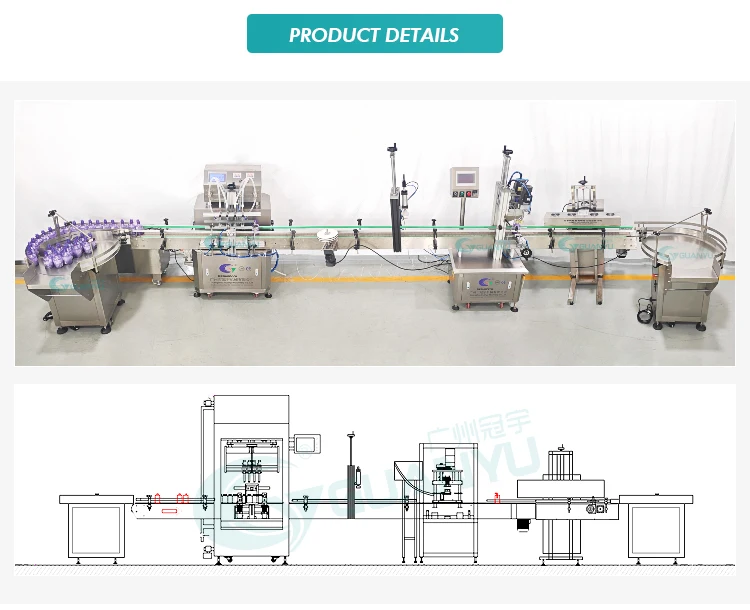

Aufschlag | Alle Geräte der Produktionslinie können nach den Kundenanforderungen angepasst werden |

Maximale Füllgeschwindigkeit | Füllung von 200 ml, 2000~ 3000 PCs/Stunde, Die Geschwindigkeit ist unterschiedlich, wenn die Flaschenform und die Nackengröße sowie das Füllmaterial und die andere physische Eigenschaft bilden |

Anwendbarer Flaschendurchmesser Größe | 30-300(Mm) |

Anwendbare Flaschenhöhe Größe Größe | 30-400(Mm) |

Dosis füllen | 500 ~ 5000 ml (anpassbar) |

Füllgenauigkeit | ± 1% |

Stromspannung | 110V ~ 680v, kann angepasst werden |

Legen Sie die Flasche | Flaschenabskrambler automatische Flaschenfreisetzung |

Arbeitsdruck | 0.4 – 0.6MPa |

Programmkontrolle | SPS+Touchscreen Man-Maschine-Schnittstelle |

Capping -Geschwindigkeit | 2000-3000 Flaschen/Stunde |

Niedrigerer Deckungsweg | Manuelle oder vibrierende Platte |

Versiegelt | Bei Bedarf können Aluminiumfolienversiegelung hinzugefügt werden |

Hauptmerkmale (Flasche Unscrambler):

1、Geeignet für die automatische Flaschenabteilung und automatische Übertragung von runden und quadratischen Flaschen, kompatibel mit Plastik und Glasbehl,

4、Der Durchmesser der anwendbaren Flasche kann frei eingestellt werden, und es ist mit Schälenflaschen und Plastikflaschen kompatibel. Die Flasche Fördergeschwindigkeit beträgt 30 ~ 200 Flaschen/min. Die Geschwindigkeit kann schrittweise eingestellt werden, das ist praktisch für die Produktionsanordnung.

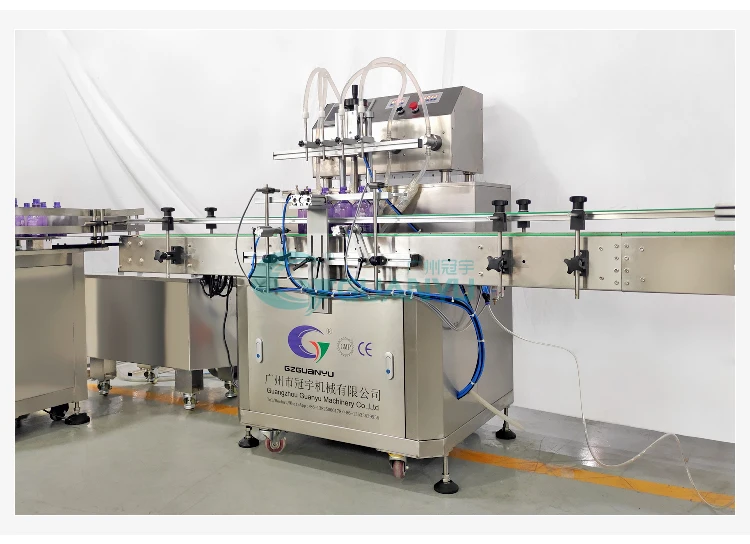

Hauptmerkmale (Füllmaschine):

1、Die Ausrüstung hat eine starke Kompatibilität, und kann schnell Flaschen mit verschiedenen Formen und Spezifikationen einstellen und ersetzen, wobei Teile ersetzt werden, Dies kann die Produktionsanforderungen mehrerer Sorten und Spezifikationen entsprechen

2、SPS -Kontrolle ,Flaschenbetrieb berühren ,Einfacher und bequemer Betrieb.

3、Die Verwendung von elektrischen Komponenten der Internatioal Famouse Brand, Leistung und Stabilität.

4、Der Benutzer kann den Füllbereich einstellen, Die Materialien sind in Hopper nicht ausreichend, Der Computer gibt das Signal der Fütterungspumpe an

AddMaterial nach Levelsensor. Wenn das Material voll ist, Die Pumpe stoppt automatisch.

5、Maschinenbehörde wird hergestellt von 304 Edelstahl, leicht zu reinigen, Die Maschine entspricht vollständige Einhaltung der GMP -Anforderungen.

6、Peristaltisches Pumpen- oder Kolbenpumpenfüllsystem, Präzision messen, bequeme Manipulation.

Hauptmerkmale (Capping Machine):

1、Der CAP -Aufzug und die Vibrationsfutterheime können gemäß der Form der Kappe und der Art der Kappe ausgewählt werden

2.、Schnelle Verschlüsselungsgeschwindigkeit, einstellbar von 0-45 Flaschen/min

3.、Flaschen und Kappen verschiedener Größen können eine Maschine teilen, indem einige Zubehör angepasst oder geändert werden

4.、Der Tankkörper der Ausrüstung dreht sich nicht, wenn die Kappe geschraubt ist, was die Verschiebung vermeidet, Streuung und mögliche Beschädigung der im Tank enthaltenen Produkte.

5、die für eine unterschiedliche Kappe in unterschiedlichen Materialien und unterschiedlichen Spezifikationen angewendet wurden.

6、die mit 3-Roller-Capping-Messer mit 3-Roller-Typ verwendet werden ,Es ist leicht, den Druck zu regulieren.

7、die auf Metallkappe aufgetragen wurden ,Schraubenkappe , Pilfer-ProofCap, Kompressionskappe, usw…

Hauptmerkmale (Aluminiumfolie -Dichtungsmaschine):

1、Die Aluminiumfolienversiegelungsmaschine wird hauptsächlich zum Erhitzen und Versiegeln der Versiegelung des Verbundfilmmaterials und der Plastikbeutelversiegelung mit Polyolefin verwendet (wie Polyethylen, Polypropylen, usw.) als innere Schicht.

2、Die Dicke der Aluminiumfolie und der Durchmesser der Dichtung können in einem bestimmten Bereich aufgetragen werden, und ein gutes und gleichmäßiges lineares Siegel kann erreicht werden.

3、Egal große Flasche, kleine Flasche, Lange Flasche oder kurze Flasche kann kontinuierlich versiegelt werden

4、Alle Heizteile der Maschine verwenden luftgekühlte erzwungene Kühltechnologie, Dies senkt die Herstellungskosten stark und miniaturisiert die Ausrüstung.

Rezensionen

Es liegen noch keine Bewertungen vor.