يستمر الطلب على الصابون السائل في النمو, مدفوعة بزيادة الوعي بالنظافة والحاجة إلى حلول تنظيف فعالة. أساسي لعملية الإنتاج هذه آلة صنع الصابون السائل, التي تأتي في تكوينات مختلفة, بما في ذلك الخيارات مع أو بدون متجانسة, قدرات التدفئة, وتصميمات واحدة أو ثلاث طبقات. هذه المقالة تتدفق إلى الميزات, فوائد, وتطبيقات هذه الآلات, توفير نظرة عامة شاملة للمشترين والمصنعين المحتملين.

أنواع آلات صنع الصابون السائل

- نظرة عامة أساسية

تم تصميم آلات صنع الصابون السائل لأتمتة عملية خلط المواد الخام, مثل الزيوت, الصودا الكاوية, والماء, في منتج صابون سائل متجانس. يعتمد اختيار الآلة إلى حد كبير على القدرة الإنتاجية, تناسق المنتج المطلوب, والميزانية المتاحة. - المتجانس مقابل. غير التربط

- مع متجانسة: الآلات المزودة بموظف متجانس تضمن مزيجًا موحدًا من المكونات, وهو أمر بالغ الأهمية لتحقيق جودة المنتج المتسقة. هذا مهم بشكل خاص للمصنعين الذين يتطلعون إلى إنتاج صابون سائل راقي مع قوام ومظاهر محددة.

- بدون متجانسة: الآلات غير المتجانسة أبسط وقد تكون أكثر فعالية من حيث التكلفة. فهي مناسبة للعمليات الأصغر أو لإنتاج تركيبات صابون سائلة أساسية.

- خيارات التدفئة

- آلات ساخنة: تسمح الآلات ذات إمكانات التدفئة المدمجة بذوبان الدهون الصلبة وتسريع تفاعلات saponification, مما يؤدي إلى أوقات إنتاج أسرع. هذه الميزة ضرورية للمصنعين الذين يتطلعون إلى تحسين الكفاءة وتلبية الطلب الأعلى.

- آلات غير مسخنة: تعتمد هذه الآلات على درجات الحرارة المحيطة, جعلها مناسبة لصانعي الصابون البارد أو أولئك الذين ينتجون صابون سائل لا يحتاجون إلى التدفئة.

- طبقة واحدة مقابل. آلات ثلاث طبقات

- طبقة واحدة: هذه الآلات عادة ما تكون أقل تكلفة وأسهل في العمل. إنها مثالية لركضات الإنتاج الأصغر والشركات التي تبدأ للتو في صناعة الصابون السائل.

- ثلاث طبقة: توفر آلات ثلاث طبقات عزلًا معززًا والتحكم في درجة الحرارة, وهو مفيد للعمليات التي تتطلب إدارة حرارية دقيقة. يفضل هذا التصميم من قبل الشركات المصنعة الكبيرة التي تهدف إلى إنتاج عالي الجودة على نطاق واسع.

الميزات الرئيسية لآلات صنع الصابون السائل

- الأتمتة والتحكم

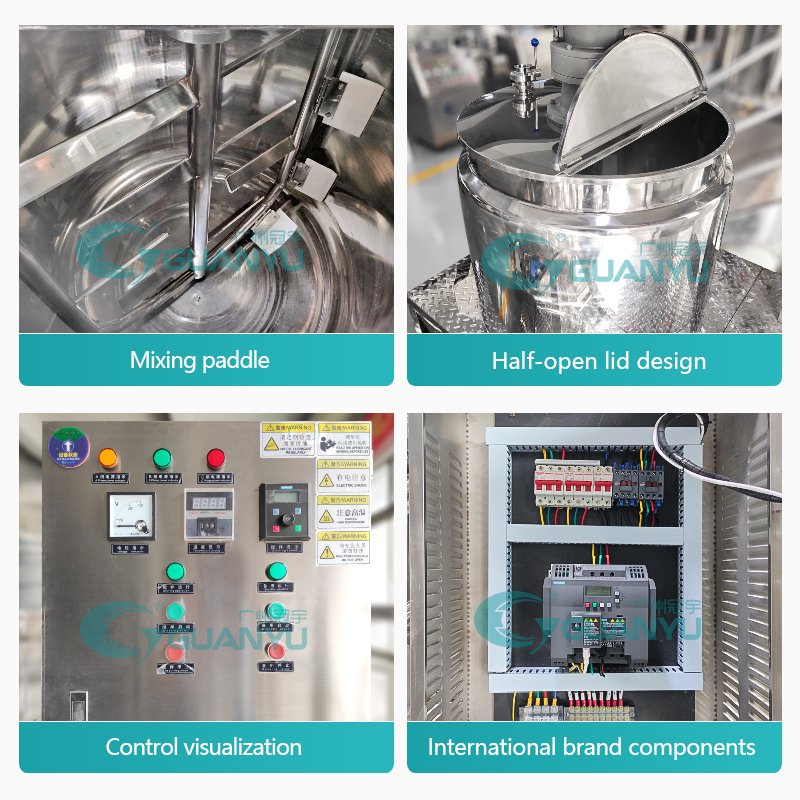

تأتي معظم آلات صنع الصابون السائل الحديثة مجهزة بأنظمة تحكم متقدمة تسمح بإجراء تعديلات دقيقة على سرعات الخلط, درجات الحرارة, ونسب المكونات. هذه الأتمتة تقلل من تكاليف العمالة وتقليل الخطأ البشري. - جودة المواد

مواد بناء الماكينة - الفولاذ المقاوم للصدأ - تتانة, سهولة التنظيف, ومقاومة التآكل. هذا مهم بشكل خاص في صناعة صنع الصابون, حيث النظافة ذات أهمية قصوى. - القدرة الإنتاجية

اعتمادا على التصميم, يمكن لآلات صنع الصابون السائل التعامل مع أحجام دفعة مختلفة. قد تنتج الآلات الأصغر مئات لتر لكل دفعة, في حين أن النماذج الأكبر يمكنها التعامل مع آلاف لتر, تقديم الطعام لمقاييس الأعمال المختلفة. - ميزات السلامة

السلامة هي اعتبار حاسم في أي بيئة تصنيع. تم تصميم آلات صنع الصابون السائل مع آليات السلامة, بما في ذلك ضوابط الإغلاق في حالات الطوارئ, صمامات تخفيف الضغط, وحراس الحماية المشغل.

مزايا استخدام آلات صنع الصابون السائل

- الكفاءة والسرعة

تقنيات الأتمتة والخلط المتقدم في آلات صنع الصابون السائل تقلل بشكل كبير من أوقات الإنتاج مقارنة بالطرق اليدوية. تتيح هذه الكفاءة للمصنعين توسيع نطاق العمليات والاستجابة بسرعة لمتطلبات السوق. - الاتساق في الجودة

يضمن التحكم الدقيق في نسب المكونات وعمليات الخلط أن كل مجموعة من الصابون السائل تلبي نفس معايير الجودة. هذا الاتساق أمر بالغ الأهمية لبناء سمعة العلامة التجارية وثقة العملاء. - فعالية التكلفة

في حين أن الاستثمار الأولي في آلة صنع الصابون السائل قد يكون كبيرًا, المدخرات طويلة الأجل في المخاض, نفايات المواد, ويمكن أن يعوض وقت الإنتاج هذه التكاليف. يمكن للشركات تحقيق هوامش ربح أعلى من خلال العمليات المبسطة. - التخصيص

توفر العديد من آلات صنع الصابون السائل القدرة على إنتاج مجموعة واسعة من المستحضرات, السماح للمصنعين بتلبية احتياجات قطاعات السوق المختلفة, مثل الصابون العضوي أو التخصص. يمكن أن تساعد هذه المرونة الشركات على التمييز بينها في سوق تنافسي.

تطبيقات آلات صنع الصابون السائل

- صناعة التجميل

الصابون السائل هو العنصر الرئيسي في صناعة مستحضرات التجميل, تستخدم في منتجات مثل صابون اليد, غسل الجسم, والشامبو. يستفيد الشركات المصنعة في هذا القطاع من الآلات عالية الجودة التي تضمن تناسق المنتج والجاذبية. - منتجات التنظيف المنزلية

ارتفع الطلب على حلول التنظيف المنزلي, تلعب آلات صنع الصابون السائل دورًا حاسمًا في إنتاج عوامل تنظيف فعالة تلبي احتياجات المستهلكين. - التطبيقات الصناعية

بعض الشركات المصنعة تنتج الصابون السائل بالجملة للتطبيقات الصناعية, بما في ذلك المطهرات ومرضى. الآلات المصممة للإنتاج ذو الحجم الكبير ضرورية لتلبية هذه المطالب بكفاءة.

خاتمة

ال آلة صنع الصابون السائل هو أحد الأصول الحيوية للمصنعين الذين يتطلعون إلى إنتاج صابون سائل عالي الجودة. مع خيارات تتراوح بين المتجانسين وقدرات التدفئة إلى تصميمات واحدة أو ثلاث طبقات, هذه الآلات تلبي احتياجات الإنتاج المختلفة. من خلال الاستثمار في آلة مناسبة, يمكن للشركات تعزيز الكفاءة, ضمان جودة المنتج, وفي النهاية تزدهر في سوق الصابون التنافسي.

إذا كنت تفكر في دخول أعمال إنتاج الصابون السائل أو تتطلع إلى ترقية المعدات الحالية الخاصة بك, إن فهم القدرات وتكوينات آلات صنع الصابون السائل سيوجهك نحو اتخاذ قرار مستنير.

Luckywinplus يبدو واعدا! أنا دائمًا أبحث عن موقع يكون فيه الحظ إلى جانبي. أي شخص يعرف أي شيء عن برنامج الولاء الخاص بهم? com.uckywinplus

يو, Evotaya777 هو المكان المناسب للاستمتاع ببعض المرح الجاد. لقد كنت ألعب هنا لفترة من الوقت وأقضي وقتًا ممتعًا دائمًا. الدفع evotaya777, قد تصبح مدمن مخدرات!