liquid soap making machine detergent vacuum homogenizer mixer machine shampoo mixing tank stirring vessel gel agitator tank

Products Description

◭Vacuum emulsifying mixer tank machine is consist of vacuum emulsifying main tank, oil pot ,water pot, hydraulic lifting system tile glue mixing machine(with or without),heating &cooling system,vacuuming system,PLc automatic control or manual button control system,etc.◭The scraper type agitator mixing adopts the frequency converter for speed adjustment , so that high quality products of differentprocesses according to customer requirements.◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolvemanyindissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energyconsumpion and shorten production period. High Shear Homoegnizer adopts German Technology, 0~3500rpm variable speed, and maximumspeed can reach to 4500rpm,the shear degree is about 0.2~5um. tile glue mixing machine◭The tank body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing or tile glue mixing machinematte finish , which fully conforms to GMP requirements. tile glue mixing machine◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electricheating. Easy to discharge , bottom direct discharge or by transfer pump. tile glue mixing machine tile glue mixing machine◭The emulsifying main tank ,it is vacuum design ,the maximum vacuum degree is -0.09Mpa. ◭We can choose hydraulic lifting ,it is easy for cleaning. or if factory has limited space,we can advise to fixed type, the topcover can not lifted,but there is pressure manhole,we can open it to check the tank inside . ◭Oil pot and water pot as pre-heating and pre-mixing,it is necessary for batch production,it efficiently save the preparationtime.◭We can choose PLC automatic control system ,or manual button control box,it depens upon your demand.

Model | Working Volume(L) | Mixing power(kw) | Mixing speed(r/min) | Homogenizing power(kw) | Homogenizing speed(r/min) | Heating method |

GYE-5 | 5 | 0.37 | 0~63 | 0.75 | 0~3500 | Electric |

GYE-50 | 50 | 1.1 | 0~63 | 2.2 | 0~3500 | Electric |

GYE-100 | 100 | 2.2 | 0~63 | 3~4 | 0~3500 | Electric |

GYE-200 | 200 | 2.2 | 0~63 | 4~5.5 | 0~3500 | Steam heating Or Electric heating |

GYE-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3500 | |

GYE-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3500 | |

GYE-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3500 | |

GYE-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3500 | |

GYE-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3500 | |

GYE-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3500 |

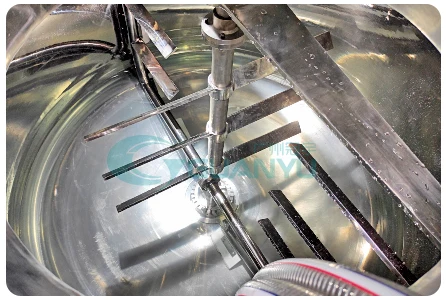

Mixing paddle

Frequency conversion speed regulation 0-62r/min, the shape of the blades will be designed according to your materials.

Homogenizer

Frequency conversion speed regulation 0-3000r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Hermetic vacuum

Defoaming throught the vacuum system can meet the requirements for the aseptic and high standard product.

Transportation

Equipped with a lifting platform, which

can be used to transport heavy materials

to the platform for the next operation.

can be used to transport heavy materials

to the platform for the next operation.

Console

The control panel displays and controls

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

the equipment temperature, mixing,

homogenization, pressure data, etc. in real

time.

( Optional PLC control )

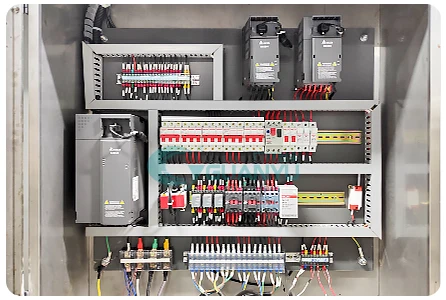

Electric box

Use internationally renowned brand

components to ensure the quality of the

equipment and longer service life

components to ensure the quality of the

equipment and longer service life

Service

We will design drawings according to your

requirements and provide one-stop solutions.

requirements and provide one-stop solutions.

Product configuration

About Us

Successful case process

Certifications

FAQ

Reviews

There are no reviews yet.