200l Body Face Facial Cream Making Machine Vacuum Homogenizing Conditioner Vacuum Mixer Homogenizer Mixing Machine

وصف المنتجات

يقدم:

بناء:يتم تطبيق خزانات خلط الفولاذ المقاوم للصدأ على نطاق واسع في المشروبات, طعام, ألبان, الصناعات الكيميائية والعمليات usedas الخلاط الخلاط, خزان المخزن المؤقت وخزان التخزين, التي يمكن التنظيف للمعايير الصحية .1.Cappacity :100-20000L 2.Single طبقة/ طبقات مزدوجة/ ثلاث طبقات:0.75-5.5KW4.Materials هي جميعها من الفولاذ المقاوم للصدأ. :1.فتحة مانول مفتوحة سريعة. (وفقا لمتطلبات العملاء ).7.سُلُّم (وفقا لمتطلبات العملاء).8.PADDLE Blender .9 (وفقا لمتطلبات العملاء) .10.إيدان مقاوم .

نموذج | مقدار(ل) | مزج القوة(كيلووات) | مزج سرعة الدوران(دورة في الدقيقة) | قوة متجانسة(كيلووات) | تجانس سرعة الدوران(دورة في الدقيقة) | طريقة التدفئة |

جيم-200 | 200 | 1.5 | 0~63 | 4.0 | 0~ 3200 | تسخين البخار أو التدفئة الكهربائية |

جيم-500 | 500 | 3.0 | 0~63 | 7.5 | 0~ 3200 | |

جيم-1000 | 1000 | 4.0 | 0~63 | 11 | 0~ 3200 | |

جيم-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~ 3200 | |

جيم-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~ 3200 | |

جيم-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~ 3200 | |

جيم-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~ 3200 |

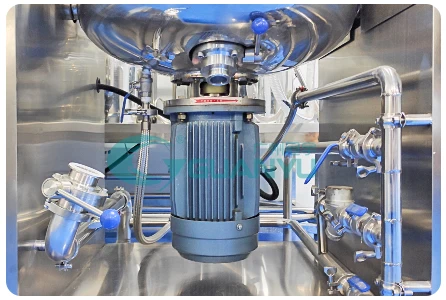

مجداف الخلط

تنظيم سرعة تحويل التردد 0-62r/min, سيتم تصميم شكل الشفرات وفقًا للمواد الخاصة بك.

الخالط

تنظيم سرعة تحويل التردد 0-3000r/min, رأس قص متجانس مواد قص عالية السرعة, بحيث تتكسر المواد وتختلط تماماً!

وعاء الزيت والماء

مرحلة المياه قبل المعالجة و

وعاء مرحلة الزيت لتسخين وتفرق

المواد الخام, ثم نقلها إلى

وعاء رئيسي لبدء الإنتاج.

وعاء مرحلة الزيت لتسخين وتفرق

المواد الخام, ثم نقلها إلى

وعاء رئيسي لبدء الإنتاج.

وحدة التحكم

تعرض لوحة التحكم وتتحكم في درجة حرارة الجهاز, خلط, التجانس, بيانات الضغط, إلخ. في الواقع

وقت.

( التحكم الاختياري PLC )

وقت.

( التحكم الاختياري PLC )

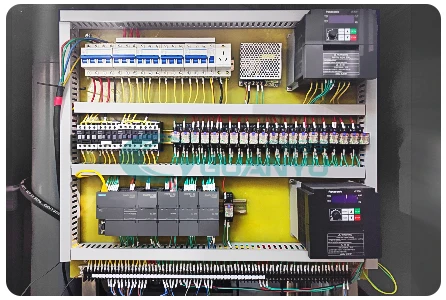

صندوق كهربائي

استخدم مكونات ذات علامات تجارية مشهورة عالميًا لضمان جودة المعدات وعمر الخدمة الأطول

خدمة

سنقوم بتصميم الرسومات وفقًا لمتطلباتك ونقدم حلولًا واحدة.

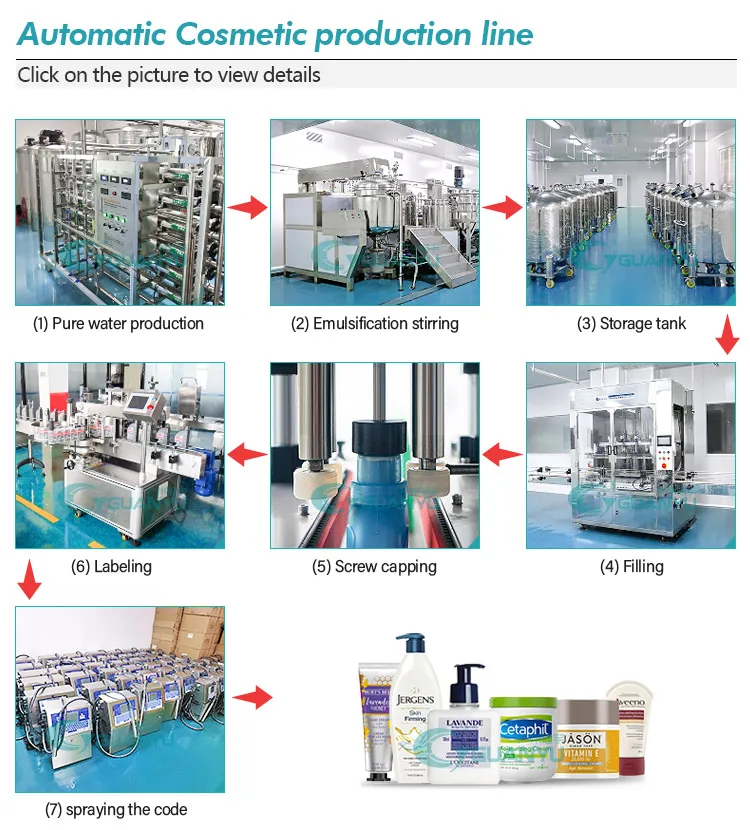

تكوين المنتج

معلومات عنا

عملية القضية الناجحة

الشهادات

التعليمات

التعليقات

لا توجد توصيات بعد.