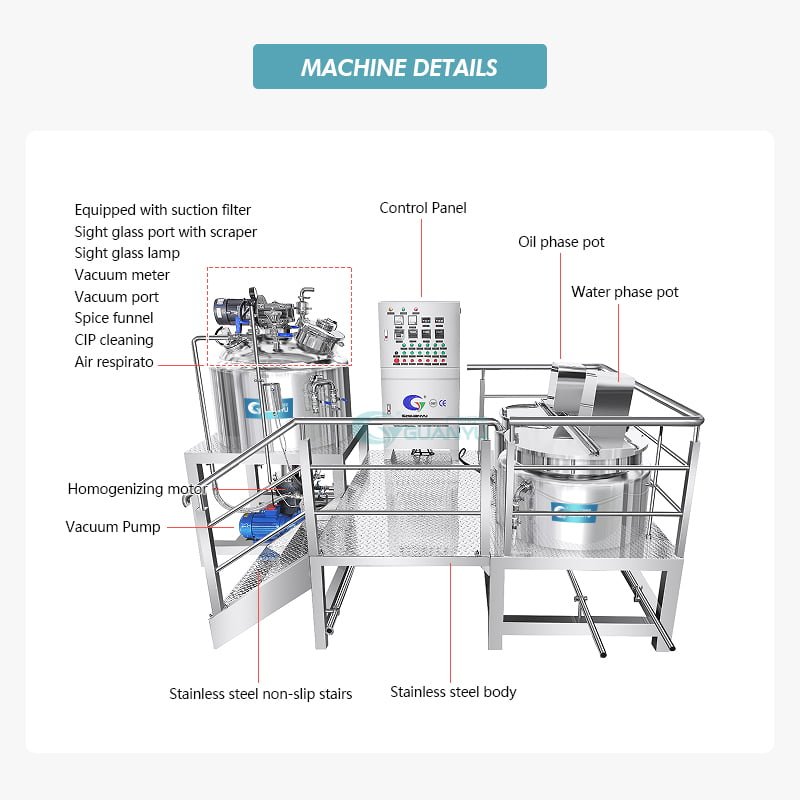

High Level Stainless Steel Fixed Ointment cream emulsifier homogenizer

Modell | Volumen (L) | Mischkraft (kw) | Rotationsgeschwindigkeit des Mixers (U/min) | Homogenisierende Kraft(kw) | Homogenisierende Rotationsgeschwindigkeit(U/min) | Heizmethode |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Dampfheizung oder Elektroheizung |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

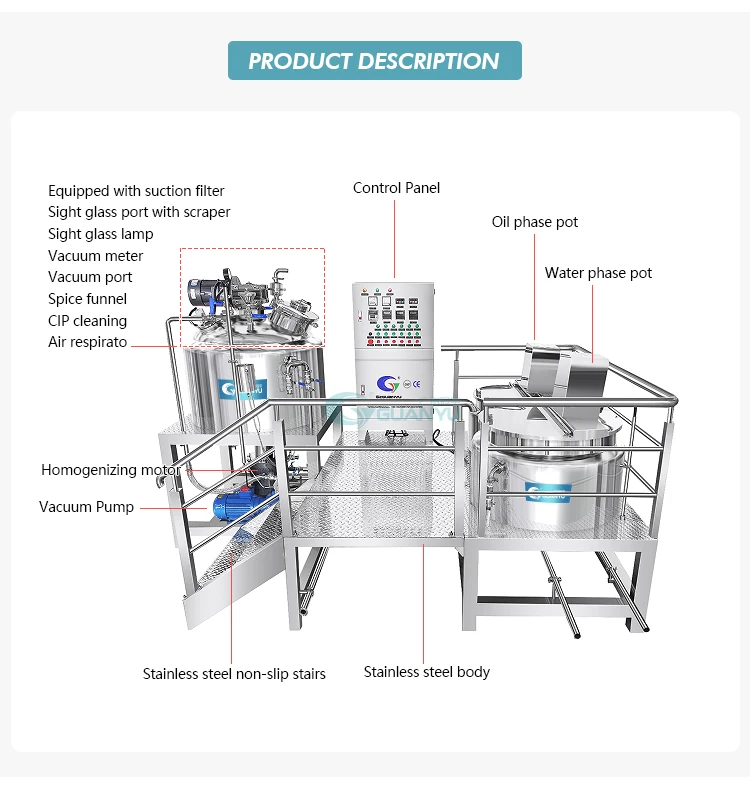

2, The homogenizing structure is made through German technology. The machine adopts the imported double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 3600 rpm and the high shearing fineness can reach 0.2-5 eins.

3, The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4, The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

5, The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish which meet the GMP standard.

6, According to process requirement, the tank body can heating and cooling the electric heating.

7, To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

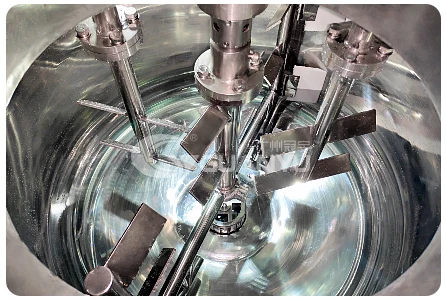

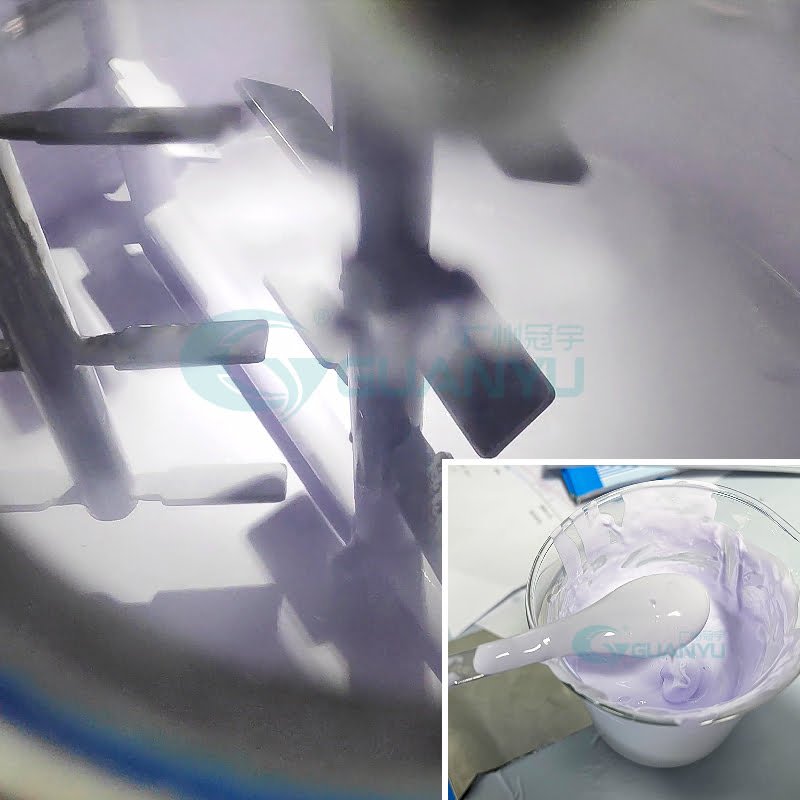

Rührpaddel

Homogenisator

Frequenzumwandlungsgeschwindigkeitsregelung 0-3200 U/min, Homogener Scherkopf, Hochgeschwindigkeits-Schermaterialien, so dass die Materialien vollständig gebrochen und vermischt werden!

Oil-water pot

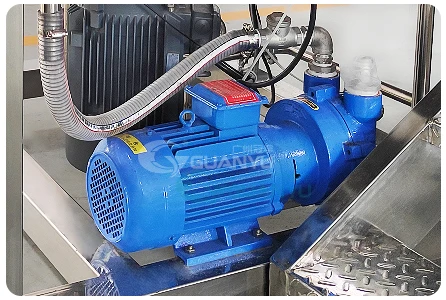

Vacuum Pumps

Konsole

working timing, vacuum extraction, interlayer heating, usw.

(PLC control is optional)

Service

Verwenden Sie international bekannte Markenkomponenten, um die Qualität der Geräte und eine längere Lebensdauer zu gewährleisten

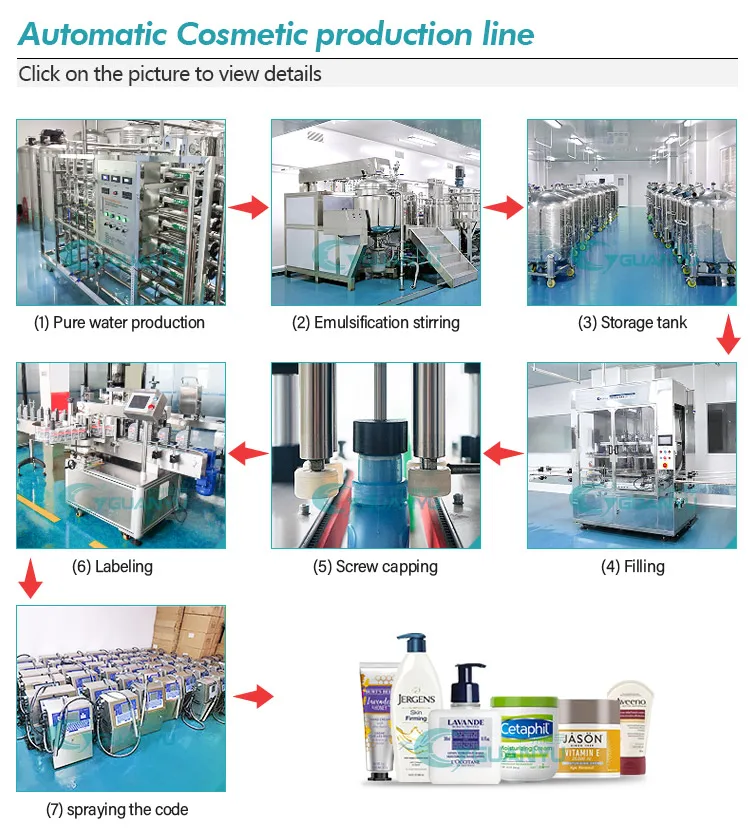

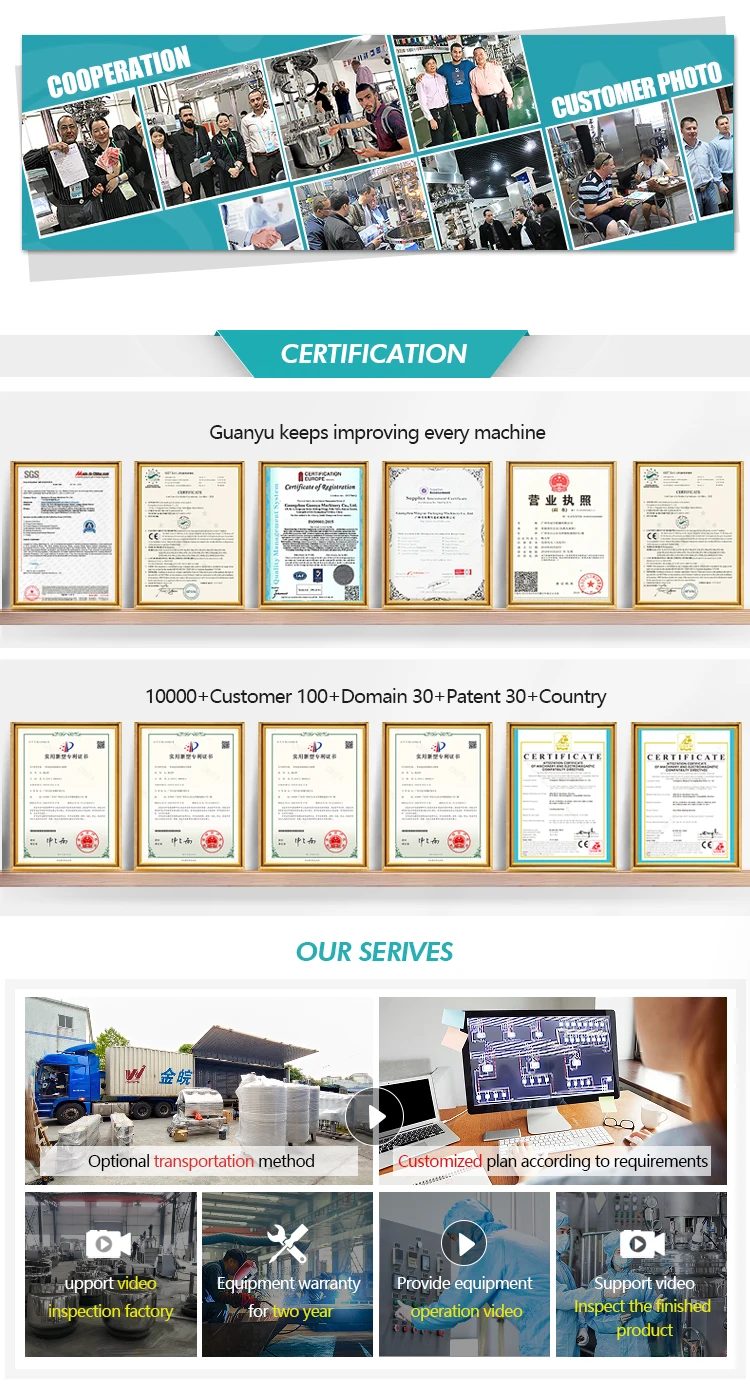

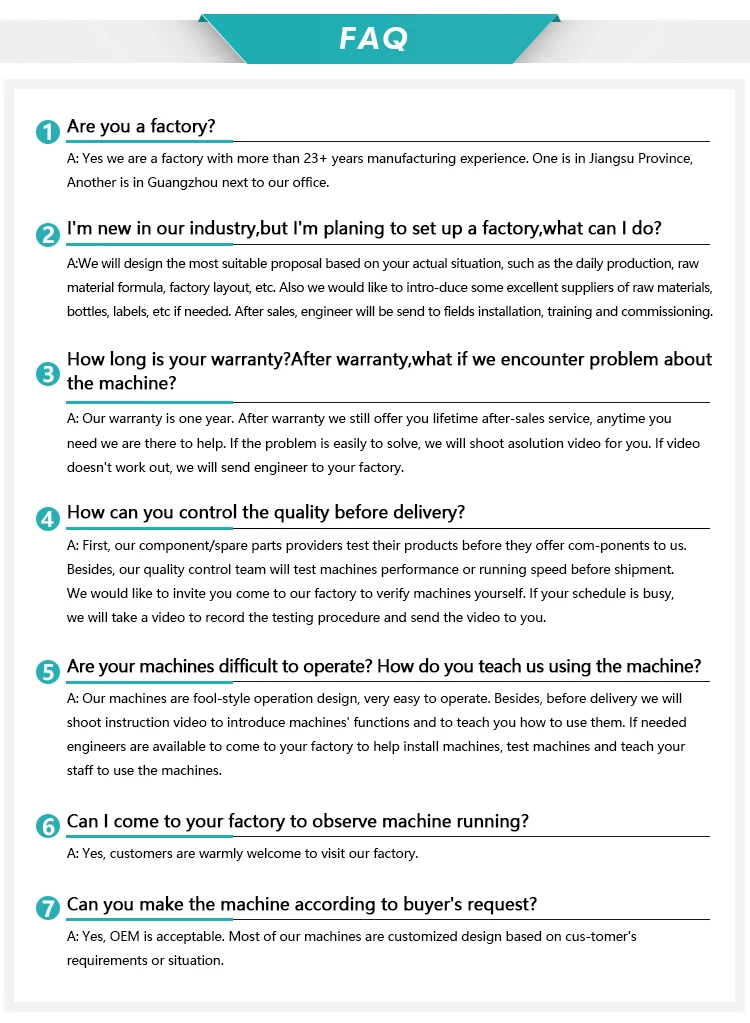

We specialize in the development and manufacturing of leading cosmetic, food production equipment and production lines, and sincerely provide the best quality and service to each customer:

1. One-Stop-Lösung

With German FLUKO and IKA as the technical core, we provide an overall solution of “consulting + equipment customization + engineering installation” to help many well-known domestic and foreign companies achieve production goals. It has the most complete end-to-end production line in the machinery industry, which can flexibly meet the differentiated needs of different manufacturers and customers around the world and the pursuit of rapid innovation.

2. Company advantages

Guanyu Machinery Company was established in 1997 and is committed to the development, manufacturing and installation of cosmetics, food industrial equipment. With our advanced technological production and testing equipment and specialized process flow, we have become a professional equipment manufacturer and provide a variety of equipment and solutions according to customers’ special needs.

3. Customized machines

(1) Vacuum emulsifier homogenizer mixer

(2) Opened mixing tank blender stirring machine

(3) Filling capping labeling machine packaging machine

(4) RO reverse osmosis water treatment

(5) Multiple types of storage tanks

Typ: vacuum seal/open, fixed/mobile/hydraulic lifting

Heizmethode: steam heating or electric heating

Contact material: Edelstahl 304/316

Kapazität: 50L, 100L, 500L, 1000L, 2000L, 5000L, usw.

Applicable voltage: 220V/380V, usw.

Structure: single layer/3 layers

Stirring speed: 0-63Drehzahl (variable frequency adjustment)

Homogenization speed: 0-3600Drehzahl

4. Applicable products

Creme, Lotion, facial cleanser, essential oil, Waschmittel, shower gel, Shampoo, Parfüm, spray, emulsify, Ointment etc.

Anonym –

Cost-effective with a remarkable performance. Definitely recommend this product.

Jerold –

I always used to read piece of writing in news papers

but now as I am a user of net so from now I am

using net for articles or reviews, thanks

to web.!

Mitzi –

Hi! Do you know if they make any plugins to assist with Search Engine Optimization? I’m trying to get my website

to rank for some targeted keywords but I’m not seeing very

good gains. Wenn Sie etwas wissen, teilen Sie es bitte mit. Many thanks!

You can read similar art here: Öko-Produkt

Lamentos –

Dinle: Bırak Bu Film Ağızlarını Türkçe Rap Beat

Ask Travel Italy –

This article was both educational and enjoyable to read. It’s one of the best resources I’ve come across on sustainable travel. We talked about a similar topic on TravelForums. I’m excited to see more of your work—thank you!

m3 insert –

pirinç somun pirinç somun. Altınkaya.

Miguel –

Hi there! Do you know if they make any plugins to help with

Search Engine Optimization? I’m trying to get my

site to rank for some targeted keywords but I’m not seeing very good success.

Wenn Sie etwas wissen, teilen Sie es bitte mit. Many thanks! You can read similar blog

here: Change your life

esenyurt avukat –

en kaliteli çakma somun çakma somun. Altınkaya.

Carley –

I am really impressed along with your writing skills and also with the format for your weblog. Is that this a paid theme or did you customize it yourself? Either way stay up the nice quality writing, it is uncommon to see a nice blog like this one nowadays. I like guanyumixer.com ! It’s my: Madgicx

Fabian –

I am extremely inspired with your writing skills as smartly as with the format on your blog. Is that this a paid subject or did you customize it your self? Anyway stay up the excellent quality writing, it is rare to look a nice weblog like this one nowadays. I like guanyumixer.com ! My is: Beehiiv

ruhların etiketi spotify –

en iyi rap beat albüm Ruhların Etiketi Spotify. Lamentos