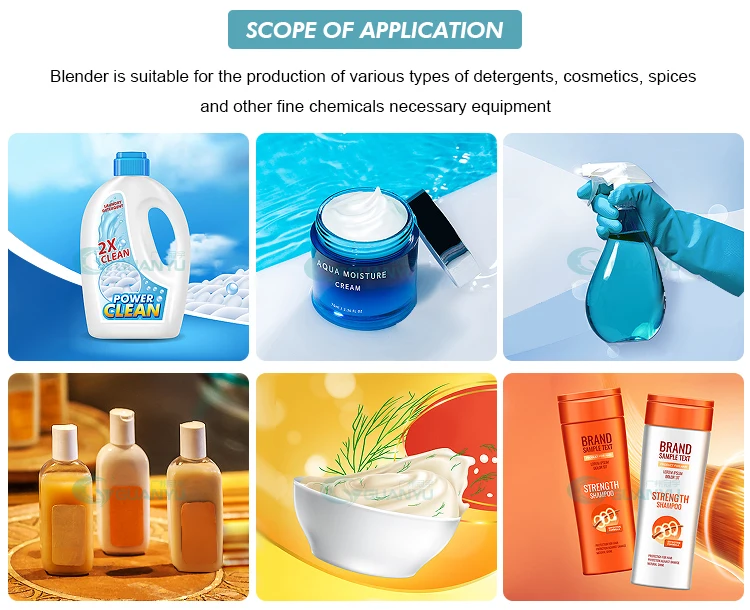

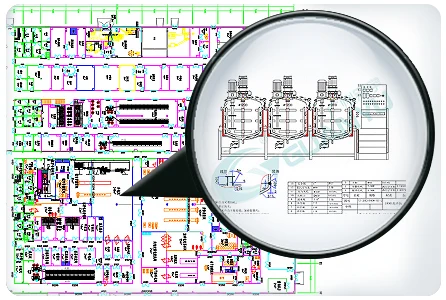

Customized 5000L Liquid Detergent Mixing Machine Detergent Production Plant Chemical Liquid Soap Mixing Tank Making Machine

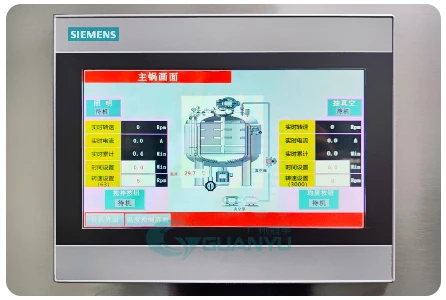

Merkmale:1. The material of contacted part is SUS316L stainless steel, inside and outside of the equipment are with mirror polishing and get to GMP standard.2. All pipelines and parameter are controlled automaticlly. And the electric appliance which are imported from foreign country,like Siemens ,Schneider and so on.3. Emulsifying tank is with CIP cleaning system,it make the cleaning to be easy and effective.4.Emulsifying tank adopts tertiary agitating system, and during the emulsification ,the whole processing is under a vacuum environment, so it not only can eliminate spume which created in the emulsification processing ,but also can avoid the unnecessary pollution.5. The homogenizer adopts the most advanced technology,it can get a ideal emulsifying effect.The speed of high emulsification is 0-3600r/min, and the speed of low mixing is 0-63r/min.

Modell | Volumen(L) | Mischkraft(kw) | Rotationsgeschwindigkeit des Mixers(U/min) | Homogenisierende Kraft(kw) | Homogenisierende Rotationsgeschwindigkeit(U/min) | Heizmethode |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Dampfheizung oder Elektroheizung |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

Rührpaddel

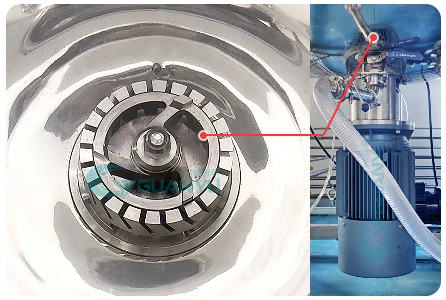

Homogenisator

Frequenzumwandlungsgeschwindigkeitsregelung 0-3200 U/min, Homogener Scherkopf, Hochgeschwindigkeits-Schermaterialien, so dass die Materialien vollständig gebrochen und vermischt werden!

◭Die Allround-Mischung zum Schaben von Wänden nutzt den Frequenzumrichter zur Geschwindigkeitsanpassung , so dass qualitativ hochwertige Produkte von unterschiedlichen Prozessen gemäß den Kundenanforderungen.

Vakuumpumpen

Plate and frame heat exchanger

Material hoist

Pneumatikventil

Konsole

Service

1..Wer sind wir?

Rezensionen

Es liegen noch keine Bewertungen vor.