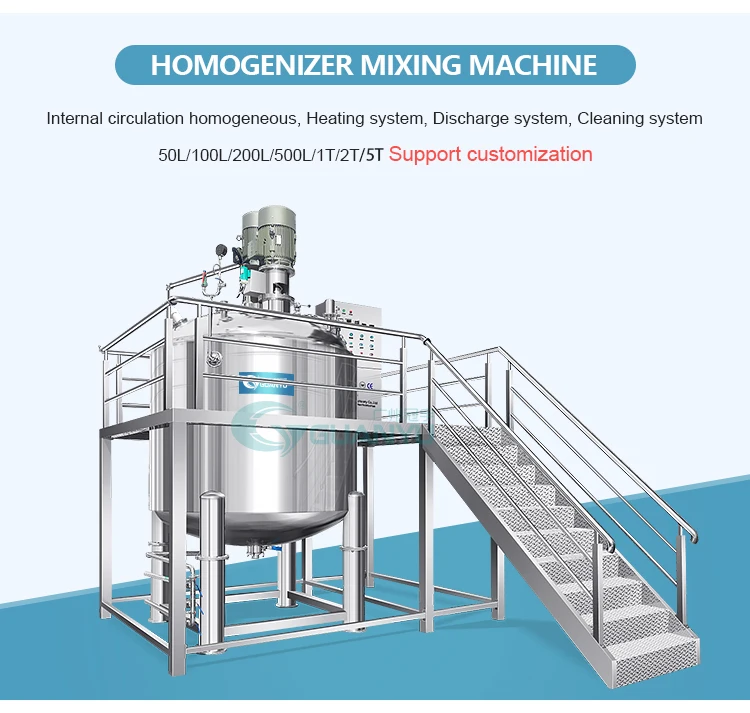

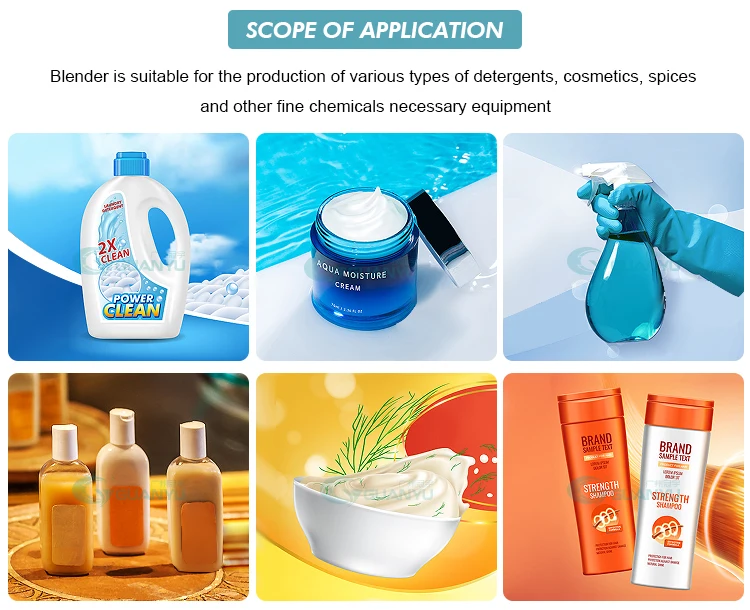

2000L Customized Liquid Detergent Mixing Equipment Vacuum Mixer Shampoo Conditioner Making Machine Liquid Soap Blending Tank

نموذج | مقدار(ل) | مزج قوة(كيلووات) | مزج تناوب سرعة(دورة في الدقيقة) | تجانس قوة(كيلووات) | Homogenizing rotation سرعة(دورة في الدقيقة) | طريقة التدفئة |

جيم-200 | 200 | 1.5 | 0~63 | 4.0 | 0~ 3200 | تسخين البخار أو التدفئة الكهربائية |

جيم-500 | 500 | 3.0 | 0~63 | 7.5 | 0~ 3200 | |

جيم-1000 | 1000 | 4.0 | 0~63 | 11 | 0~ 3200 | |

جيم-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~ 3200 | |

جيم-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~ 3200 | |

جيم-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~ 3200 | |

جيم-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~ 3200 |

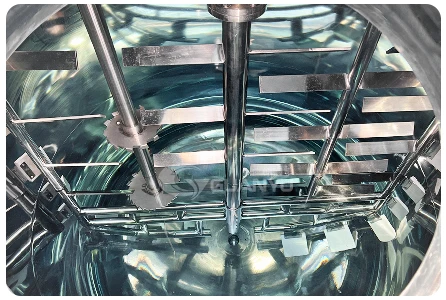

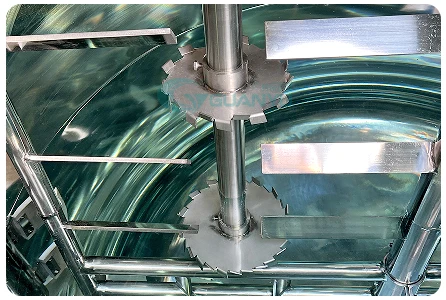

مجداف الخلط

مشتت

يمكن أن تنقطع التسننات العلوية والسفلية لقرص التشتت, تأثير, تحطيم وتفريق المواد مثل الطلاء, مسحوق جاف وصلب سائل بسرعة عالية, وذلك لتحقيق الخلط السريع, تحلل, التشتت والصقل

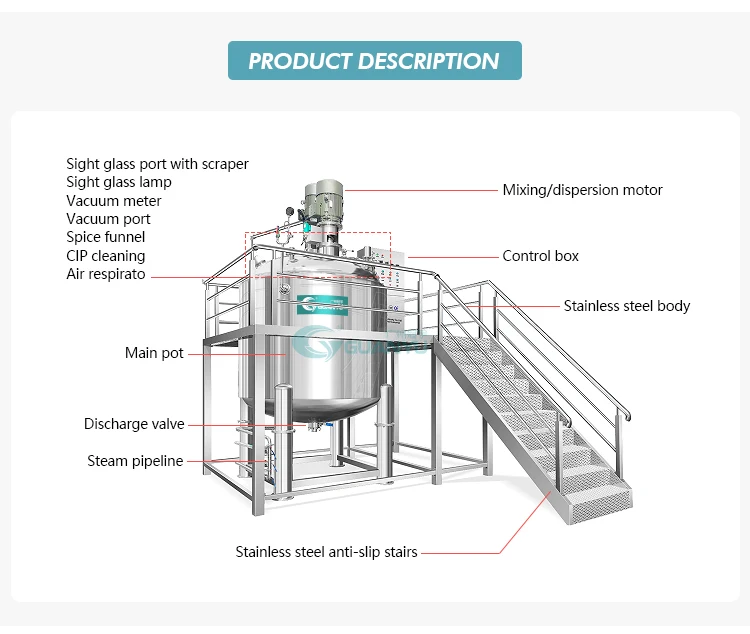

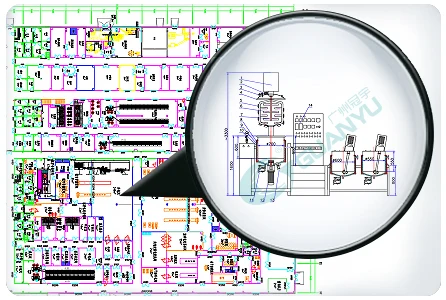

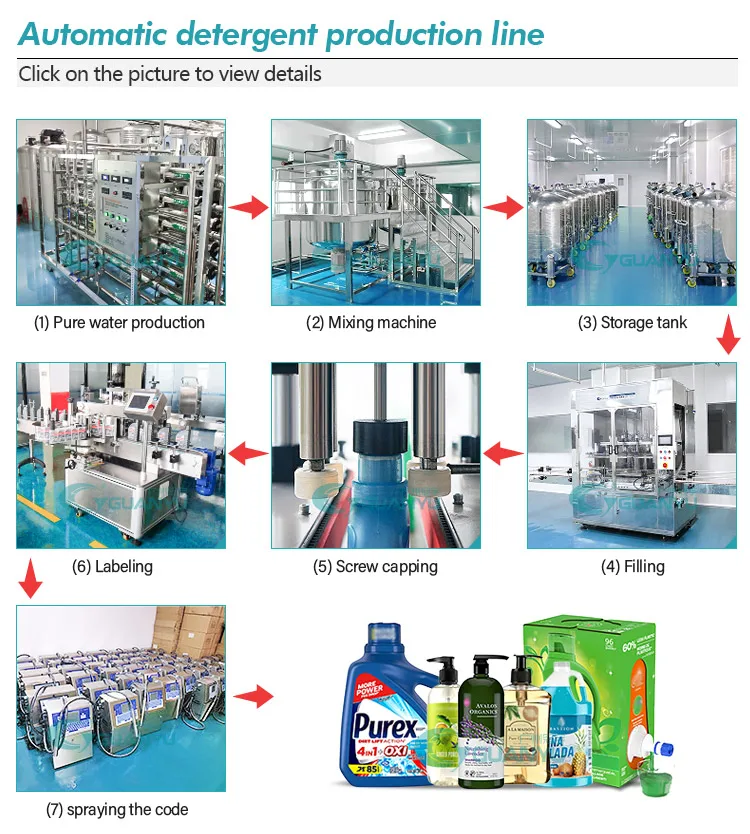

machine آلة خزان الخلاط للمستحلب تتكون من الخزان الرئيسي للمستحلب الفراغ, علبة الزيت ,وعاء الماء, نظام الرفع الهيدروليكي (مع أو بدون),التدفئة &نظام التبريد,نظام التفريغ,نظام التحكم التلقائي أو نظام التحكم في الزر اليدوي,إلخ.

◭ يعتمد خلط المحرض من نوع الكاشطة محول التردد لضبط السرعة , بحيث يتم إنتاج منتجات عالية الجودة بعمليات مختلفة وفقًا لمتطلبات العملاء.

◭ يمكن لمختلط متجانسة عالي السرعة المتنوعة مزج المواد الخام والسائلة الصلبة بقوة ويمكن أن يذوب بسرعة

العديد من المواد غير القابلة للذوبان مثل AES , إيسا , LSA , إلخ. خلال عملية إنتاج المنظفات السائلة وذلك لتوفير استهلاك الطاقة وتقصير فترة الإنتاج. يتبنى متجانسة القص العالي التكنولوجيا الألمانية, 0~ 3500 دورة في الدقيقة متغيرة السرعة, ويمكن أن تصل السرعة القصوى إلى 4500 دورة في الدقيقة,درجة القص حوالي 0.2 ~ 5um.

◭ جسم الخزان ملحور بواسطة صفيحة من الفولاذ المقاوم للصدأ من ثلاث طبقات مستوردة. يعتمد جسم الخزان والأنابيب على تلميع المرآة أو اللمسة النهائية غير اللامعة , الذي يتوافق تمامًا مع متطلبات GMP.

◭cactording لمتطلبات العميل , يمكن للخزان تسخين وتبريد المواد. طريقة التدفئة بما في ذلك التدفئة بالبخار والتدفئة الكهربائية. سهل التفريغ , التفريغ المباشر السفلي أو عن طريق مضخة النقل.

◭الخزان الرئيسي للاستحلاب ,إنه تصميم فراغ ,الحد الأقصى لدرجة الفراغ -0.09الآلام والكروب الذهنية.

◭ يمكننا اختيار الرفع الهيدروليكي ,من السهل التنظيف. أو إذا كان المصنع لديه مساحة محدودة,يمكننا تقديم المشورة للنوع الثابت, الجزء العلوي

cover can not lifted,ولكن هناك فتحة ضغط,يمكننا فتحه للتحقق من الخزان في الداخل .

◭ الوعاء والوعاء المائي بمثابة تسخين مسبقًا وتختلطًا مسبقًا,من الضروري إنتاج الدُفعات,it efficiently save the preparation

وقت.

◭ يمكننا اختيار نظام التحكم الآلي PLC ,أو صندوق التحكم اليدوي بالزر,ذلك يعتمد على الطلب الخاص بك.

تصميم الختم

جهاز تنفس, باستخدام سيمنز, ABB والمحركات الأخرى

التدفئة

حالة التحريك والاستحلاب.

وحدة التحكم

توقيت العمل, استخراج الفراغ, التدفئة البينية, إلخ.

(التحكم PLC اختياري)

خدمة

من أجل تزويدك بآلة أكثر ملاءمة, يرجى الاتصال بنا لمناقشة التفاصيل

2.ما هو انتاجك اليومي?

3.هل التدفئة مطلوبة?

4.هل من الضروري الفراغ?

5.ما إذا كانت هناك حاجة إلى تنظيم سرعة تحويل التردد?

6.ما هو الجهد المحلي الخاص بك?

Rex –

I’m no longer positive the place you’re getting

your information, however great topic. I needs to spend a while learning

much more or working out more. Thanks for great information I

used to be searching for this information for my mission.

قم أيضًا بزيارة صفحتي الرئيسية; كوبونات NORDVPN الملهم

Edwina –

Heya i’m for the first time here. I found this board and I in finding

انها مفيدة حقا & لقد ساعدني ذلك كثيرًا. I hope to provide

something back and help others such as you aided me.

موقع الويب الخاص بي … كوبونات NORDVPN الملهم – http://Tinyurl.com –

Tonja –

350فيرفاكس Nordvpn الترويج

Hi there to all, the contents present at this web page are genuinely remarkable

for people knowledge, حسنًا, استمروا في العمل الجيد يا رفاق.

Makayla –

رمز الترويجي Nordvpn 350فيرفاكس

I think this is among the most important info for me. And i’m

glad reading your article. But should remark on few general things, أسلوب الموقع رائع, the articles is

really nice : د. أحسنت, هتافات

Claudia –

مرحبًا يا من هناك! أردت فقط أن أسأل عما إذا كان لديك أي مشاكل مع المتسللين?

مدونتي الأخيرة (وورد) was hacked and I ended up losing a few months of hard work due to no back up.

Do you have any methods to prevent hackers?

قم أيضًا بزيارة صفحتي … رمز قسيمة eharmony 2025

Phyllis –

When someone writes an article he/she maintains the idea of a user in his/her brain that how a user can understand

هو - هي. Thus that’s why this article is great. شكرًا!

منشور مدونتي … VPN

Emma –

I am regular visitor, كيف حالكم جميعا? This article posted at this web site is really nice.

موقعي … VPN

Coleman –

It’s an remarkable post ما هو رمز VPN all the online people; they will obtain advantage

from it I am sure.

Verla –

It is appropriate time to make some plans for the long run and it is time to be happy.

I’ve learn this publish and if I may I want to suggest you few fascinating issues

or advice. Perhaps you can write subsequent articles regarding this article.

I wish to read more issues about it!

مدونتي … VPN

Howard –

هيا أنا لأول مرة هنا. جئت عبر هذا اللوحة وأجد أنه مفيد حقًا & هو - هي

helped me out much. I hope to give something back and help others like you aided me.

قم أيضًا بزيارة منشور مدونتي VPN

ارشي –

هل فكرت يومًا في تضمين ما هو أكثر قليلاً من مجرد مقالاتك؟?

أعني, what you say is important and everything.

Nevertheless think of if you added some great graphics or videos to give your posts more,

“البوب”! Your content is excellent but with pics and videos, this website could definitely be one

of the best in its niche. Good blog!

موقع الويب الخاص بي: http://winkler-martin.de/messages/61849.html

Beth –

مرحبًا! I could have sworn I’ve been to this website before but after browsing through some of

the articles I realized it’s new to me. Regardless, I’m definitely happy I stumbled upon it and I’ll be bookmarking it and checking back often!

صفحة الويب الخاصة بي – https://tinyurl.com/ms8n5mcm