Cosmetic Cream Production Homogenizer Vacuum Emulsifier Mixer Ointment Making Equipment Lotion Mixing Machine With Heating

Products Description

Introduce:Structure:Stainless steel mixing tanks are widely applied in the beverage, food, dairy, chemical and process industries usedas blender tank, buffer tank and storage tank, which cleanable to sanitary standards .1.Capacity :100-20000L 2.Single layer/ double layers/ three layers3.Motor power:0.75-5.5kw4.Materials are all sanitary stainless steel .5.Humanized structure design and easy to operate .6.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation .Configuration of tank :1.Quick open manhole .2.Various types of CIP cleaners .3.Fly and insect resistant sanitary breathing cover .4.Adjustable triangular bracket .5.Dismountable materials input pipe assembly .6.Thermometer (According to customer requirements ).7.Ladder (According to customer requirements).8.Paddle blender .9.Liquid level meter and lever controller (According to customer requirements) .10.Eddy-proof board .

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Oil-water pot

Pre-treatment System Water phase and oil phase pot to pre-heat and disperse the raw materials, then transfer them to main pot to begin production.

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

Console

The control panel displays and controls

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

Electric box

Use internationally renowned brand

components to ensure the quality of the

equipment and longer service life

components to ensure the quality of the

equipment and longer service life

Service

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

All functions can be customized according to your requirements.

In the past 26 years, we have grown together with our customers and provided professional and high-quality manufacturing equipment to users at home and abroad.

They are leaders in various fields, such as: cosmetics, food, chemical industry. We care about every detail of the manufacturing process and have a complete and strict manufacturing process to create first-class equipment.

We have a professional after-sales service team that can escort your production and manufacturing. We always put customer satisfaction and product quality first, and we firmly believe that we have a long-term cooperative relationship with each other.

Product configuration

Specification

item | value |

Mixer Type | Homogenizer |

Barrel Volume (L) | 200 |

Material Processed | Plastics, Chemicals, Food, Cosmetic |

Max. Loading Volume (L) | 200L |

Range of Spindle Speed(r.p.m) | 0r.p.m – 3200r.p.m |

Weight (KG) | 1600KG |

Material | SUS304, SUS316 |

Condition | New |

Product Type | Cosmetic Chemical Food |

Application | Viscous Fluid |

Additional Capabilities | Heating |

Place of Origin | China |

Guangdong | |

Brand Name | Guanyu |

Voltage | |

Power (kW) | 7.5kW |

Warranty | 1 Year |

Key Selling Points | Automatic |

Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Cosmetic Factory, Chemical Industry |

Showroom Location | Thailand |

Marketing Type | Ordinary Product |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Warranty of core components | 1 Year |

Core Components | Motor, Pressure vessel, Pump, PLC, Other |

Product name | Vacuum Emulsifying Mixing Machine |

Machine Type | Mixer |

Material | Stainless Steel 304 / SUS316L |

Jacket | 3 Layers 2 Jackets |

Speed control | Frequency Speed Regulation |

Application scope | Chemical Cosmetic Food |

Stirrer type | Paddle Mixer |

Control | PLC+ Touch Screen |

Heating method | Electric Steam Heating |

Feature | High Efficiency Easy Operation |

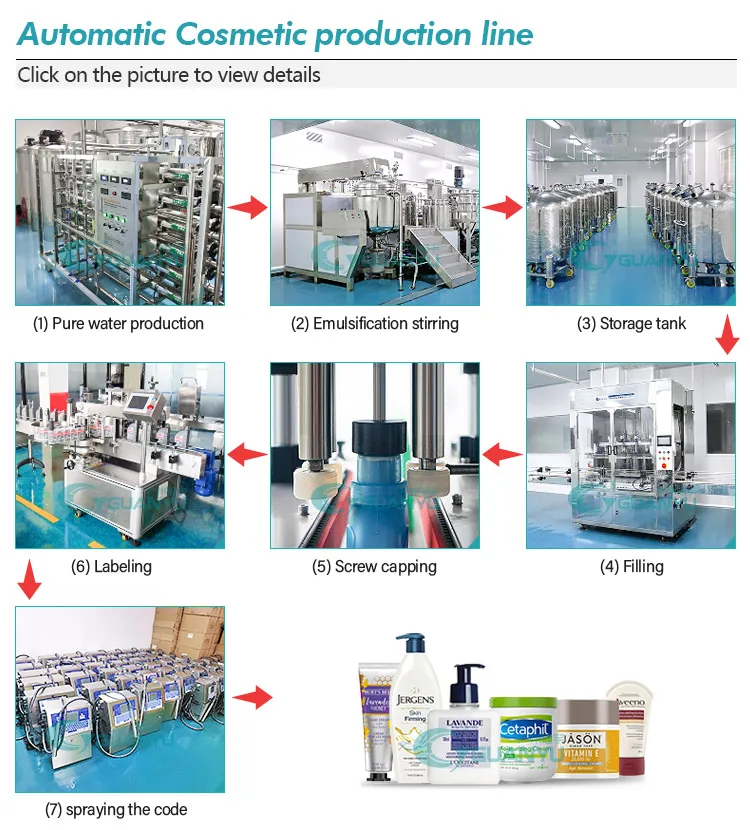

Successful case process

About Us

Guangzhou Guanyu Machinery Co., Ltd. was established in 1997.It devotes in the development, Manufacture and installation of the foodstuff, chemical, cosmetic and he pharmaceutical facility and equipment, water treatment equipment and so on. With the advanced technology, production and inspection equipment, and the specialized processes .We have been a professional equipment manufacturer and provided kinds of the equipment based on the market requirement.

Guangzhou Guanyu Co., Ltd Works has earned a good reputation and trust from clients for timely delivery, reliable quality and good after-sales service. We keep a firm principle of abiding by contracts and quality first” Meanwhile, we always take clients as our top concern and strive to serve them well.

For satisfying the domestic and international customers, we adhere to our principle “Quality the first, Technology leading, social and environment care and continuous development ” to meet the criteria of the ISO9001 and good after- has owned us a good reputation in the industry and firmed business relationship and friendship with all our customers.

We warmly welcome the customers at home and abroad to visit our company and choose our products!

Guangzhou Guanyu Co., Ltd Works has earned a good reputation and trust from clients for timely delivery, reliable quality and good after-sales service. We keep a firm principle of abiding by contracts and quality first” Meanwhile, we always take clients as our top concern and strive to serve them well.

For satisfying the domestic and international customers, we adhere to our principle “Quality the first, Technology leading, social and environment care and continuous development ” to meet the criteria of the ISO9001 and good after- has owned us a good reputation in the industry and firmed business relationship and friendship with all our customers.

We warmly welcome the customers at home and abroad to visit our company and choose our products!

Packing & Delivery

After the equipment has been inspected and tested, our after-sales team will pack the equipment in wooden boxes to ensure that no damage is caused to the equipment during transportation.

Certifications

FAQ

1.Are you a factory?

A: Yes we are a factory with more than 23 years manufacturing experience.One is in Jiangsu Province, Another is in Guangzhou next to our office.2.I’m new in our industry,but I’m planing to set up a factory what can I do?A:We will design the most suitable proposal based on your actual situation such as the daily production, raw material formula,factory layout etc. Also we would like to introduce some excellent suppliers of raw materials,bottles. labels. etc if needed.After Sales engineer will be send to fields installation training and commissioning.3.How long is your warranty?After warranty what if we encounter problem about the machine?A: Our warranty is one year. After warranty we still offer you lifetime after-sales service,anytime you need we are there to help. If the problem is easily to solve we will shoot a solution video for you. If video doesn’t work out we will send engineer to your factory.4.How can you control the quality before delivery?A: First,our component/spare parts providers test their products before they offer components to us. Besides, our quality control team will test machines performance or running speed before shipment. We would like to invite you come to our factory to verify machines yourself.If your schedule is busy, we will take a video to record the testing procedure and send the video to you.5.Are your machines difficult to operate? How do you teach us using the machine?A: Our machines are fool-style operation design very easy to operate. Besides before delivery we will shoot instruction video to introduce machines functions and to teach you how to use them. If needed engineers are available to come to your factory to help install machines test machines and teach your staff to use the machines.6.Can I come to your factory to observe machine running?A: Yes, customers are warmly welcome to visit our factory.7.Can you make the machine according to buyer’s request?A: Yes, OEM is acceptable. Most of our machines are customized design based on customer’s requirements or situation.

Reviews

There are no reviews yet.