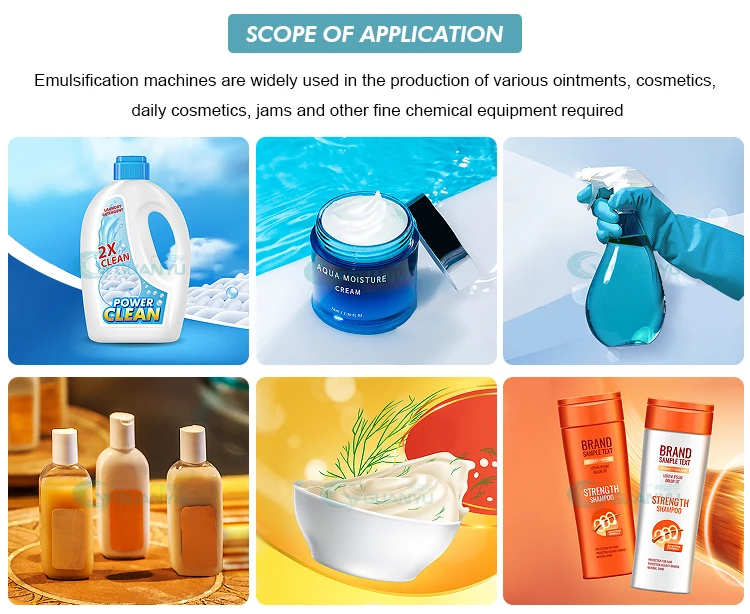

Vacuum Emulsifying Machine Vacuum Homogenizing Emulsification Blender Mixer Tank For Cosmetic Cream , skin cream,lotion

Products Description

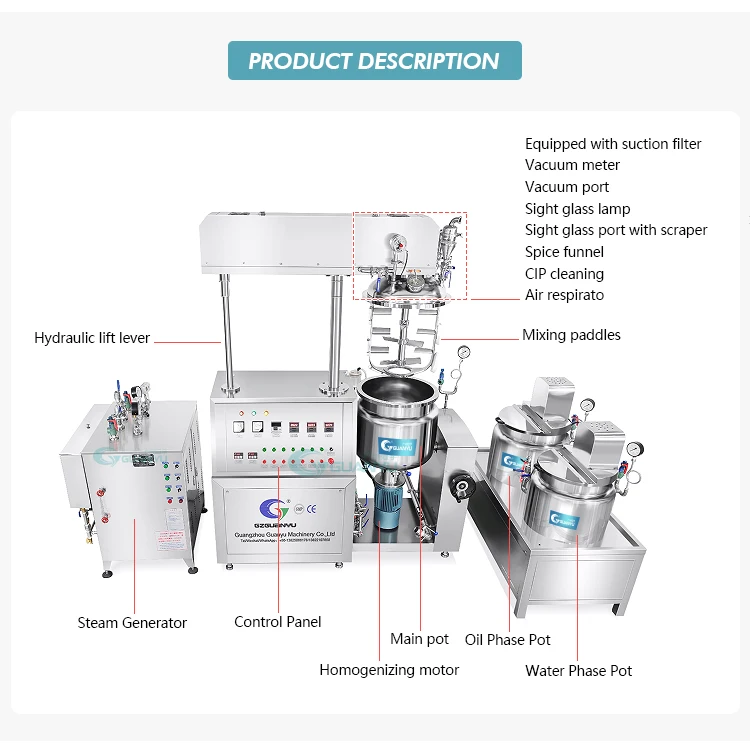

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Heating

Electric heating or steam heating can be selected, and the material is heated through the interlayer to achieve the ideal

stirring and emulsification state.

stirring and emulsification state.

Oil-water pot

The water phase tank and oil phase tank of the pre-reatment system preheat and disperse the raw materials, then ransfer

them to the main tank, and start homogeneous mixing to emulsify the materials

them to the main tank, and start homogeneous mixing to emulsify the materials

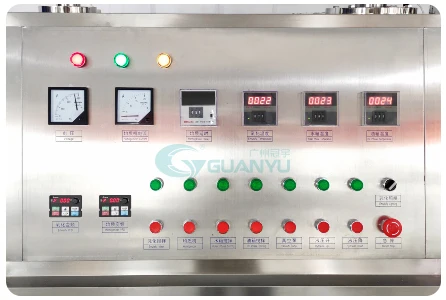

Console

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, etc.

(PLC control is optional)

working timing, vacuum extraction, interlayer heating, etc.

(PLC control is optional)

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

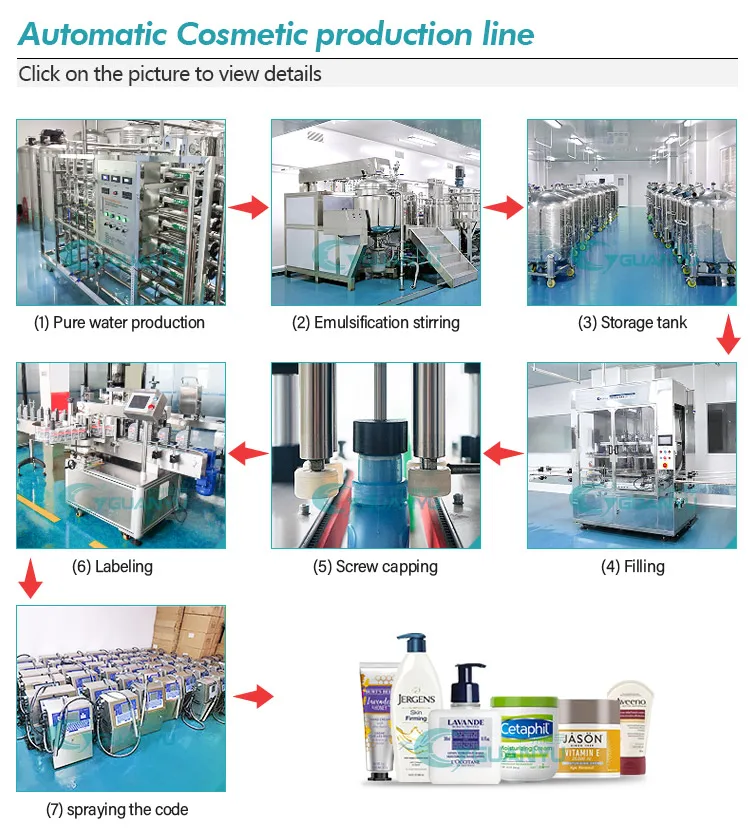

The Industrial Cosmetic Mixer Composition:Vacuum Homogenizer emulsifying mixer machine Vacuum Homogenizer emulsifying mixer machine is mainly composed of water pot,oil pot,emulsifying pot, vacuum system, lifting system(optional) ,electric control system(PLC is optional) and operation platform, etc.Vacuum Homogenizer Usage and Application:Our industrial food mixer is mainly applied in such industries as daily chemical care products, biopharmaceutical industry, foodindustry, paint and ink, nanometer materials, petrochemical industry, printing and rubber, electrics and electronics and finechemical industry etc., the emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Reviews

There are no reviews yet.