Vacuum Emulsifier Mixer used for produce cream, Lotion, Salbe, Haarspülung, hair color cream, Gel usw..

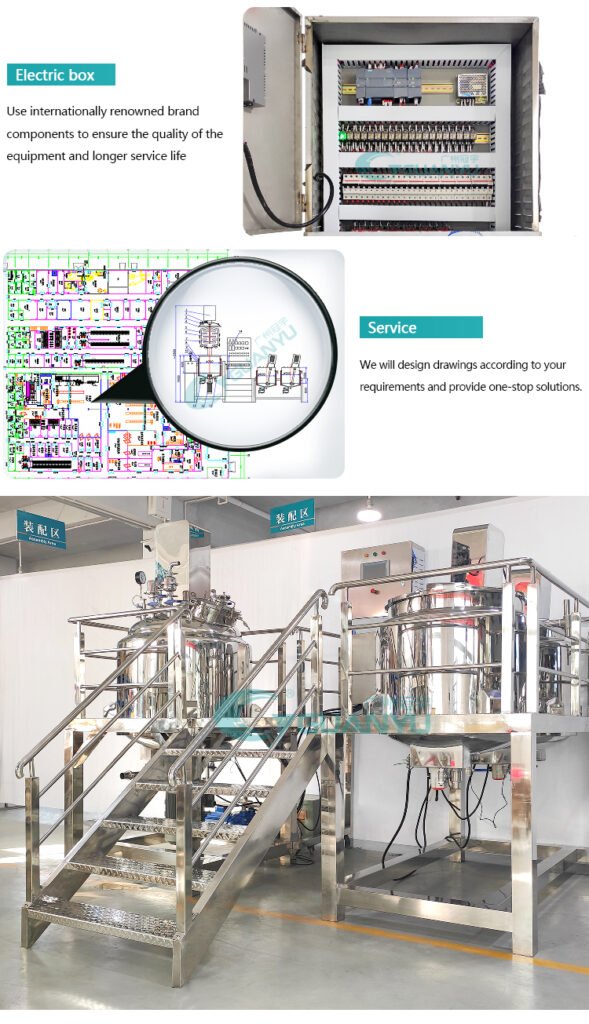

1.Continuous working processing quantity is big and it can produce material circularly and homogenized and also can put positive pressure to produce material on main boiler which is convenient and fast;

2.Easy to operate and has better homogenizing emulsifying effect.

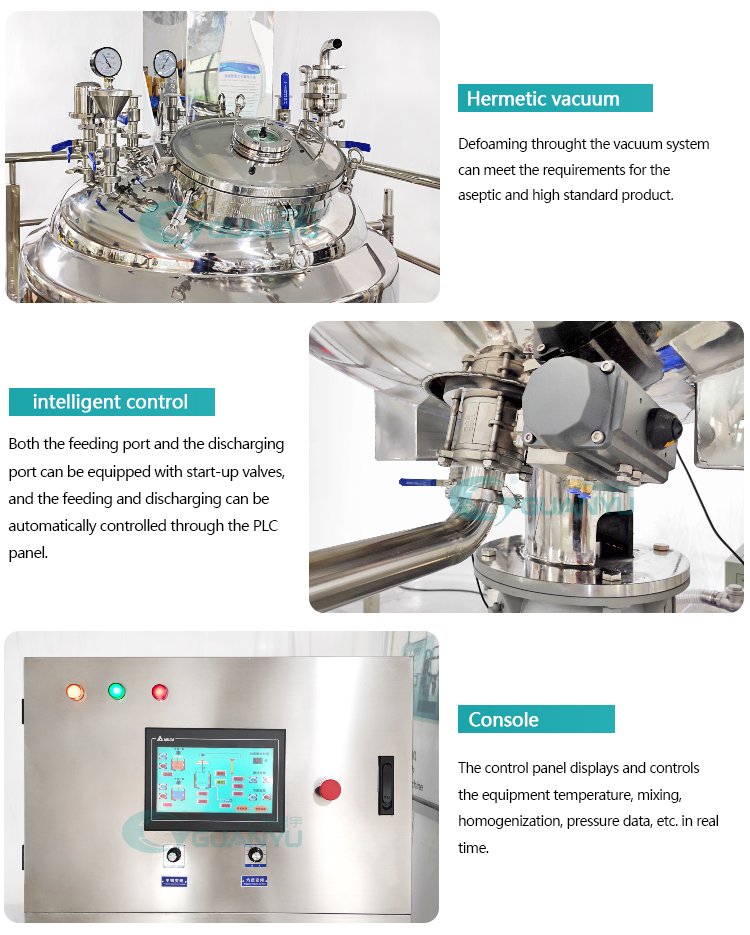

3.Water circle homogenizing airproof structure of England Cran Company conquers common airproof leaking problem; sealing ring can’t be burnt under high viscosity and non-material condition.

4.CIP cleaning system is configured through outside circle pipe to make emulsifying machine cleaned automatically, conveniently, wholesomely and thoroughly.

Body Lotion Shampoo Liquid Soap Making Machines Vacuum Homogenizing Emulsifier Mixer Machine

What is the difference between a “Vacuum Emulsifier Mixer” and a “Planetary Mixer”?

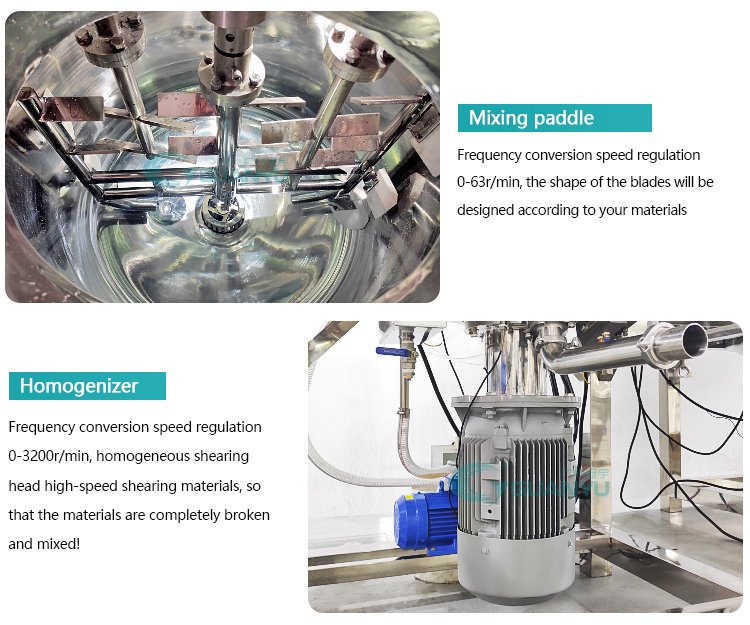

Ⅰ 【Ordinary Emulsifier】The rotor stator is generally made of high-strength cemented carbide, similar to two grinding discs for shearing motion, which is relatively wear-resistant, and the emulsification effect can be achieved by adjusting the gap.

√ The advantage is that the mixing effect is good, choosing the appropriate emulsification head can be applied to a variety of working conditions, widely used, and suitable for a variety of different industries;

× The disadvantage is that the output is low, and the mixing effect is poor for hard particle materials and high viscosity materials.

Ⅱ 【Vacuum Emulsifier】It is mainly used for mixing two liquid substances, but it is not suitable for mixing solid and liquid substances. Because most of the homogenizers are of the plunger type, the solid particles will cause friction to the plunger, and the particles will be stuck at the one-way valve, which will reduce the homogenization effect.

√ The advantage is that the mixing effect is good;

× Disadvantages are high power consumption, low output, prone to failure, and high maintenance costs.

Ⅲ 【Planetary Mixer】It is mainly used in simple mixing, such as the material itself does not need to be refined, just simple mixing;

√ The advantage is that the traditional stirring method has large output and wide application;

× The disadvantage is that there is no shear thinning effect on the material, and only simple mixing can be performed.

Aufführungen und Funktionen

The continuous working capacity is large, and the material can be circulated and homogeneously discharged. It is especially suitable for the continuous processing of single varieties of products.

Ihr Artikel hat mir sehr geholfen, Gibt es weitere verwandte Inhalte?? Danke!

Ihre Sichtweise ist mir aufgefallen und sehr interessant. Danke. Ich habe eine Frage an Sie.