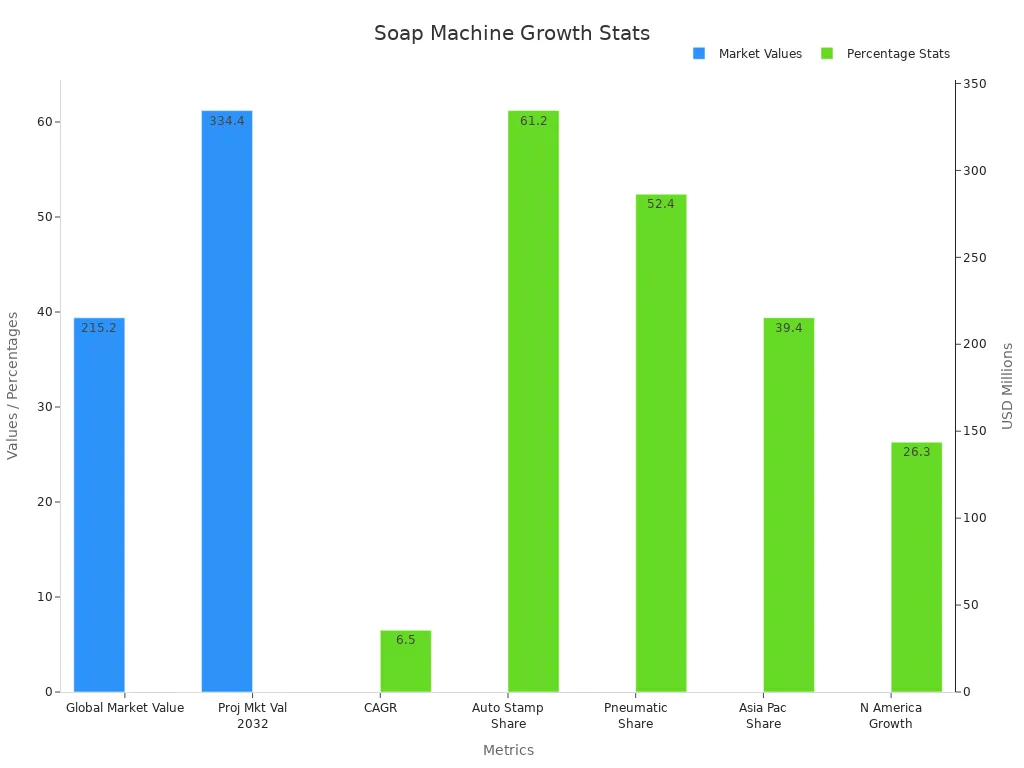

Auswahl der richtigen Seifenherstellungsmaschine zum Verkauf in 2025 hilft Ihnen, Ihre Geschäftsziele zu erreichen. Sie müssen sich die Art der Seife ansehen, die Sie herstellen möchten, wie viel Sie produzieren möchten, und was Ihre Kunden erwarten. Die Auswahl einer Maschine, die Ihren Anforderungen entspricht, steigert Ihre Effizienz und Produktqualität. Die Zahlen sagen alles – automatische Maschinen machen das aus 61.2% des Marktes weil sie Unternehmen helfen, schneller zu wachsen. Wenn Sie sehen möchten, wie stark die Branche wächst, Schauen Sie sich diese Tabelle an:

Nehmen Sie sich Zeit und befolgen Sie jeden Schritt. Die richtige Wahl bereitet Sie auf langfristigen Erfolg vor.

Key Takeaways

Wählen Sie eine Seifenmaschine, die zu Ihrer Seifensorte passt, wie Riegel oder Flüssigkeit. Dadurch sparen Sie Zeit und Geld.

Wählen Sie eine Maschinengröße, die zu Ihrer täglichen Seifenmenge passt. Stellen Sie sicher, dass es mehr aushält, wenn Ihr Unternehmen wächst.

Finden Sie Maschinen mit gute Automatisierung und Mischung. Diese Funktionen helfen Ihnen, schneller bessere Seife herzustellen und weniger Abfall zu verschwenden.

Denken Sie darüber nach Maschinen, die weniger Energie verbrauchen und sind besser für die Umwelt. Dies kann Ihnen auch dabei helfen, weniger Geld auszugeben.

Kaufen Sie bei einem vertrauenswürdigen Lieferanten, der guten Support bietet. Sie sollten schnelle Ersatzteile und starke Garantien bieten. Dadurch bleibt Ihr Unternehmen gut am Laufen.

Definieren Sie Ihren Seifentyp

Sie sollten zunächst wissen, welche Art von Seife Sie herstellen möchten. Diese Wahl wirkt sich auf alles andere aus, was Sie tun. Manche Maschinen funktionieren nur mit bestimmten Seifen. Wenn Sie jetzt den richtigen Typ auswählen, Sie sparen später Zeit und Geld.

Bar vs. Flüssigseife

Stückseife und Flüssigseife benötigen unterschiedliche Maschinen. Seifenstückmaschinen arbeiten mit fester Seife. Sie benutzen Verseifungsreaktoren, Trockner, Fräser, und Stempel. Diese Maschinen formen, schneiden, und stempeln Sie jeden Riegel. Flüssigseifenmaschinen mischen, füllen, und verpacken Sie die Seife. Sie nutzen intelligente Sensoren und Automatisierung, um den Prozess zu steuern. So erhalten Sie jedes Mal die richtige Formel und eine reibungslose Füllung.

Hier ist ein kurzer Blick darauf, wie der Markt für Stückseife wächst:

Aspekt | Details |

|---|---|

Wachstumsrate | Der Markt für Stückseifen wächst mit einer jährlichen Wachstumsrate von 4.43% aus 2024 Zu 2032 |

Schlüsselfaktoren | Immer mehr Menschen in Hotels und Haushalten wünschen sich Stückseife, insbesondere im asiatisch-pazifischen Raum |

Verbraucherpräferenz | Die Menschen wünschen sich natürliche und biologische Seifen, die dazu beitragen, die Haut weich zu halten |

Regionalleiter | Der asiatisch-pazifische Raum führt mit 33.99% Marktanteil aufgrund von mehr Menschen und Städten |

Qualitätssegment | Am beliebtesten sind Seifen in Standardqualität, da sie günstiger sind und häufig verwendet werden |

Auch Flüssigseife wird immer beliebter. Die Leute wollen Seifen, die es sind organisch und ohne aggressive Chemikalien. Unternehmen nutzen recycelbare Verpackungen und Nachfüllkartons, um weniger Müll zu produzieren. Viele Menschen mögen Flüssigseife zum Händewaschen, weil sie denken, sie sei sauberer als Stückseife.

Flüssigseifenmaschinen Mischen und füllen Sie die Seife sorgfältig ein.

Für die Verpackung werden Materialien verwendet, die recycelt werden können.

Viele Marken verkaufen sulfatfreie und parabenfreie Seifen.

Spezial- und kundenspezifische Seifen

Möchten Sie spezielle Seifen herstellen?? Vielleicht möchten Sie Bio herstellen, Kräuter-, oder individuell geformte Stangen. Bei einigen Maschinen können Sie Farben hinzufügen, Düfte, oder besondere Zutaten. Andere können andere Formen herstellen oder Ihr Logo auf der Seife anbringen. Wenn Sie möchten, dass Ihre Seife anders ist, Pick-Maschinen mit zusätzlichen Funktionen. Dies hilft Ihnen, neue Trends zu verfolgen und Ihre Marke auszubauen.

Passen Sie den Produktionsmaßstab an

Klein, Medium, Große Operationen

Sie müssen darüber nachdenken, wie viel Seife Sie jeden Tag herstellen möchten. Du fängst gerade erst an, oder haben Sie bereits viele Bestellungen? Vielleicht betreiben Sie einen kleinen Laden, oder vielleicht beliefern Sie große Geschäfte. Die Größe Ihres Unternehmens hilft Ihnen bei der Auswahl richtige Maschine.

Kleine Operationen machen normalerweise weniger als 100 Kilogramm Seife pro Tag. Sie können eine Kompaktdose verwenden, Handbuch, oder halbautomatische Maschine. Diese Maschinen kosten weniger und nehmen weniger Platz ein. Sie können sie sogar in einer kleinen Werkstatt oder Garage aufstellen.

Mittlere Operationen dazwischen machen 100 Und 500 Kilogramm pro Tag. Möglicherweise benötigen Sie eine größere Maschine mit mehr Funktionen. Automatische Maschinen helfen Ihnen, Zeit zu sparen und die Qualität Ihrer Seife immer gleich zu halten.

Große Operationen überarbeiten 500 Kilogramm pro Tag. Sie benötigen eine hohe Kapazität, Vollautomatische Maschine. Diese Maschinen arbeiten schnell und können den ganzen Tag laufen. Außerdem benötigen sie mehr Platz und Leistung.

Tipp: Notieren Sie Ihre durchschnittlichen täglichen oder wöchentlichen Seifenbestellungen. Diese Nummer hilft Ihnen bei der Entscheidung, welche Maschinengröße Ihren Anforderungen entspricht.

Raum für Skalierung

Sie könnten klein anfangen, Aber Ihr Unternehmen kann wachsen. Es ist klug, sich für eine Maschine zu entscheiden, mit der Sie später mehr Seife herstellen können. Bei einigen Maschinen können Sie zusätzliche Teile hinzufügen oder auf ein größeres Modell aufrüsten.

Suchen Sie nach Maschinen mit modularem Aufbau. Sie können Mixer hinzufügen, Fräser, oder zusätzliche Formen, wenn Ihre Bestellungen zunehmen.

Fragen Sie den Lieferanten, ob Sie die Maschine in Zukunft aufrüsten können.

Prüfen Sie, ob die Maschine verschiedene Rezepte oder Seifenarten verarbeiten kann.

Durch die Planung Ihres Wachstums sparen Sie Geld und Zeit. Wenn Ihr Unternehmen größer wird, müssen Sie keine komplett neue Maschine kaufen.

Jetzt die richtige Größe auswählen, mit Raum zum Wachsen, hilft Ihrem Unternehmen, flexibel und bereit für neue Möglichkeiten zu bleiben.

Zu berücksichtigende Hauptmerkmale

Wenn Sie sich für eine Seifenmaschine entscheiden, Sie wollen mehr als nur etwas, das funktioniert. Sie möchten eine Maschine, die Ihrem Unternehmen hilft, besser zu werden, spart Geld, und bleibt mit neuen Ideen auf dem Laufenden. Hier sind die wichtigsten Dinge, auf die Sie achten sollten.

Automatisierungsstufe

Automatisierung kann die Seifenherstellung erheblich erleichtern. Mit der richtigen Automatisierung können Sie schneller und mit weniger Fehlern mehr Seife herstellen. Viele neue Maschinen verwenden SPS-Steuerungen und Touchscreens. Damit können Sie Rezepte festlegen, Kontrollschritte, und beobachten Sie, was passiert, während Sie arbeiten. Bei einigen Maschinen können Sie sie sogar von Ihrem Telefon oder Computer aus überprüfen.

SPS-Steuerungen und Touchscreens helfen Ihnen, mehr Schritte automatisch auszuführen, Sparen Sie Geld für die Arbeiter, und weniger Fehler machen.

Die Vakuummischtechnologie entfernt Luftblasen und Schaum, So wird Ihre Seife glatter.

Energiesparende Designs verbrauchen beim Mischen und Erhitzen weniger Strom.

Sie können die Geschwindigkeit und Temperatur ändern, um bessere Seife zu erhalten.

Edelstahlteile und klare Designs schützen Ihre Seife.

Sie können kleine oder große Mengen herstellen, je nachdem, was Sie brauchen.

Automatisierung und Roboter helfen Ihnen, Seife schneller herzustellen und weniger Geld auszugeben.

Mit IoT und intelligenten Funktionen können Sie Ihre Maschine überwachen, Plankorrekturen, und stoppen Sie Probleme, bevor sie beginnen.

Hochgeschwindigkeits-Servosysteme kann jede Stunde jede Menge Seifen stempeln und das sehr gut.

Modulare und kleine Designs sparen Platz und ermöglichen das spätere Hinzufügen neuer Dinge.

Wenn Sie möchten, dass Ihr Unternehmen wächst, Automatisierung ist sehr hilfreich. Damit können Sie mehr Seife herstellen, mach weiter so, und weniger für die Arbeiter bezahlen.

Misch- und Formfunktionen

Mischen und Formen sind bei der Seifenherstellung sehr wichtig. Sie benötigen eine Maschine, die alles gut mischt und Ihre Seife so formt, wie Sie es möchten. Eine gute Mischung bedeutet, dass jeder Riegel oder jede Flasche gleich ist. Durch eine gute Form sieht Ihre Seife schön aus.

Hier ist ein kurzer Blick auf die Funktionsweise neuer Maschinen:

Leistungsmetrik | Wert | Was es bedeutet |

|---|---|---|

Trocknungskapazität | Wie viel Seife trocknet in einer Charge? | |

Trocknungszeit | 15.5 Minuten | Wie lange dauert es, Seife zu trocknen? |

Trocknungseffizienz | 83.4% | Wie gut trocknet die Maschine Seife? |

Trocknungsgeschwindigkeit | 2.13 kg Wasser/Min | Wie schnell verlässt Wasser die Seife? |

Entladungseffizienz | 77.1% | Wie viel Trockenseife kommt heraus? |

Materialverschwendung | 1.31% | Wie viel Seife geht verloren? |

Maschinenkapazität | ~560 kg/h | Wie viel Seife können Sie in einer Stunde herstellen? |

Mechanischer Stress (von Mises) | 51.475 MPa | Die Maschinenteile sind stabil und sicher |

Feuchtigkeitsgleichmäßigkeit | Geringe Variation | Jede Charge wird gleich gemischt und getrocknet |

Maschinen wie die Crutcher-Vertikalmischer Verwenden Sie eine starke Schraube, um alles gut zu vermischen. Eine Ankerklinge kratzt am Boden, sodass nichts kleben bleibt. Sie können diese Maschinen mit normalem oder hohem Druck verwenden, und einige verfügen über Wägezellen, um Zutaten genau zu messen. Mit einer Stampfmaschine wird die Seife zu Bändern geformt, und Schneidetische schneiden Stangen auf die richtige Größe. Diese Schritte stellen sicher, dass Ihre Seife jedes Mal gleich aussieht und sich gleich anfühlt.

Wenn Sie sich für eine Maschine mit guter Misch- und Formleistung entscheiden, Ihre Seife wird schön aussehen und gut funktionieren. Ihre Kunden werden den Unterschied sehen.

Nachhaltigkeitsoptionen

Nachhaltigkeit ist jetzt sehr wichtig. Die Menschen wollen Produkte, die gut für sie und die Erde sind. Sie können diesem Bedarf gerecht werden, indem Sie Maschinen mit umweltfreundlichen Eigenschaften auswählen.

Neue Maschinen im Einsatz weniger Energie durch Wärmerückgewinnung und erneuerbare Energien.

Durch eine bessere Automatisierung wird nur das verwendet, was Sie benötigen, Also verschwenden Sie weniger.

Moderne Maschinen reinigen das Abwasser, bevor es Ihre Fabrik verlässt, So bleibt das Wasser sauber.

Energiesparende Designs helfen Ihnen, weniger Strom zu verbrauchen und Geld zu sparen.

Dank der intelligenten Steuerung können Sie Abfall erkennen und reduzieren, Machen Sie Ihr Unternehmen umweltfreundlicher.

🌱 Die Wahl einer umweltfreundlichen Maschine hilft dem Planeten und sorgt dafür, dass die Menschen Ihrer Marke vertrauen. Außerdem sparen Sie Geld, indem Sie weniger Energie verbrauchen und weniger Abfall produzieren.

Mit den modernen Seifenherstellungsmaschinen ist das möglich Ändern Sie die Einstellungen für verschiedene Seifen, Formen, und Größen. Sie können spezielle Seifen für Kunden herstellen und sich von der Masse abheben. Benutzerdefinierte Funktionen helfen Ihnen bei der Herstellung einzigartiger Seifen, wie lustige Formen oder besondere Gerüche. Mit diesen Optionen können Sie schneller arbeiten, bessere Seife herstellen, und mehr Geld verdienen.

Du kannst Formen wechseln, Verpackung, und neue Dinge hinzufügen wenn sich Trends ändern.

Dank der einfachen Steuerung können Sie schnell zwischen Produkten wechseln.

Sicherheitsfunktionen und Automatisierung sorgen für die Sicherheit Ihres Teams und eine reibungslose Arbeit.

Mit der richtigen Maschine können Sie Ihrer Kreativität freien Lauf lassen, hilft Ihrem Unternehmen beim Wachstum, und gibt Ihnen, was Sie brauchen, um an der Spitze zu bleiben.

Seifenherstellungsmaschine zu verkaufen: Budget und Wert

Kosten vs. Langfristige Investition

Wenn Sie nach einem suchen Seifenmaschine zu verkaufen, Vielleicht möchten Sie das günstigste auswählen. Das kann funktionieren, wenn Sie es nur für kurze Zeit benötigen. Wenn Sie möchten, dass Ihr Unternehmen wächst, Denken Sie über den langfristigen Wert nach. Eine hochwertige Maschine kostet zunächst mehr, aber es kann Ihnen später Geld sparen. Sie erhalten eine bessere Leistung, weniger Reparaturen, und jeden Tag wird mehr Seife hergestellt.

Sehen Sie, wie sich eine kluge Investition im Laufe der Zeit auszahlt:

Finanzkennzahl | Jahr 1 | Jahr 2 | Jahr 3 |

|---|---|---|---|

Verkäufe | $237,168 | $450,620 | $856,177 |

Reingewinn | $42,911 | $71,728 | $201,282 |

Bruttomarge % | 60.00% | 60.42% | 62.50% |

Barguthaben | $29,455 | $31,775 | $115,239 |

Inventar | $119,146 | $34,927 | $60,193 |

Betriebskosten | $81,000 | $169,800 | $245,100 |

Netto-Cashflow | -$47,245 | $2,320 | $83,463 |

Sie können sehen Umsatz und Gewinn steigen jedes Jahr. Der Kassenbestand wächst, und Sie haben mehr Geld zum Investieren. Eine zuverlässige Seifenherstellungsmaschine zum Verkauf hilft Ihnen, mit Bestellungen Schritt zu halten und die Kundennachfrage zu befriedigen. Wenn Sie für die Zukunft planen, Sie stellen Ihr Unternehmen auf Erfolgskurs.

💡 Tipp: Überlegen Sie, wie viel Sie an Reparaturen und verlorener Zeit sparen, wenn Sie sich jetzt für eine langlebige Maschine entscheiden.

Garantie und Support

Wenn Sie eine Seifenmaschine zum Verkauf kaufen, wollen Sie mehr als nur einen guten Preis. Großartiger Support und eine starke Garantie sind ebenso wichtig. Wenn etwas kaputt geht, Sie brauchen schnell Hilfe. Gute Lieferanten bieten Schulungen an, Ersatzteile, und schnelle Antworten auf Ihre Fragen.

Hier erfahren Sie, was andere Käufer über Top-Lieferanten sagen:

Der Lieferant hat eine durchschnittliche Bewertung von 4.81 von 5 Sterne von oben 158,000 Bewertungen.

Käufer schätzen den schnellen Versand und die große Produktauswahl.

Viele Menschen erwähnen die hohe Qualität und den zuverlässigen Kundenservice.

Kunden sagen, dass der After-Sales-Support schnell und hilfreich ist.

One-Stop-Shopping und faire Preise sorgen dafür, dass Käufer dem Lieferanten vertrauen.

Wenn du Wählen Sie eine Seifenherstellungsmaschine zum Verkauf, Überprüfen Sie die Garantie und den Support. Fragen Sie nach Schulungen, Ersatzteile, und wie schnell sie Probleme beheben. Ein guter Lieferant trägt dazu bei, dass Ihr Unternehmen reibungslos läuft.

Lieferant und Support

Die Auswahl des richtigen Lieferanten ist für Ihr Seifengeschäft sehr wichtig. Sie brauchen mehr als jemanden, der nur Maschinen verkauft. Die besten Lieferanten helfen Ihnen bei der Einrichtung Ihrer Maschine und schulen Ihr Team. Außerdem beheben sie Probleme schnell, wenn sie auftreten. Wenn Ihr Lieferant viel über Seifenherstellung weiß, Sie werden sich Ihrer Entscheidungen sicher sein.

Ruf und Erfahrung

Überprüfen Sie immer, wie lange ein Lieferant in diesem Bereich tätig ist. Lieferanten mit langjähriger Erfahrung können Probleme besser lösen. Sie verfügen in der Regel über gute Maschinen und hilfsbereite Support-Teams. Finden Sie Lieferanten mit guten Bewertungen und besonderen Zertifikaten. Diese Dinge zeigen, dass sie sich um ihre Kunden kümmern und Qualitätsprodukte herstellen.

Hier ist ein kurzer Blick auf einige Top-Anbieter und deren Angebot:

Name der Firma | Erfahrung & Ruf | Zertifizierungen | Support-Dienste | Wichtigste Highlights |

|---|---|---|---|---|

TY Cosmetic | 10+ Jahre, starkes R&D | 4 GMP-zertifizierte Standorte | Benutzerdefinierte Formel & Verpackung | Hochwertig, erschwinglich, Private-Label-Unterstützung |

BLK Corporation | 10+ Jahre, globale Exporte | GMP, ISO9001 | Eigenes Design, OEM/ODM | Breite Reichweite, exportiert nach 50+ Länder |

Hebei Baiyun Daily Chemical | Lange Geschichte, Qualität steht an erster Stelle | N / A | Technische Verbesserungen, neue Ausrüstung | Kundenorientiert, langanhaltende Seife |

Wenn ein Unternehmen schon lange besteht und zufriedene Kunden hat, Sie können ihnen vertrauen.

Tipp: Lesen Sie, was andere Kunden sagen und fragen Sie nach Referenzen. Ein guter Lieferant wird diese mit Ihnen teilen.

Wartung und Ersatzteile

Maschinen brauchen Pflege, damit sie jeden Tag gut funktionieren. Sie möchten einen Lieferanten, der Ihnen schnell Ersatzteile besorgen kann. Fragen Sie, ob sie Ihrem Team beibringen, wie man kleine Probleme löst. Dies hilft Ihnen, große Probleme zu stoppen, bevor sie entstehen.

Stellen Sie sicher, dass Sie es immer bekommen können Ersatzteile.

Prüfen Sie, ob der Lieferant regelmäßige Wartungspläne hat.

Fragen Sie, wie schnell Ihre Maschine repariert werden kann.

Ein guter Lieferant hält Ihr Geschäft am Laufen. Sie verbringen weniger Zeit mit dem Reparieren von Dingen und haben mehr Zeit mit der Herstellung von Seife.

Sie können das Richtige finden Seifenherstellungsmaschine indem Sie einige einfache Schritte befolgen. Erste, Entscheiden Sie, welche Art von Seife Sie herstellen möchten. Dann, Überlegen Sie, wie viel Seife Sie produzieren müssen. Danach, Achten Sie auf wichtige Funktionen und stellen Sie sicher, dass der Preis zu Ihrem Budget passt. Zuletzt, Wählen Sie einen Lieferanten, dem Sie vertrauen können. Wenn Sie sich für diese Schritte Zeit nehmen, wird Ihr Unternehmen größer. Schauen Sie sich diese Tabelle an, um zu sehen, wie jeder Schritt Ihrem Unternehmen hilft:

Schlüsselfaktor | Warum es wichtig ist | Vorteile für das Unternehmenswachstum |

|---|---|---|

Produktionskapazität | Passt zu dem, was Sie jetzt und später brauchen | Stoppt Verschwendung und hilft Ihnen, mehr zu verdienen |

Kompatibilität der Seifentypen | Stellt sicher, dass Ihre Seife zum Markt passt | Hilft Ihrem Unternehmen, sich abzuheben |

Rohstoffe & Formel | Funktioniert mit Ihren Seifenrezepten | Hält Ihre Seife gut und spart Material |

Automatisierungsstufe | Passt zu Ihrem Team und Ihren Geschäftsplänen | Spart Geld und ermöglicht die Herstellung von mehr Seife |

Wartung & Unterstützung | Sorgt dafür, dass Ihre Maschine einwandfrei funktioniert | Weniger Zeitaufwand für die Reparatur, mehr Zeit für die Seifenherstellung |

Wenn Sie diese Schritte befolgen, Sie werden sicher sein, die beste Seifenherstellungsmaschine für Ihr Unternehmen auszuwählen.

FAQ

Was ist die beste Seifenherstellungsmaschine für Anfänger??

Wenn Sie gerade erst anfangen, suche nach einem kleinen, halbautomatische Maschine. Diese Maschinen sind einfach zu bedienen und kosten nicht viel. Sie können die Grundlagen erlernen und später upgraden.

Wie oft muss ich meine Seifenherstellungsmaschine warten??

Sie sollten Ihre Maschine jede Woche überprüfen. Reinigen Sie es nach jedem Gebrauch. Ersetzen Sie verschlissene Teile, sobald Sie sie bemerken. Regelmäßige Pflege sorgt dafür, dass Ihre Maschine reibungslos läuft.

Kann ich eine Maschine sowohl für Stückseife als auch für Flüssigseife verwenden??

Die meisten Maschinen funktionieren am besten mit einer Seifensorte. Bei einigen fortgeschrittenen Modellen können Sie zwischen Balken und wechseln flüssige Seife, Möglicherweise benötigen Sie jedoch zusätzliche Teile. Fragen Sie vor dem Kauf Ihren Lieferanten.

Woher weiß ich, ob eine Maschine energieeffizient ist??

Suchen Sie nach Maschinen mit Energiesparfunktionen. Prüfen Sie, ob die Maschine weniger Strom verbraucht oder über umweltfreundliche Einstellungen verfügt. Sie können auch beim Lieferanten nachfragen Energiebewertungen oder Zertifizierungen.

Ich denke darüber nach, einige Wetten abzuschließen suncitybetvn. Scheint legitim. Jeder andere benutzt sie? Irgendwelche Empfehlungen, worauf man wetten sollte?

Hey, taya99casino, Du hast ein paar coole Promos am Laufen, es lohnt sich, hier zu bleiben. Guter Ort zum Nachschauen, Vielleicht findest du etwas Neues. Fühlen Sie sich glücklich? klicken Sie hier: taya99casino

Ich glaube nicht, dass der Titel Ihres Artikels mit dem Inhalt übereinstimmt, lol. Nur ein Scherz, Hauptsächlich, weil ich nach dem Lesen des Artikels einige Zweifel hatte.

Playbros is great if you like a clean interface. Easy on the eyes, and the mobile experience is smooth. Had a great time browsing the games offered by playbros.

Wplaymexico is legit! I dig their sportsbook – good odds and easy to understand. Plus, they have a decent casino section too. Probieren Sie es aus: wplaymexico.

Hey, 56788bet has a cool variety of events to bet on. I found some not-so-common games here! Check it now and see yourself! Überprüfen 56788Wette.