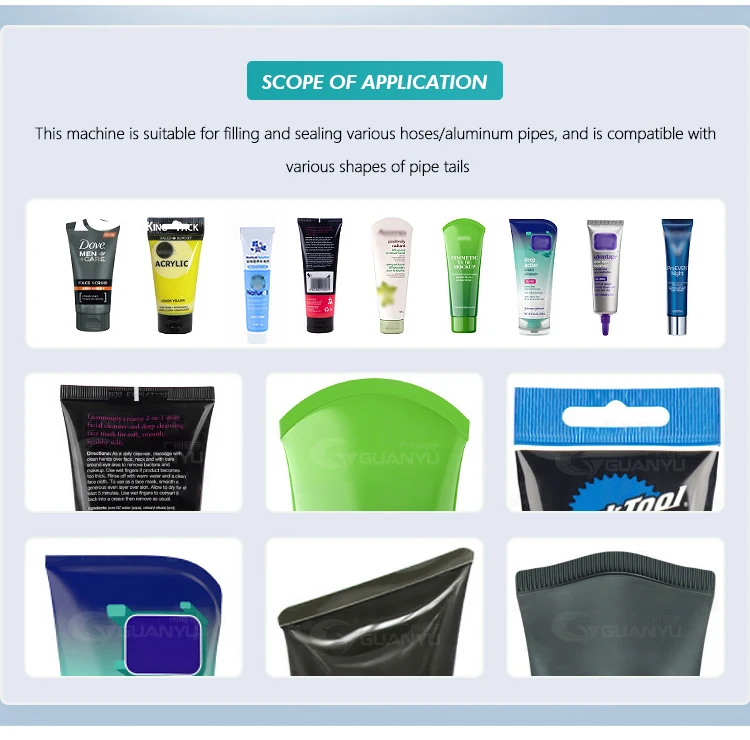

Optional: | Schlauch/Aluminiumrohr/Metallrohr |

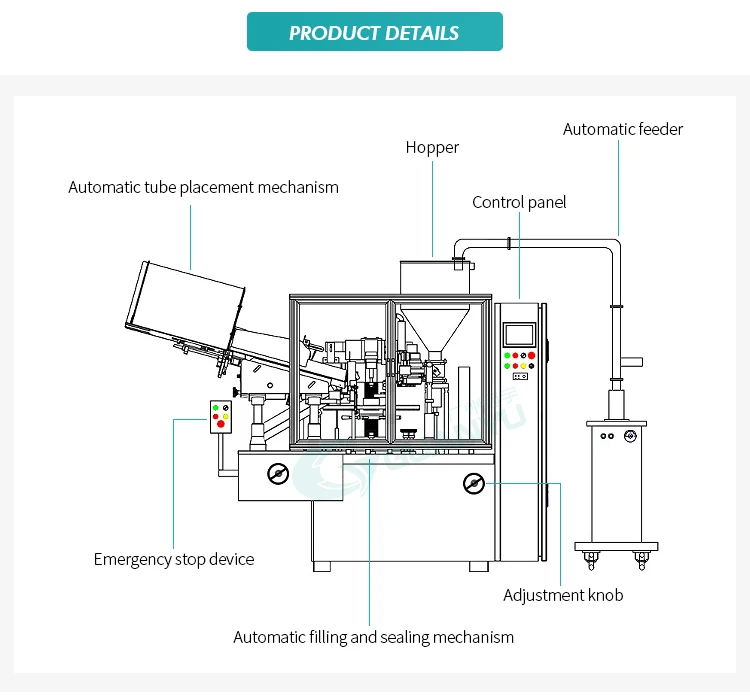

①Automatischer Rohrlademechanismus:

Stecken Sie die Röhrchen in den Schlitz und sie werden automatisch durch den Tunnel zur Arbeitsablage transportiert.

②Arbeitstablett:

Die Form, in der das Rohr platziert wurde, Der Durchmesser kann individuell zwischen 13,5 und 60 mm angepasst werden, Eine Maschine kann mehrere Formensätze für mehr Rohre mit unterschiedlichen Durchmessern anpassen

③Automatische fotoelektrische Identifizierung und Benchmarking:

Dieser Sensor dient zur automatischen Ausrichtung des Rohrs entsprechend der Farbmarkierung am Rohrende

④Präzisionsfüllung:

Fülldüsen werden an unterschiedliche Rohrdurchmesser angepasst, um eine Befüllung ohne Spritzer/Überlauf zu gewährleisten

①Rohrendenfaltvorrichtung:

Kombination mehrerer Biegeprozesse, Klemmen und Falten, Es dient zum Abdichten des Rohrendes. Das Datum kann im versiegelten Zustand auf das Heck gedruckt werden

②Automatisches Entladen:

Von hier aus wird das fertige Rohr automatisch entladen

Code deines Schicksals –

Ich bin äußerst inspiriert von Ihrem Schreibtalent und auch von der Struktur Ihres Weblogs. Ist, dass dies ein bezahltes Thema oder haben Sie es selbst geändert? Wie auch immer, mach weiter so, das gute Qualitätsschreiben, Es ist heutzutage selten, einen so großartigen Blog wie diesen zu lesen!