نموذج | مقدار(ل) | تمزج الطاقة (kw) | مزج سرعة الدوران (r/m) | قوة متجانسة(كيلووات) | سرعة التجانس(دورة في الدقيقة) | طريقة التدفئة |

GY-200 | 200 | 1.5 | 0~63 | 4.0 | 0~ 3200 | تسخين البخار أو تسخين Electirc |

GY-500 | 500 | 3.0 | 0~63 | 7.5 | 0~ 3200 | |

GY-1000 | 1000 | 4.0 | 0~63 | 11 | 0~ 3200 | |

GY-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~ 3200 | |

GY-2000 | 2000 | 7.5 | 0~63 | 15-15.8 | 0~ 3200 | |

GY-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~ 3200 | |

GY-5000 | 5000 | 11 | 0~63 | 18.5-22 | 0~ 3200 |

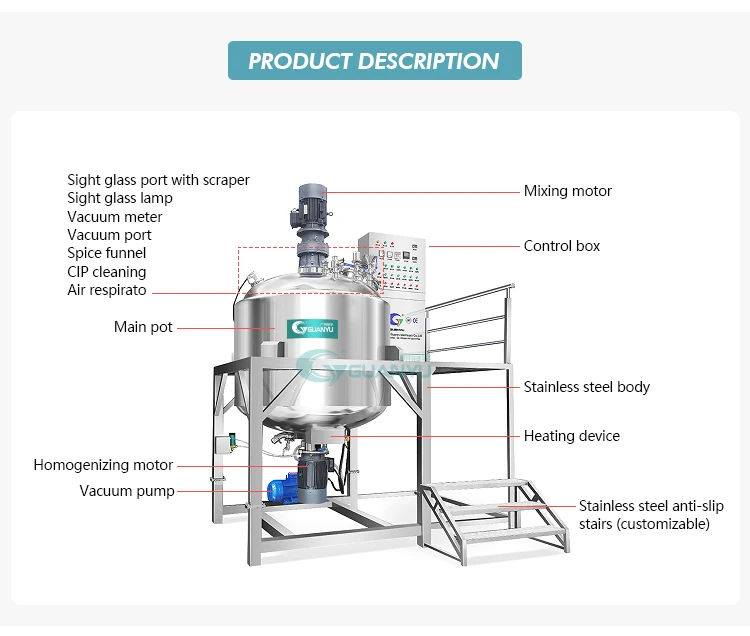

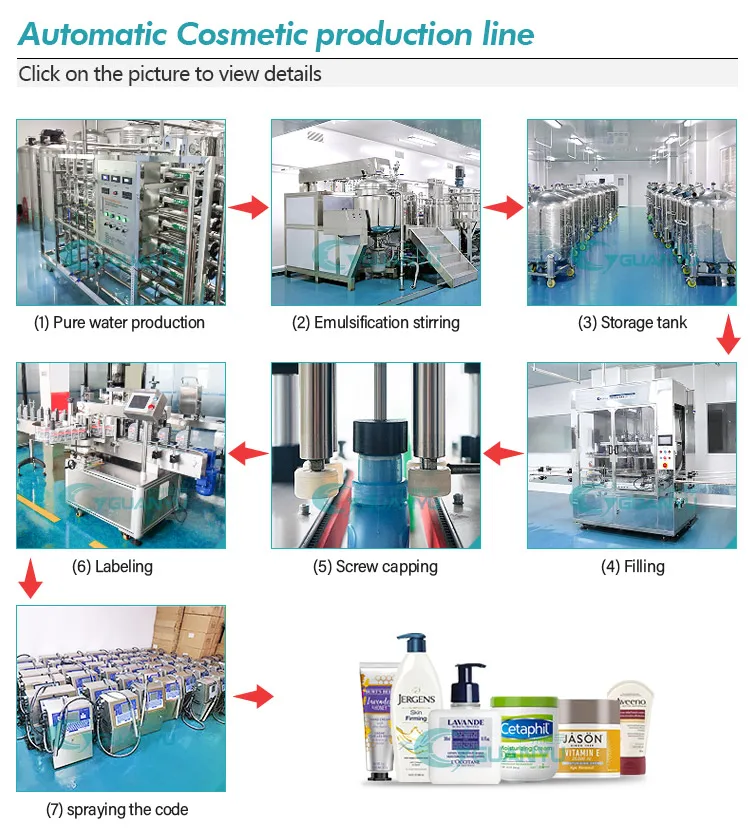

العروض والميزات

◭ يعتمد خلط تجريف الجدار الشامل على محول التردد لتعديل السرعة , بحيث عالية

جودة المنتجات من عمليات مختلفة وفقًا لمتطلبات العملاء.

◭ يمكن للمتجانس المتنوع عالي السرعة أن يمزج بقوة المواد الخام الصلبة والسائلة ويمكن أن يذوب بسرعة quonyindis

مواد قابلة للذوبان مثل AES , إيسا , LSA , إلخ. أثناء عملية إنتاج المنظفات السائلة وذلك لتوفير استعادة الطاقة

وتقصير فترة الإنتاج.

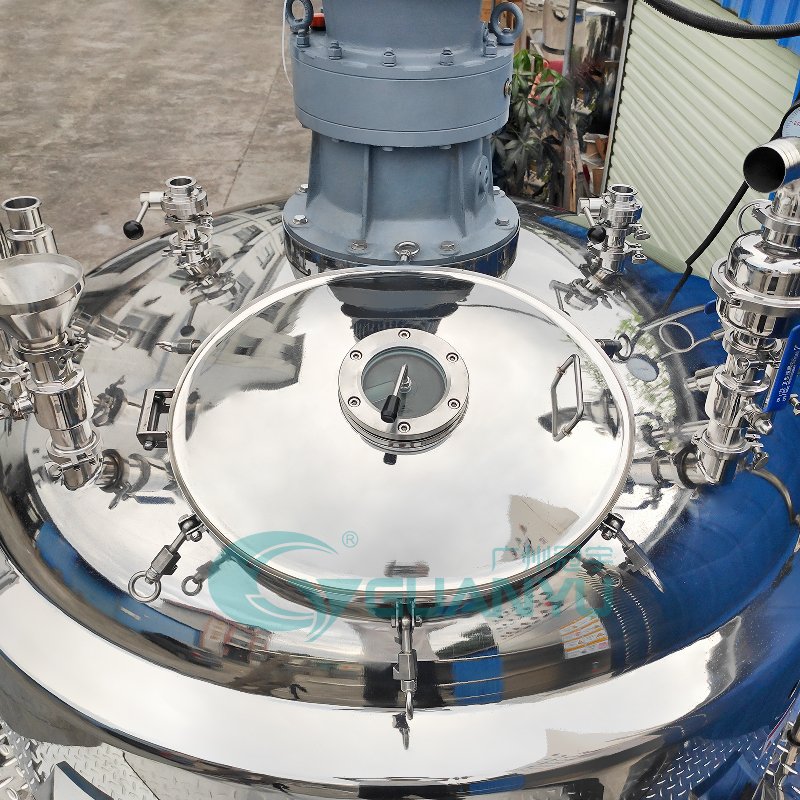

◭ جسم الوعاء ملحوم بلوحة فولاذية مقاوم للصدأ ثلاث طبقات مستوردة. يعتمد جسم الخزان والأنابيب تلميع القفاز , أيّ

يتوافق تمامًا مع متطلبات GMP.

◭cactording لمتطلبات العميل , يمكن للخزان تسخين وتبريد المواد. طريقة التدفئة بما في ذلك تسخين البخار والكهرباء

التدفئة. سهل التفريغ , التفريغ المباشر السفلي أو عن طريق مضخة النقل.

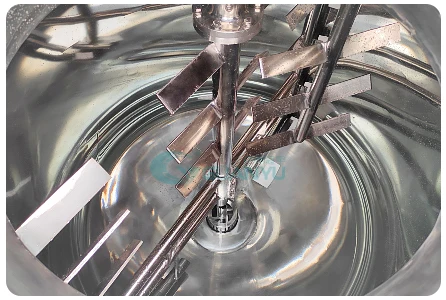

مجداف الخلط

الخالط

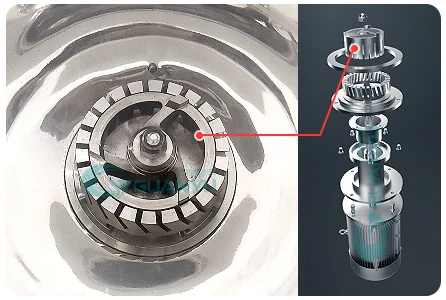

تنظيم سرعة تحويل التردد 0-3200r/min, رأس قص متجانس مواد قص عالية السرعة, بحيث تتكسر المواد وتختلط تماماً!

مضخات فراغ

تسريح

(إذا لزم الأمر, يمكن تجهيز مضخة التفريغ لاستخراج المواد مباشرة)

وحدة التحكم

توقيت العمل, استخراج الفراغ, التدفئة البينية, إلخ.

(التحكم PLC اختياري)

خدمة

استخدم مكونات ذات علامات تجارية مشهورة عالميًا لضمان جودة المعدات وعمر الخدمة الأطول

التعليقات

لا توجد توصيات بعد.