200L 500L Mayonnaise Emulsifier Mixing Machine Cream Cheese Homogenizing Making Machine Mixer

تكوين المنتج

وصف المنتجات

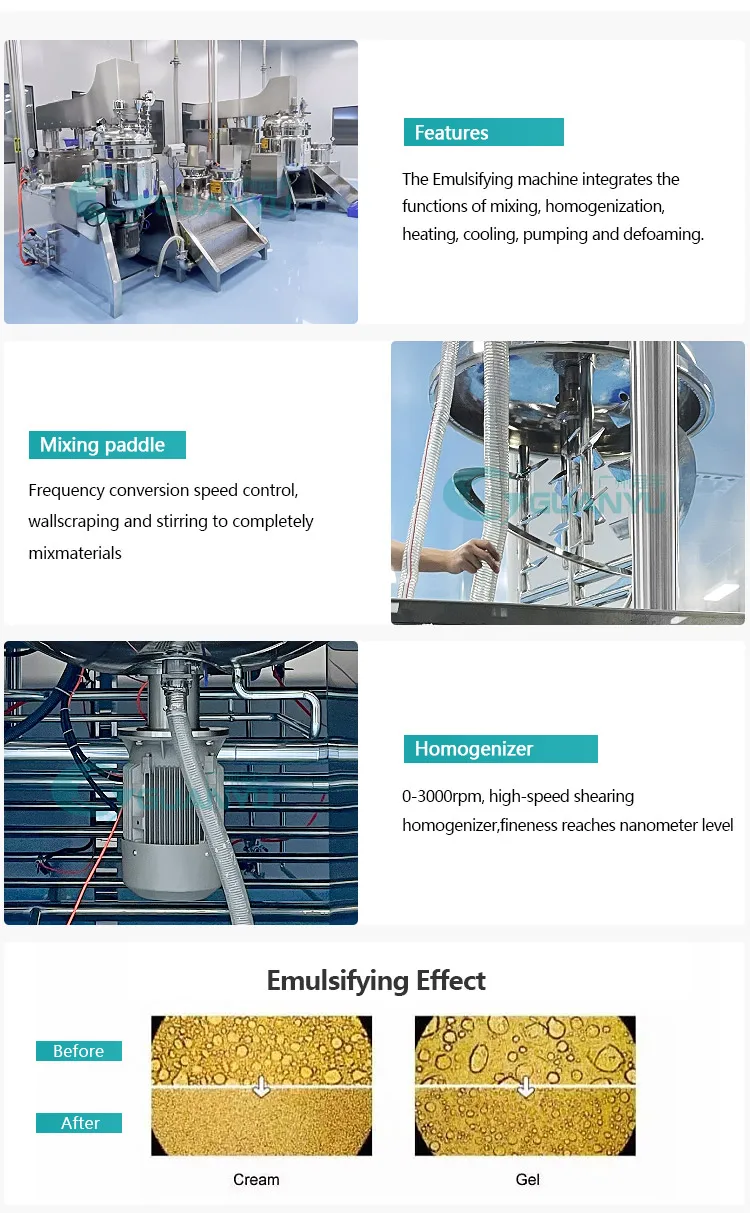

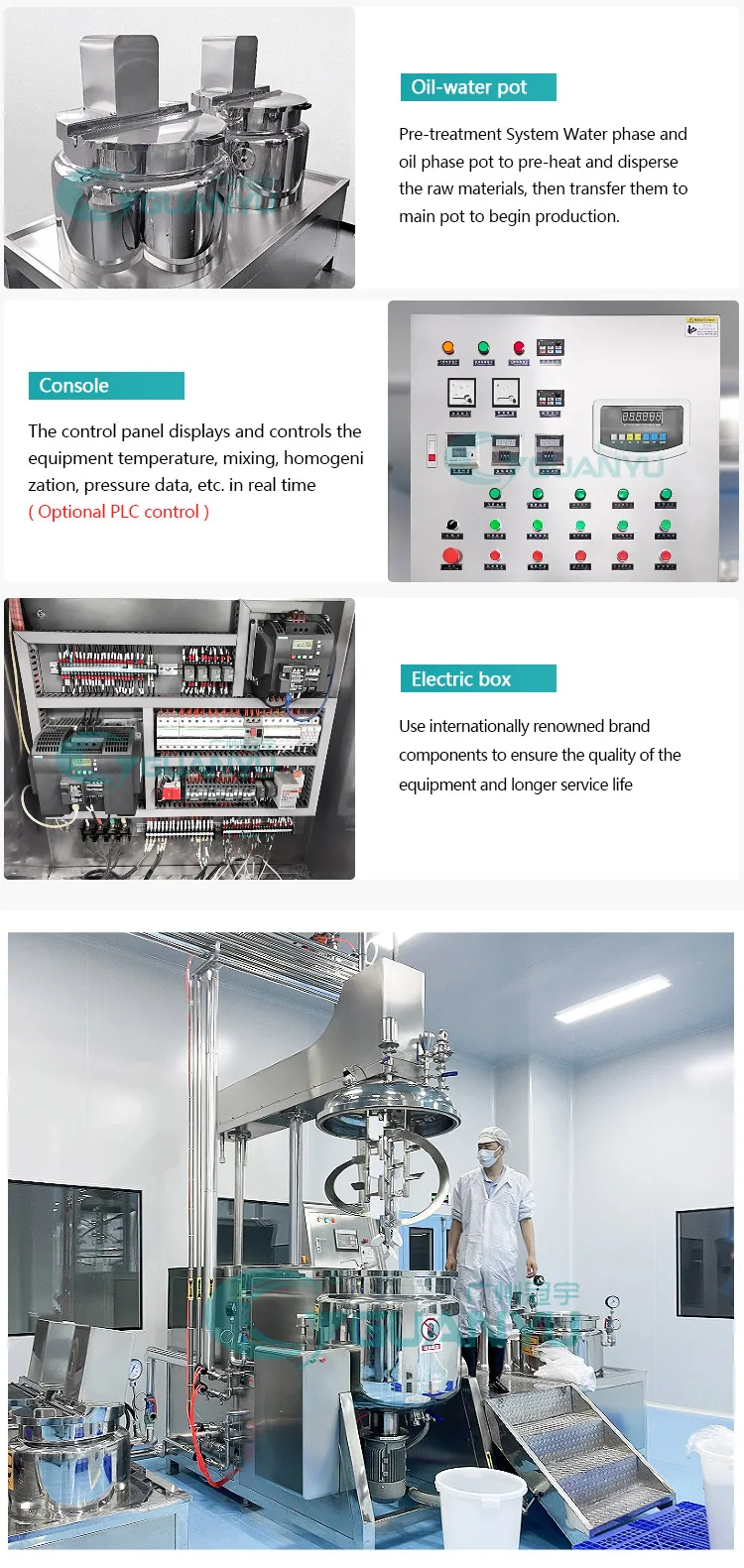

◭Vacuum emulsifying mixer tank machine is consist of vacuum emulsifying main tank, oil pot ,water pot, hydraulic lifting system (with or without),heating &cooling system,vacuuming system,PLc automatic control or manual button control system,إلخ. cheese making machine cheese making machine◭The scraper type agitator mixing adopts the frequency converter for speed adjustment , بحيث يتم إنتاج منتجات عالية الجودة بعمليات مختلفة وفقًا لمتطلبات العملاء.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolvemany indissoluble materials such as AES , إيسا , LSA , إلخ. during the liquid detergent production process so as to save energy consumption and shorten production period. High Shear Homogenizer adopts German Technology, 0~ 3500 دورة في الدقيقة متغيرة السرعة, and maximum speed can reach to 4500 دورة في الدقيقة,درجة القص حوالي 0.2 ~ 5um. ◭ جسم الخزان ملحوم بلوحة فولاذية مقاومة للصدأ مستوردة ثلاثية الطبقات. يعتمد جسم الخزان والأنابيب على تلميع المرآة أو اللمسة النهائية غير اللامعة , which fully conforms to GMP requirements. cheese making machine◭According to customer requirement , يمكن للخزان تسخين وتبريد المواد. طريقة التدفئة بما في ذلك التدفئة بالبخار والتدفئة الكهربائية. سهل التفريغ , bottom direct discharge or by transfer pump.◭The emulsifying main tank ,it is vacuum design ,the maximum vacuum degree is -0.09الآلام والكروب الذهنية. cheese making machine◭We can choose hydraulic lifting ,it is easy for cleaning. or if factory has limited space,we can advise to fixed type, the topcover can not lifted,but there is pressure manhole,we can open it to check the tank inside . cheese making machine◭Oil pot and water pot as pre-heating and pre-mixing,it is necessary for batch production,it efficiently save the preparationtime. cheese making machine◭We can choose PLC automatic control system ,أو صندوق التحكم اليدوي بالزر,ذلك يعتمد على الطلب الخاص بك.

نموذج | حجم العمل(ل) | Mixing power(كيلووات) | Mixing speed(دورة في الدقيقة) | Homogenizing power(كيلووات) | Homogenizing speed(دورة في الدقيقة) | طريقة التدفئة |

GYE-5 | 5 | 0.37 | 0~63 | 0.75 | 0~ 3500 | كهربائي |

جي-50 | 50 | 1.1 | 0~63 | 2.2 | 0~ 3500 | كهربائي |

جي-100 | 100 | 2.2 | 0~63 | 3~4 | 0~ 3500 | كهربائي |

جي إي-200 | 200 | 2.2 | 0~63 | 4~5.5 | 0~ 3500 | Steam heating Or Electric heating |

جي-500 | 500 | 3.0 | 0~63 | 7.5 | 0~ 3500 | |

جي-1 | 1000 | 4.0 | 0~63 | 11 | 0~ 3500 | |

GYE-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~ 3500 | |

GYE-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~ 3500 | |

GYE-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~ 3500 | |

GYE-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~ 3500 |

تكوين المنتج

معلومات عنا

عملية القضية الناجحة

الشهادات

التعليمات

Angelo –

Hi! Do you know if they make any plugins to assist with SEO?

I’m trying to get my blog to rank for some targeted keywords but I’m not seeing very good gains.

If you know of any please share. Thanks! You

can read similar art here: Warm blankets