Model | Volume(L) | Blending power(kw) | Blending rotation speed(r/m) | homogenizing power(kw) | homogeniziing speed(r/min) | heating method |

GY-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | steam heating or electirc heating |

GY-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GY-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GY-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GY-2000 | 2000 | 7.5 | 0~63 | 15-15.8 | 0~3200 | |

GY-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GY-5000 | 5000 | 11 | 0~63 | 18.5-22 | 0~3200 |

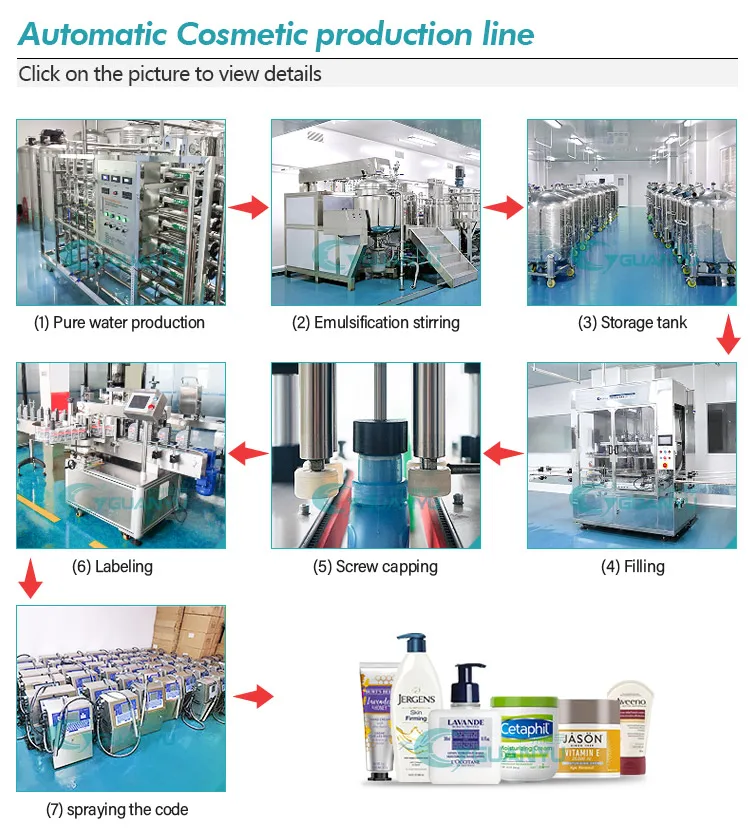

PERFORMANCES AND FEATURES

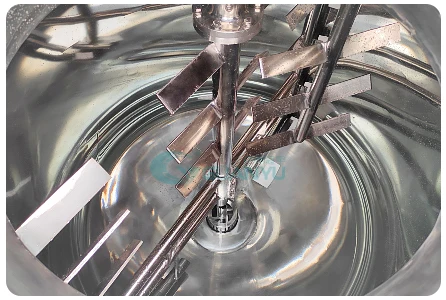

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high

quality products of different processes according to customer requirements.

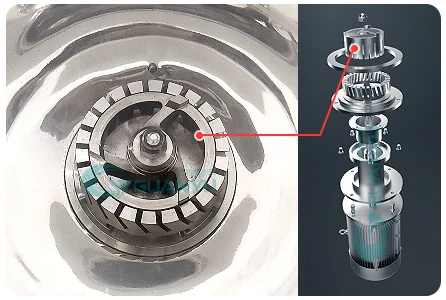

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis

soluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion

and shorten production period.

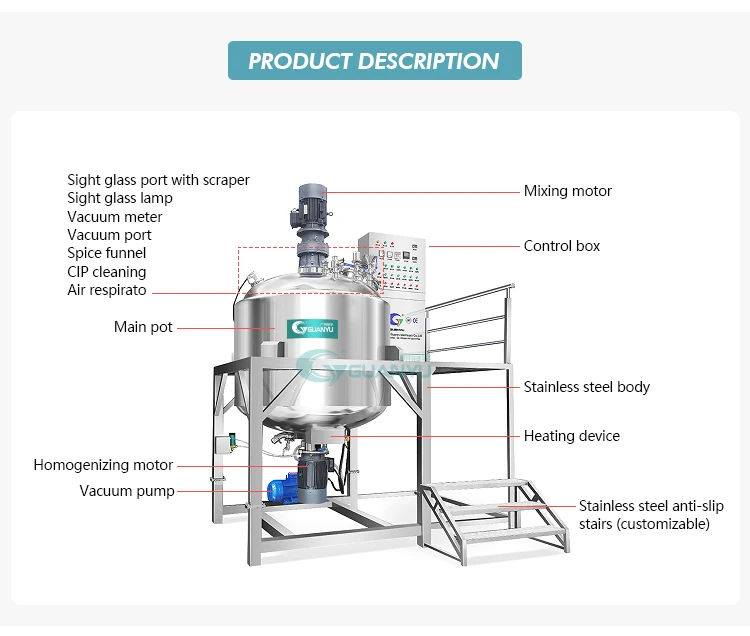

◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which

fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric

heating. Easy to discharge , bottom direct discharge or by transfer pump.

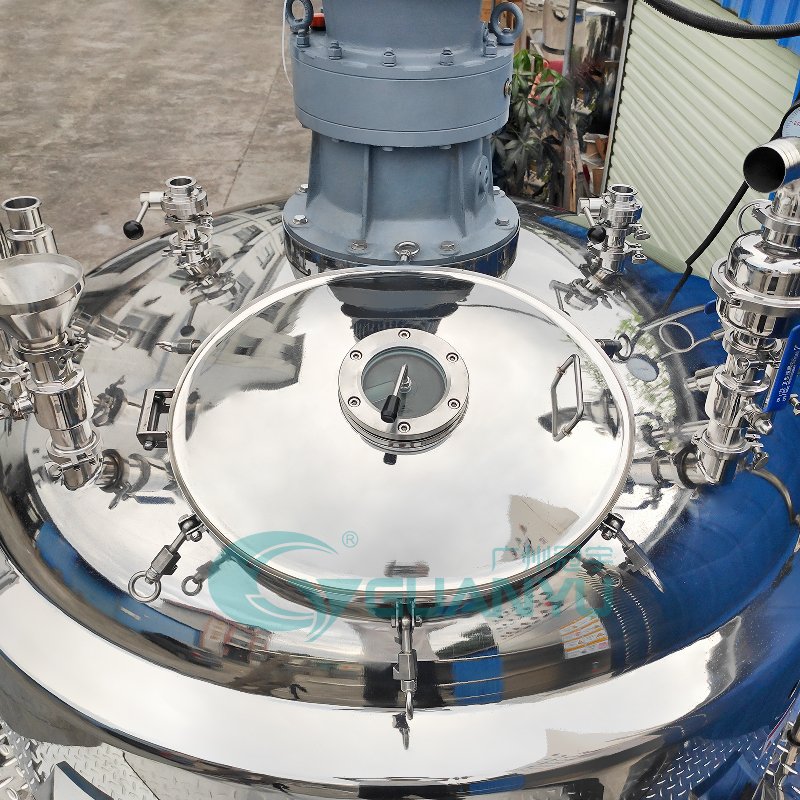

Mixing paddle

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Vacuum Pumps

Discharge

(if necessary, a discharge pump can be equipped to directly extract materials)

Console

working timing, vacuum extraction, interlayer heating, etc.

(PLC control is optional)

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Reviews

There are no reviews yet.