Kosmetikcremeproduktion Homogenizer Vakuum Emulgiermischer Salbe für Geräte Lotion Mischmaschine mit Heizung

Produktbeschreibung

Einführen:Struktur:Mischtanks aus Edelstahl werden im Getränk weit verbreitet, Essen, Molkerei, Chemikalie- und Prozessindustrie Gebrauchsmixer Tank, Puffertank und Lagertank, die für sanitäre Standards reinigbar sind .1.Capacity :100-20000L 2. SINGLE -Schicht/ Doppelschichten/ Drei Schichten3.Motorleistung:0.75-5.5KW4.Materialien sind alle Sanitärstahl aus Edelstahl. 5. Humanisierte Strukturdesign und leicht zu bedienen. :1.Schnelles offenes Mannloch .2. Varianische Arten von CIP -Reinigungsmitteln .3.Fly und insektenresistent sanitäre Atembedeckung .4. (Nach Kundenanforderungen ).7.Leiter (Nach Kundenanforderungen).8.Paddelmixer. (Nach Kundenanforderungen) .10.Eddy-Proof-Board .

Rührpaddel

Frequenzumwandlungsgeschwindigkeitsregelung 0-62 U/min, Die Form der Klingen wird entsprechend Ihren Materialien gestaltet.

Homogenisator

Frequenzumwandlungsgeschwindigkeitsregelung 0-3000 U/min, Homogener Scherkopf, Hochgeschwindigkeits-Schermaterialien, so dass die Materialien vollständig gebrochen und vermischt werden!

Öl-Wasser-Topf

Vorbehandlungssystem Wasserphase und Ölphase-Topf zum Vorhitzen und Dispergieren die Rohstoffe, Dann übertragen Sie sie in den Haupttopf, um mit der Produktion zu beginnen.

Hermetisches Vakuum

Die Entschäumung durch das Vakuumsystem kann die Anforderungen an ein aseptisches Produkt mit hohem Standard erfüllen.

Konsole

Das Bedienfeld zeigt und steuert

die Gerätetemperatur, mischen,

Homogenisierung, Druckdaten, usw. in echt

Zeit.

die Gerätetemperatur, mischen,

Homogenisierung, Druckdaten, usw. in echt

Zeit.

Elektrische Box

Nutzen Sie eine international bekannte Marke

Komponenten, um die Qualität der zu gewährleisten

Ausstattung und längere Lebensdauer

Komponenten, um die Qualität der zu gewährleisten

Ausstattung und längere Lebensdauer

Service

Wir entwerfen Zeichnungen nach Ihren Wünschen

Anforderungen und bieten Lösungen aus einer Hand.

Anforderungen und bieten Lösungen aus einer Hand.

Alle Funktionen können nach Ihren Anforderungen angepasst werden.

In der Vergangenheit 26 Jahre, Wir sind mit unseren Kunden zusammengewachsen und haben Benutzern im In- und Ausland professionelle und qualitativ hochwertige Fertigungsgeräte zur Verfügung gestellt.

Sie sind Führer in verschiedenen Bereichen, wie zum Beispiel: Kosmetika, Essen, Chemische Industrie. Wir kümmern uns um jedes Detail des Herstellungsprozesses und haben einen vollständigen und strengen Herstellungsprozess, um erstklassige Geräte zu erstellen.

Wir haben ein professionelles After-Sales-Service-Team, das Ihre Produktion und Ihre Herstellung begleiten kann. Wir setzen die Kundenzufriedenheit und die Produktqualität immer an erster Stelle, Und wir sind fest davon überzeugt, dass wir eine langfristige kooperative Beziehung zueinander haben.

Produkt Konfiguration

Spezifikation

Artikel | Wert |

Mischertyp | Homogenisator |

Fassvolumen (L) | 200 |

Material verarbeitet | Kunststoff, Chemikalien, Essen, Kosmetik |

Max. Ladevolumen (L) | 200L |

Bereich der Spindelgeschwindigkeit(U/min) | 0U/min – 3200U/min |

Gewicht (KG) | 1600KG |

Material | SUS304, Sus316 |

Zustand | Neu |

Produkttyp | Kosmetische chemische Nahrung |

Anwendung | Viskose Flüssigkeit |

Zusätzliche Funktionen | Heizung |

Herkunftsort | China |

Guangdong | |

Markenname | Guanyu |

Stromspannung | |

Leistung (kW) | 7.5kW |

Garantie | 1 Jahr |

Wichtige Verkaufsargumente | Automatisch |

Anwendbare Branchen | Produktionsstätte, Essen & Getränkefabrik, Kosmetische Fabrik, Chemische Industrie |

Standort des Ausstellungsraums | Thailand |

Marketingtyp | Gewöhnliches Produkt |

Maschinenprüfbericht | Bereitgestellt |

Video-Ausgangskontrolle | Bereitgestellt |

Garantie auf Kernkomponenten | 1 Jahr |

Kernkomponenten | Motor, Druckbehälter, Pumpe, SPS, Andere |

Produktname | Vakuum -Emulgier -Mischmaschine |

Maschinentyp | Mischer |

Material | Edelstahl 304 / SUS316L |

Jacke | 3 Schichten 2 Jacken |

Geschwindigkeitskontrolle | Frequenzgeschwindigkeitsregulierung |

Anwendungsbereich | Chemische kosmetische Nahrung |

Rührertyp | Paddelmixer |

Kontrolle | SPS+ Touchscreen |

Heizmethode | Elektrische Dampfheizung |

Besonderheit | Einfacher Betrieb mit hoher Effizienz |

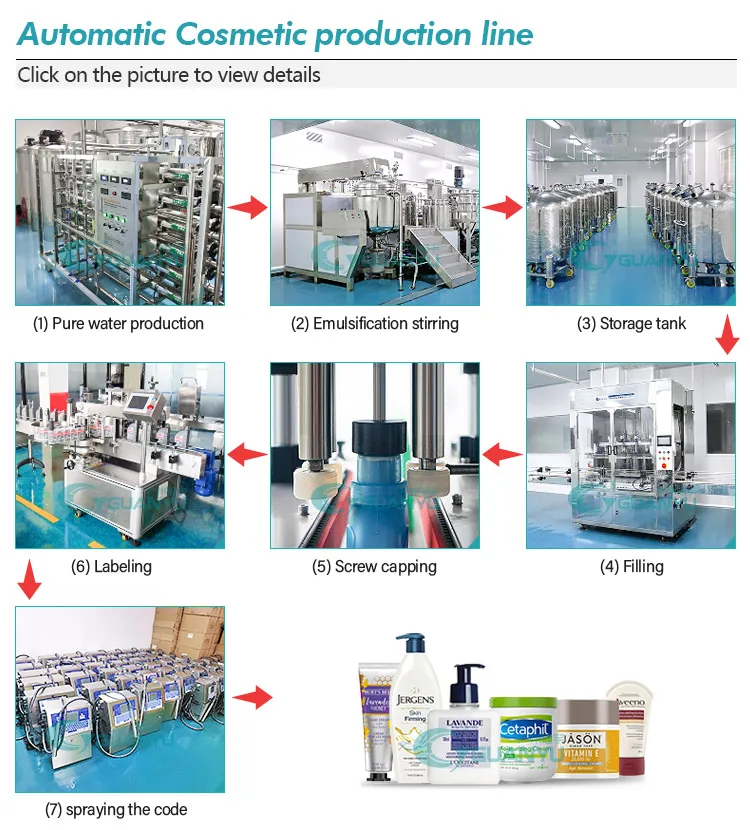

Erfolgreicher Fallprozess

Über uns

Guangzhou Guanyu Machinery Co., GmbH. wurde 1997 gegründet. Es widmet sich in der Entwicklung, Herstellung und Installation des Lebensmittels, Chemikalie, kosmetische und er pharmazeutische Einrichtung und Ausrüstung, Wasserbehandlungsausrüstung und so weiter. Mit der fortschrittlichen Technologie, Produktions- und Inspektionsausrüstung, und die spezialisierten Prozesse. Wir waren ein professioneller Ausrüstungshersteller und stellten Arten der Geräte zur Verfügung, die auf dem Marktanforderungen basieren.

Guangzhou Guanyu Co., Ltd Works hat einen guten Ruf und Vertrauen von Kunden für die rechtzeitige Lieferung erworben, Zuverlässige Qualität und gute After-Sales-Service. Wir führen zuerst ein festes Prinzip der Einhaltung von Verträgen und Qualitätsqualität” In der Zwischenzeit, Wir nehmen Kunden immer als oberste Sorge und bemühen uns, ihnen gut zu dienen.

Für die Befriedigung der inländischen und internationalen Kunden, Wir halten unser Prinzip fest “Qualität die erste, Technologie -Führung, Sozial- und Umweltpflege und kontinuierliche Entwicklung ” um die Kriterien des ISO9001 zu erfüllen, und gut danach- hat uns einen guten Ruf in der Branche besitz.

Wir begrüßen die Kunden im In- und Ausland herzlich, um unser Unternehmen zu besuchen und unsere Produkte zu wählen!

Guangzhou Guanyu Co., Ltd Works hat einen guten Ruf und Vertrauen von Kunden für die rechtzeitige Lieferung erworben, Zuverlässige Qualität und gute After-Sales-Service. Wir führen zuerst ein festes Prinzip der Einhaltung von Verträgen und Qualitätsqualität” In der Zwischenzeit, Wir nehmen Kunden immer als oberste Sorge und bemühen uns, ihnen gut zu dienen.

Für die Befriedigung der inländischen und internationalen Kunden, Wir halten unser Prinzip fest “Qualität die erste, Technologie -Führung, Sozial- und Umweltpflege und kontinuierliche Entwicklung ” um die Kriterien des ISO9001 zu erfüllen, und gut danach- hat uns einen guten Ruf in der Branche besitz.

Wir begrüßen die Kunden im In- und Ausland herzlich, um unser Unternehmen zu besuchen und unsere Produkte zu wählen!

Verpackung & Lieferung

Nachdem die Ausrüstung inspiziert und getestet wurde, Unser After-Sales-Team packt die Ausrüstung in Holzkisten, um sicherzustellen.

Zertifizierungen

FAQ

1.Sind Sie eine Fabrik??

A: Ja, wir sind eine Fabrik mit mehr als 23 Jahre Erfahrung in der Herstellung. Einer davon befindet sich in der Provinz Jiangsu, Ein anderer ist in Guangzhou neben unserem Büro.2. Ich bin neu in unserer Branche,Aber ich plane, eine Fabrik einzurichten, was kann ich tun?A:Wir werden den am besten geeigneten Vorschlag auf der Grundlage Ihrer tatsächlichen Situation wie der täglichen Produktion entwerfen, Rohstoffformel,Fabriklayout usw.. Außerdem möchten wir einige hervorragende Lieferanten von Rohstoffen vorstellen,Flaschen. Etiketten. usw, falls erforderlich. Nach dem Verkaufsingenieur wird an Fields Installation Training und Inbetriebnahme gesendet.3.Wie lang ist Ihre Garantie?Nach der Garantie was ist, wenn wir auf ein Problem mit der Maschine stoßen?A: Unsere Garantie beträgt ein Jahr. Nach der Garantie bieten wir Ihnen weiterhin einen lebenslangen Kundendienst,Wann immer Sie es brauchen, sind wir für Sie da. Wenn das Problem leicht zu lösen ist, werden wir ein Lösungsvideo für Sie aufnehmen. Wenn das Video nicht funktioniert?A: Erste,Unsere Komponenten-/Ersatzteile -Anbieter testen ihre Produkte, bevor sie uns Komponenten anbieten. Außerdem, Unser Qualitätskontrollteam testet die Leistung oder Laufgeschwindigkeit der Maschine vor dem Versand. Wir möchten Sie einladen, in unsere Fabrik zu kommen, um die Maschinen selbst zu überprüfen. Wenn Ihr Zeitplan beschäftigt ist, Wir werden ein Video aufnehmen, um den Testprozedur aufzuzeichnen und das Video an Sie zu senden.5. Sind Ihre Maschinen schwer zu bedienen? Wie bringen Sie uns den Umgang mit der Maschine bei??A: Unsere Maschinen sind ein Operationsdesign im Narrenstil sehr einfach zu bedienen. Außerdem werden wir vor der Lieferung ein Anweisungsvideo aufnehmen, um Maschinenfunktionen einzuführen und Ihnen beizubringen, wie man sie benutzt. Bei Bedarf stehen Ingenieure zur Verfügung, um in Ihre Fabrik zu gelangen, um Maschinen -Testmaschinen zu installieren und Ihren Mitarbeitern beizubringen, die Maschinen zu benutzen?A: Ja, Kunden sind herzlich eingeladen, unsere Fabrik zu besuchen.?A: Ja, OEM ist akzeptabel. Die meisten unserer Maschinen sind kundenspezifische Designs, die auf den Anforderungen oder der Situation des Kunden basieren.

Rezensionen

Es liegen noch keine Bewertungen vor.