Industrieller Mischbehälter, kosmetischer Creme-Homogenisator, Vakuum-Emulgiermaschine, Maschine zur Herstellung von Gesichtslotion

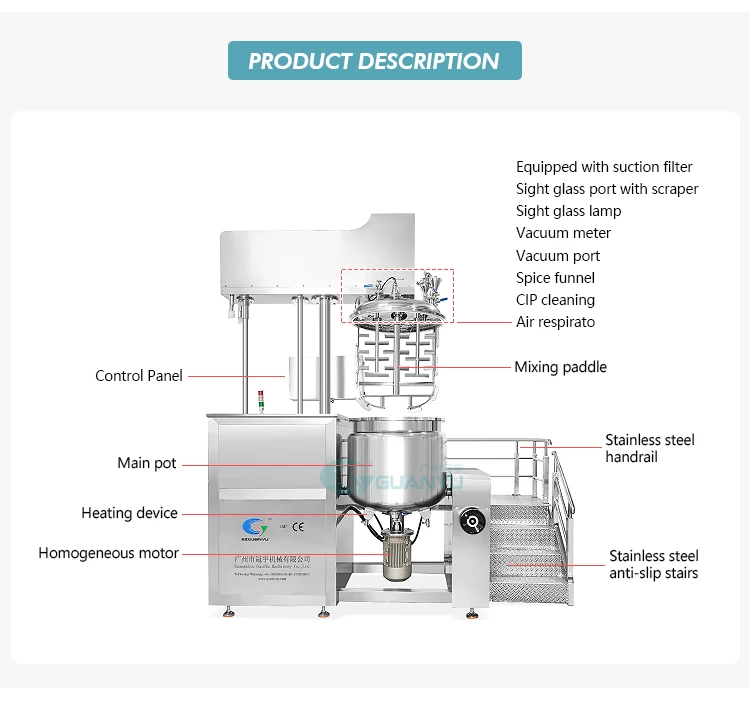

Produktbeschreibung

Modell | Effektive Kapazität | Emulgieren | Agitator | Außendimension | Die Verdienste(KW) | |||

KW | U/min | KW | U/min | Länge*Breite*Höhe (mm) | Max h | |||

20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800*1600*1850 | 2700 | 5 |

50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700*2000*2015 | 2700 | 7 |

100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2920*2120*2200 | 3000 | 10 |

150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110*2120*2200 | 3100 | 11 |

200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150*2200*2200 | 3100 | 12 |

350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650*2650*2550 | 3600 | 17 |

500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970*2800*2700 | 3950 | 19 |

750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780*3200*3050 | 4380 | 24 |

1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900*3400*3150 | 4550 | 29 |

1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000*4100*3750 | 5650 | 42 |

2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850*4300*3600 | / | 46 |

Einführung1. Die Maschine hat einen dreifachen Mixer, Hydraulische Aufzugsabdeckung, Hochgeschwindigkeits-Homogenitätsmixer (Die Geschwindigkeit beträgt 0-3500R/min, Frequenzgeschwindigkeitsregulierung) und Schabermixer mit niedriger Geschwindigkeit (Die Geschwindigkeit beträgt 0-40R/min, Frequenzgeschwindigkeitsregulierung). Im Homogenisator-Teil wird schnell geschnittener Wirbelemulgierungsmixer verwendet, das kann mit niedriger Geschwindigkeit kratzen und automatisch mischen und sich bis zum Boden und die Wand des Kessels kuscheln. Die Maschine zeichnet Pulvermaterial auf dem Weg des Vakuums, um das Fliegen des Pulvers zu verhindern. Das gesamte Arbeitsverfahren wird im Vakuumzustand durchgeführt, um zu verhindern. CIP -Reinigungssystem ist in diesem System ausgestattet. Der Kontaktteil von Gefäß und Material besteht aus SUS316L -Material. Spiegelfinish der Innenoberfläche beträgt 300EMSH. Um die Stabilisierung der Kontrolle zu gewährleisten, Die Vakuumpumpe ist die Produkte der Deutschland Siemens Company, Der Knopf wird von Japan Fujicompany erzeugt, Der Wandler ist das Produkt der Japan Matsushita Electric Industries und der Elektro-Kontroll-Teil ist das Produkt der Siemens Company. Die Maschine wird gemäß der GMP -Anfrage vollständig durchgeführt, Das ist die fortschrittlichste und perfekteste Semesterproduktionsausrüstung.2. Die Maschine ist speziell ausgelegt, um die fortschrittliche Technologie von Übersee gemäß der Kosmetik- und Salbenproduktionstechnologie einzulegen. Die Maschine besteht aus Vorbehandlungskessel, Vakuum -Emulgierung Mischkessel, Vakuumpumpe, Hydrauliksystem und Arbeitstable.3. Die Maschine hat einen einfachen Betrieb, stetige Fähigkeit, Gute Homogenität, hohe Effizienz, Angemessene Struktur, kleines Volumen und hohe Automatisierungsniveau und leicht zu reinigen. Usagept-tthzrj Vakuumemulgierungsmixer ist speziell ausgelegt, um die fortschrittliche Technologie von Übersee gemäß der Kosmetik- und Salbenproduktionstechnologie einzulegen. Die Maschine besteht aus Vorbehandlungskessel, Vakuum -Emulgierung Mischkessel,Vakuumpumpe, Hydrauliksystem und Arbeitstable. Charakteristische Einheit hat Funktionen wie einfachen Betrieb, stabile Leistung, Gute Homogenisierung, hohe Produktionseffizienz, bequeme Reinigung, Angemessene Struktur, kleiner Platz, und hohe Automatisierung usw..

Rührpaddel

Die Geschwindigkeitsregelung mit variabler Frequenz beträgt 0–62 U/min, damit unterschiedliche Materialien gleichmäßig vermischt werden können. Die Form des Mischpaddels wird entsprechend Ihren Materialien gestaltet

Homogenisator

Frequenzumwandlungsgeschwindigkeitsregelung 0-3200 U/min, Homogener Scherkopf, Hochgeschwindigkeits-Schermaterialien, so dass die Materialien vollständig gebrochen und vermischt werden!

Zubehör

Material SS316, Dicke 6 mm,Ausgestattet mit Saugfilter, Abflussventil, Vakuumanschluss, Sichtglaslampe, Sichtglasanschluss mit Schaber, Gewürztrichter, CIP -Reinigung, Air Atemschutzmittel

Öl-Wasser-Topf

Der Wasserphase-Tank und den Ölphase-Tank des Vorbehandlungssystems vorheizen und dispergieren die Rohstoffe, Dann übertragen Sie sie in den Haupttank, und fangen Sie an, homogen zu mischen, um die Materialien zu emulgieren

Konsole

Das Steuerfeld enthält Einstellungen wie homogenes Scheren, Frequenzumwandlungsgeschwindigkeitsregulation Mischung,

Arbeitszeitpunkt, Vakuum -Extraktion, Zwischenschichtheizung, usw.

Arbeitszeitpunkt, Vakuum -Extraktion, Zwischenschichtheizung, usw.

Konsole

Wir werden Zeichnungen entsprechend Ihren Anforderungen entwerfen und One-Stop-Lösungen bereitstellen.

Produkt Konfiguration

Über uns

Erfolgreicher Fallprozess

Zertifizierungen

FAQ

Rezensionen

Es liegen noch keine Bewertungen vor.