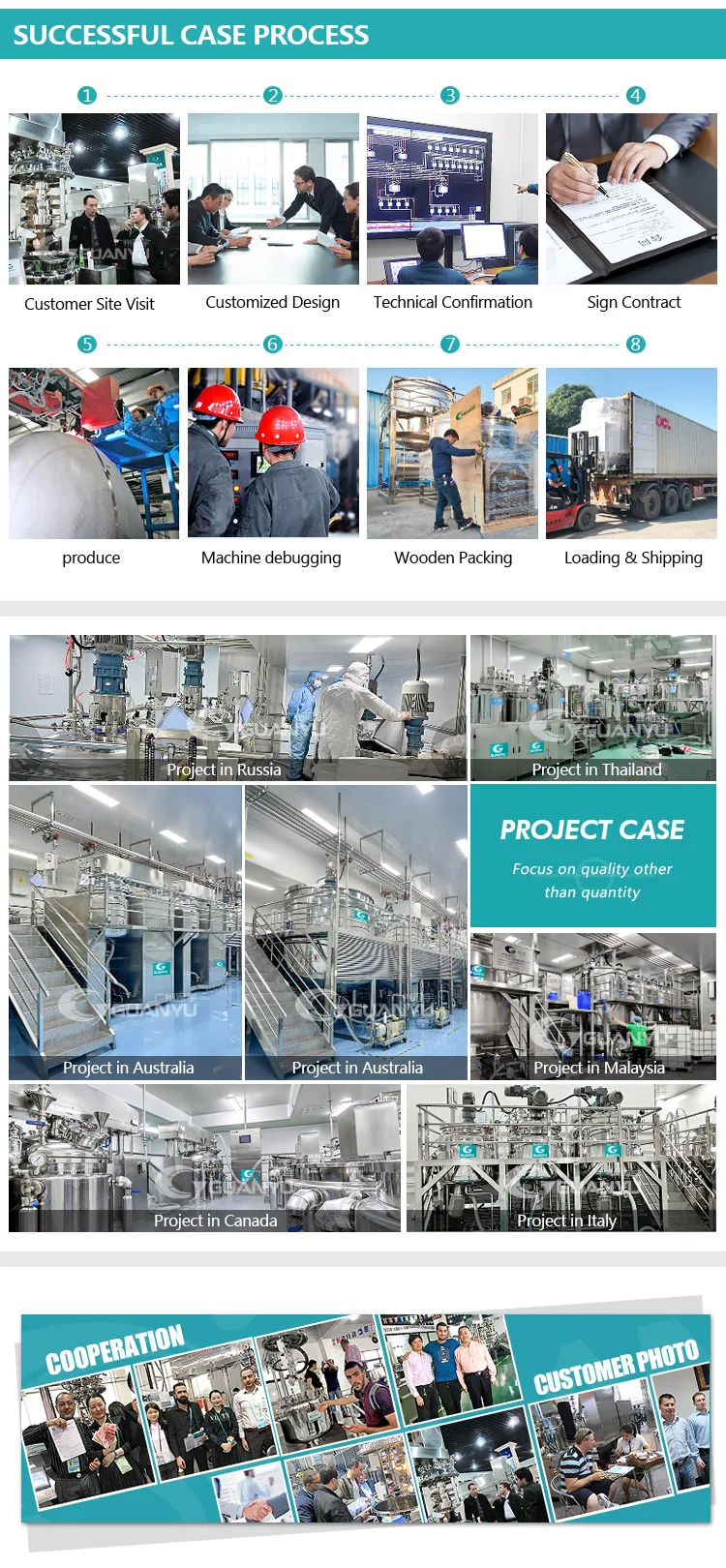

300L Automatic Vacuum High Shear Cream Paste Emulsifying Homogenizer Mixer Machine High Speed Dispenser Tank

Products Description

1,The triple mixing adopts the imported frequency inverter for speed adjustment,which can meet different technological demands.2,The homogenizing structure is made through German techology. The machine adopts the improted double-end mechanical sealeffect.The maximum emulsifying rotation speed can reach 3500rpm and the high shearing fineness can reach 0.2-5um.3,The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking canavoid dust.4,The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler canadopt tilting discharge.5,The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish whcih meet the GMP standard.6,According to process requirement, the tank body can heating and cooling the electric heating.7,To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the internationalstandards.

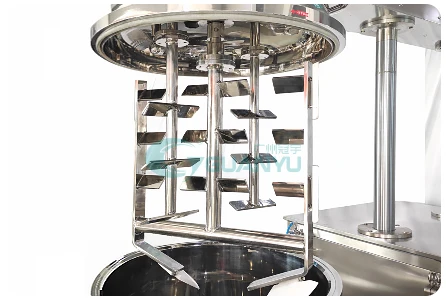

Mixing paddle

Frequency conversion speed regulation 0-63r/min, the shape of the blades will be designed according to your materials.

Title goes here

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

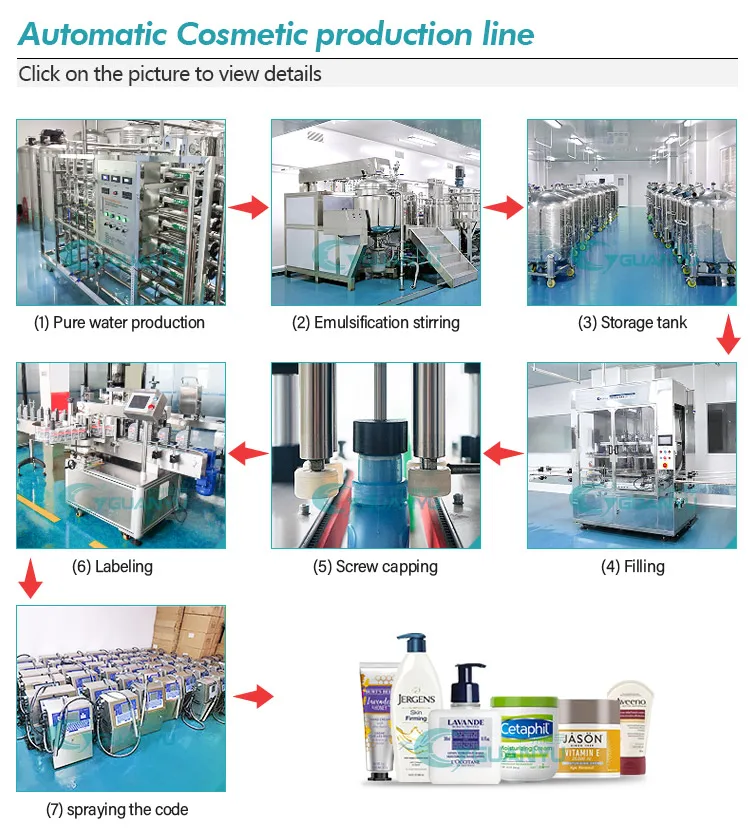

Oil-water pot

Pre-treatment System Water phase and oil phase pot to pre-heat and disperse the raw materials, then transfer them to

main pot to begin production.

main pot to begin production.

Console

The control panel displays and controls the equipment temperature, mixing, homogenization, pressure data, etc.

in real time.

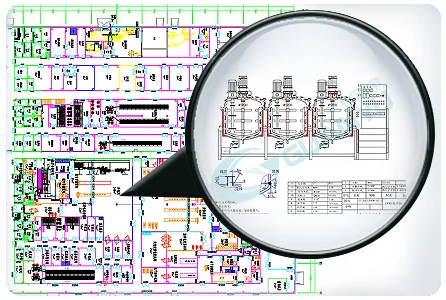

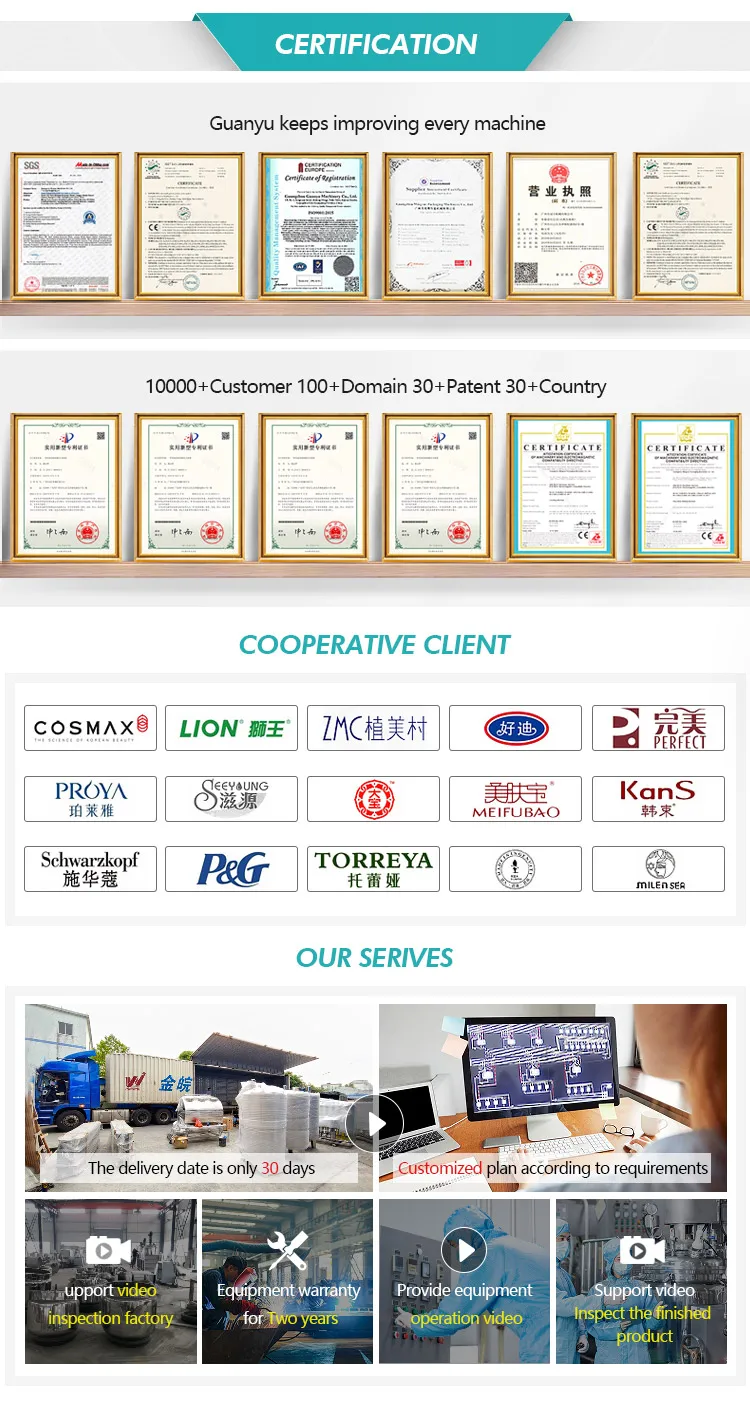

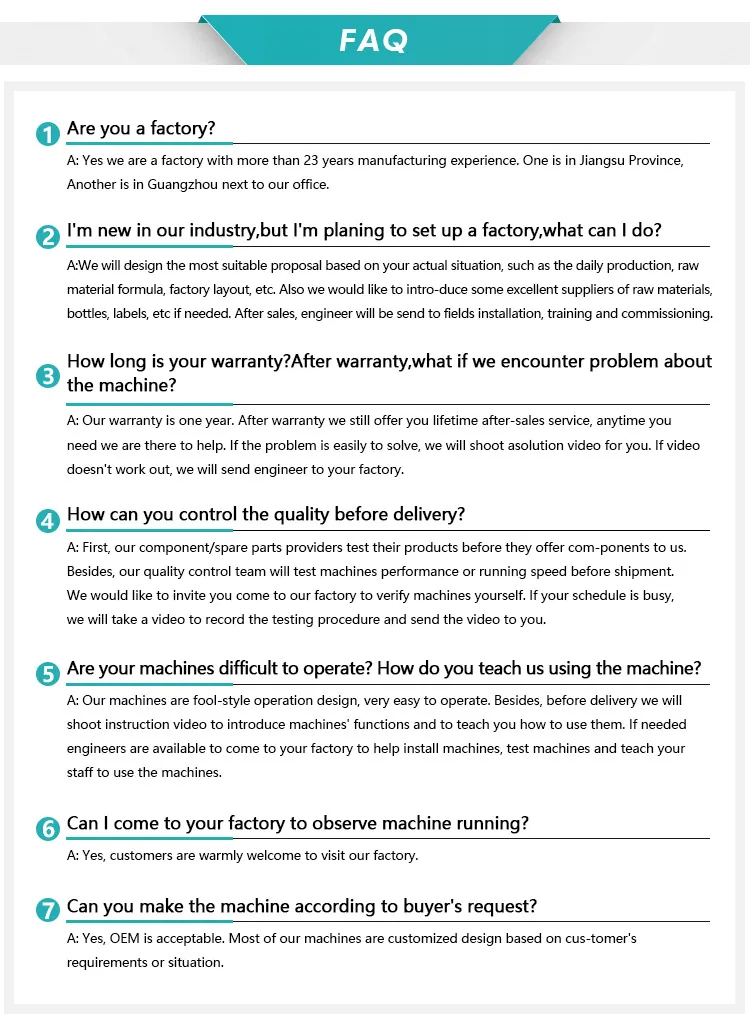

Service

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

Reviews

There are no reviews yet.