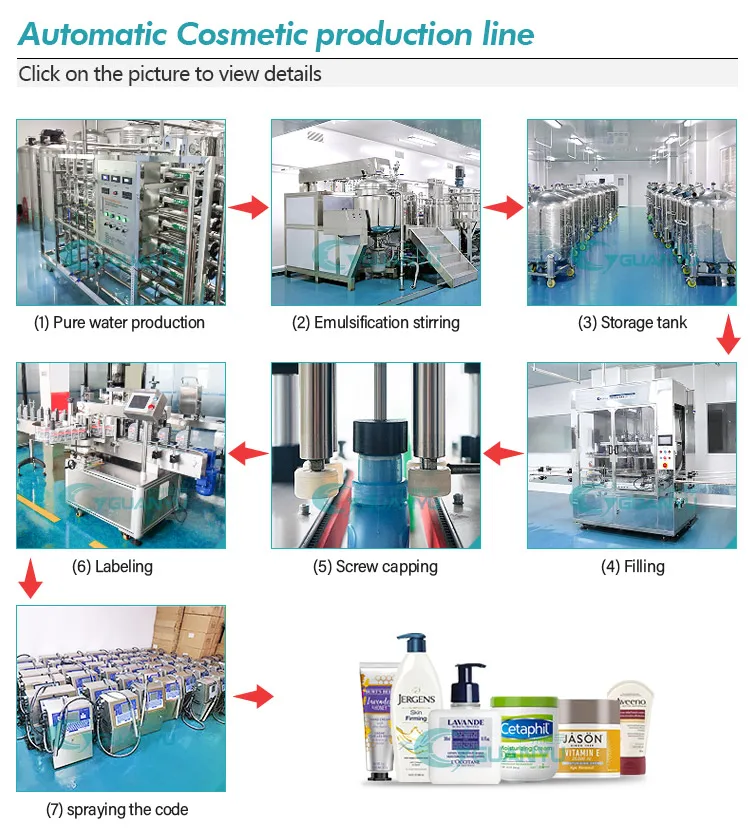

20L 50L Chemical Mixing Machinery Ointment Vacuum Emulsifying Cosmetic Mixer Creams Homogenizer Vacuum Emulsifier

Dear all, thank you for visiting. Hope you can find what you need here. For a more efficient communication, please refer to thefollowing question when sending the inquiry.

1. What is your product? (Cosmetics,liquid soap, or shampoo or ?) 2. What is the capacity you need? 3. Is your product highly corrosive? 4. Does the product needs heating when mixing?

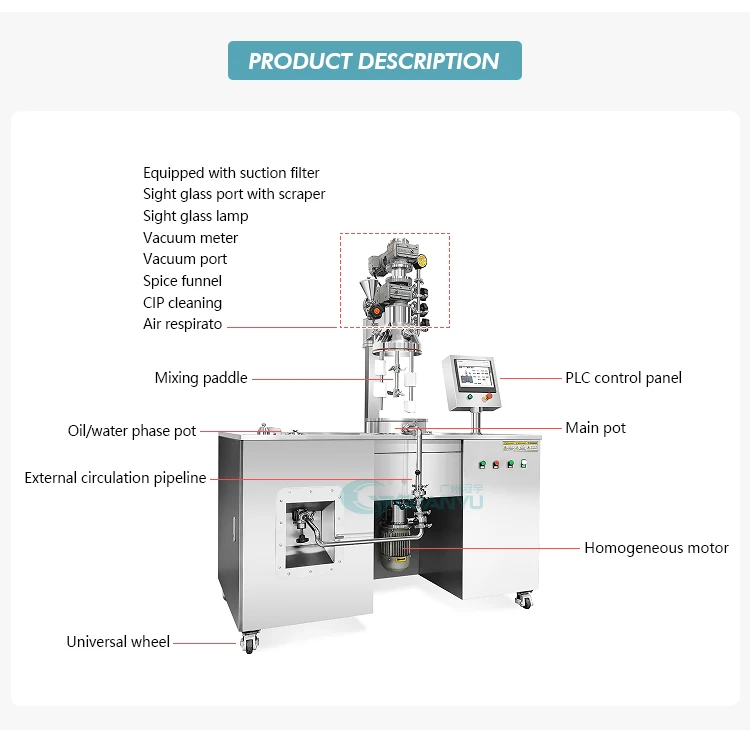

Products Description

Specification | Working Volume(L) | Heating Method(optional) | Dimension(L*W*H)(m) | Weight(kg) |

GYE-50 | 50 | Electric heating or steam heating | 2.6*2.4*2 | 650 |

GYE-100 | 100 | 2.8*2.5*2.2 | 850 | |

GYE-200 | 200 | 3*2.8*2.3 | 1100 | |

GYE-500 | 500 | 3.3*3*2.5 | 1500 | |

GYE-1000 | 1000 | 4.2*3.5*3.8 | 2500 |

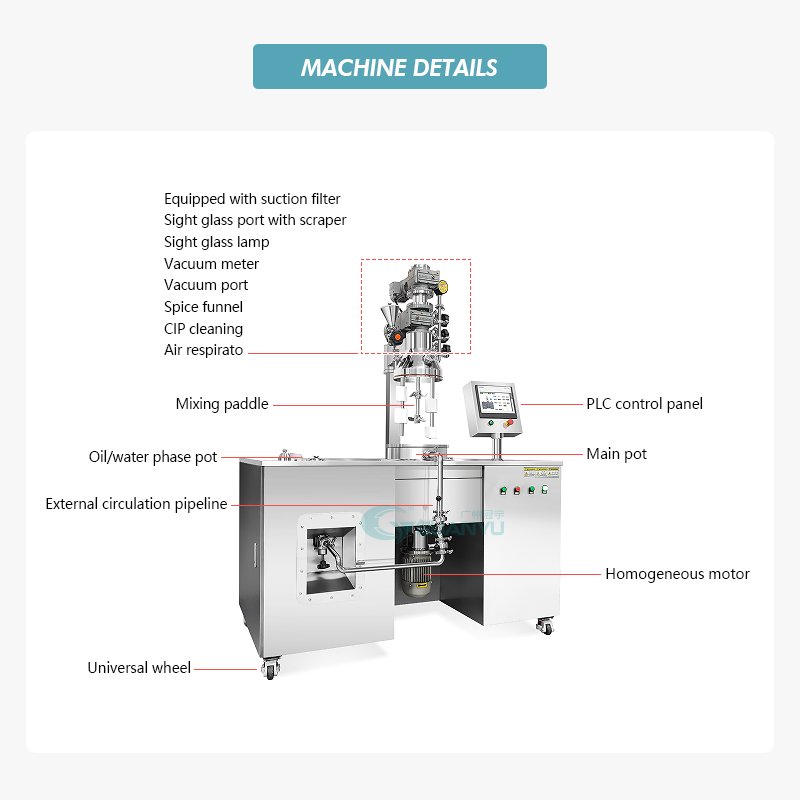

Features1. Vacuum defoaming function can make the materials meet the requirement of being aseptic. 2. The main boiler lid adopts the lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler adopts a tilting discharge.3. The main tank can be heated and cooled with an electric heating function.4. Adopts imported electric appliances which can meet international standards.5. Contacted parts are made of SS316L, the wall scraper is made of PTFE.

IntroductionVacuum Emulsifier equipment refers to the equipment professionally used for high-speed shearing, dispersion and mixing of materials. It can make the material fully emulsified and fine, mixed evenly, and remove air bubbles in the production process.Professionally used for cosmetic cream materials and chemical cream materials.

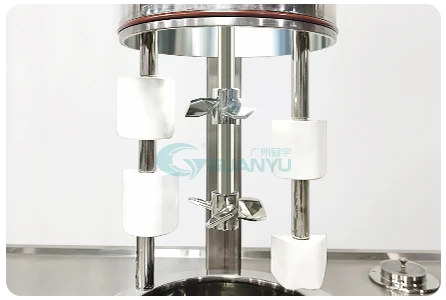

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

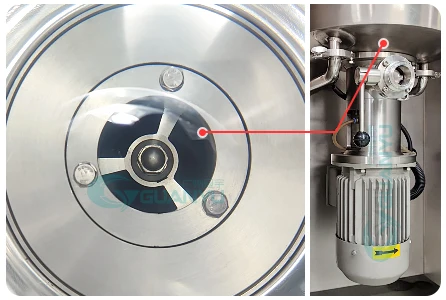

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Accessories

Material SS316, thickness 6 mm,Equipped with suction filter, drain valve, vacuum port, sight glass lamp, sight glass port with scraper, spice funnel, CIP cleaning, Air respirator

Oil-water pot

The water phase tank and oil phase tank of the pre-treatment system preheat and disperse the raw materials, then transfer them to the main tank, and start homogeneous mixing to emulsify the materials

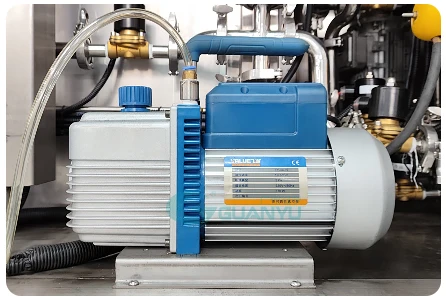

Vacuum Pumps

Under the vacuum environment, the emulsification pot can discharge foam when the materials are mixed, thus improving the quality of the materials to be treated. Vacuum deaeration process can ensure the sterility of materials

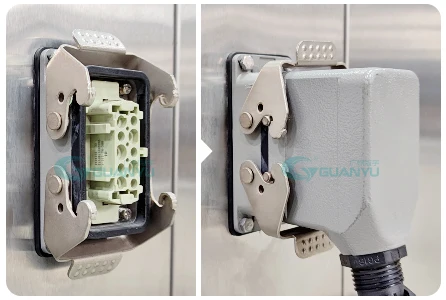

Aviation plug

The aviation plug is waterproof, dustproof and anti-falling, making the production process more convenient and safer to use.

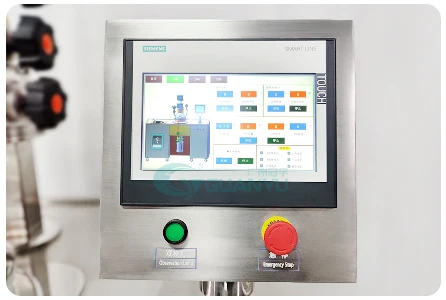

Console

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, etc.

working timing, vacuum extraction, interlayer heating, etc.

Console

We will design drawings according to your requirements and provide one-stop solutions.

Reviews

There are no reviews yet.