Picking the best vacuum emulsifying mixer helps your business do well. You need equipment that fits your cosmetic product’s needs. It should also help you reach your goals. Each ingredient, like how thick or heavy it is, changes how mixing works. Think about these key things:

What materials you want to mix

How strong you want the mixing to be

How much you need to make each time

If the mixer works with your product’s special parts

Support after buying and your budget

Getting help from experts makes finding the right mixer easy and useful.

Key Takeaways

Figure out what you need to make. Know what products you make and how much you need. This helps you pick the right mixer size and type.

Think about how thick your products are. Thick products need stronger mixers with special blade shapes to mix well.

Look at how hard your mixing process is. Find features like temperature control and easy cleaning to make work safer and faster.

Make sure the mixer works with your ingredients. This keeps your products good and helps the machine last longer.

Get help from experts. Talk to professionals to make your mixer fit your needs and get the best results.

Define Production Needs

To pick the right vacuum emulsifying mixer, you need to know what your business needs. Think about what you make, how much you make, and if your process is simple or hard. This helps you choose a machine that works for your business and helps you reach your goals.

Product Type & Viscosity

Start by thinking about what kind of product you make. Are you making creams, lotions, ointments, or emulsions? These are used in cosmetics, medicine, food, and cleaning products. Each one mixes in a different way. Viscosity means how thick your product is. Thick creams need stronger mixing and special blades. You need a vacuum homogenizing emulsifying mixer that can mix thick products well. This helps your product turn out smooth and even every time.

Tip: If your product is thick, pick a mixer with a strong motor and the right blade shape.

Batch Size & Output

Now, think about how much you make at one time. How much do you need to make each day or week? This tells you what size mixer you need. For example, if you make 500kg of face cream a day in two batches, your mixer should hold at least 250kg per batch. Make sure the mixer size matches your product. Thick products might need a bigger tank to mix well. Also, think about if your business will grow. A bigger mixer can help you make more in the future.

Feature | Description |

|---|---|

Machines made for your special process | |

Capacity | Small for testing, big for lots of products |

Versatility | Can mix many kinds of products and thicknesses |

Process Complexity

Last, think about how hard your process is. Do you need fast mixing, strong vacuum, or good temperature control? Look for things like easy cleaning, safety, and saving energy. Guangzhou Guanyu can make machines for any industry. Their mixers have main pots, vacuum parts, and heating controls. You can talk to their engineers to make sure the machine fits your needs.

Note: Custom machines help your mixer work for your business, no matter what kind of products you make.

Key Features of Vacuum Emulsifying Mixer

Homogenization & Emulsification

You want your products to be the same every time. Homogenization and emulsification are very important for quality. Homogenization makes particles smaller. This helps creams and lotions feel smooth. Emulsification mixes things like oil and water together. It keeps them from separating.

New vacuum emulsifying mixers work even better now. They use new ways to mix and keep particles safe. By 2025, new designs will make mixing easier. The latest vacuum homogenizer has three layers of stainless steel. This makes it strong and clean. You can pick electric or steam heating. The mixer stirs in two directions at once. This helps mix everything well. The bottom homogenizer moves the mix around. It helps with hard recipes in cosmetics and medicine.

Aspect | Homogenization | Emulsification |

|---|---|---|

Particle Composition | Makes particles smaller and even. | Mixes liquids into one stable blend. |

Stability | Can separate after some time. | Stops separation with special agents. |

Equipment | Uses high-pressure or rotor-stator homogenizers. | Uses high-shear mixers and vacuum emulsifying mixers. |

Applications | Used for evenness in food, medicine, and cosmetics. | Needed for stable things like lotions and sauces. |

Tip: Good homogenization and emulsification give you great mixing results every time.

Vacuum System

The vacuum system is a very important part. It takes out air bubbles from your mix. This stops problems like separation or spoilage. It helps your product stay good and last longer. When you use a vacuum homogenizing emulsifying mixer, you make a vacuum in the tank. The system pulls out air and keeps bubbles from coming back.

Function | |

|---|---|

Vacuum-resistant vessel | Holds the mix and stands up to vacuum pressure. |

High-speed homogenizer | Mixes and blends all the ingredients well. |

Scraping agitator | Stops stuff from sticking to the tank walls. |

Vacuum pump | Makes and keeps the vacuum to get rid of air bubbles. |

Heating and cooling system | Changes the mix’s temperature during the process. |

Electrical control system | Runs the mixer, vacuum, and stirring controls. |

The vacuum system helps your mix stay even and last longer. Modern tanks also help you mix fast when you need to.

Mixing Technology

Mixing technology is much better now. Today’s mixers can mix, heat, and vacuum all in one. This makes your job faster and easier. You can make batches quickly and get smooth mixes. The closed vacuum keeps air out. This helps your products stay fresh and look nice. Automatic cleaning makes it easy to keep the machine clean and safe.

Guangzhou Guanyu uses new technology and checks quality closely. Their machines work well and are very steady. You can trust their mixers for many recipes and needs.

Cosmetic Mixing Machine Options

You have many choices with Guangzhou Guanyu’s cosmetic mixing machines. Each model fits different business needs and goals.

Vacuum Emulsifying Mixers: These have three ways to mix, remove bubbles, and use a German system. You can change the speed and pick electric or steam heat. They work for many recipes.

Fixed Lifting Mixers: These mixers are steady for making batches. They are good for thick mixes and cost less.

Hydraulic Lifting Vacuum Emulsifying Mixers: These have special features like vacuum removal and exact speed control. They are great for hard jobs and top-quality products.

Note: You can ask Guangzhou Guanyu’s team for help. They will help you pick the best machine for your needs. This way, you get the best results easily.

Capacity & Compatibility

When you pick a vacuum emulsifying mixer, start with size and fit. These two things help you find the best machine for your needs. You want a mixer that matches your batch size. It should work with your ingredients. It should also help your business grow.

Ideal Vacuum Emulsifying Mixer Size

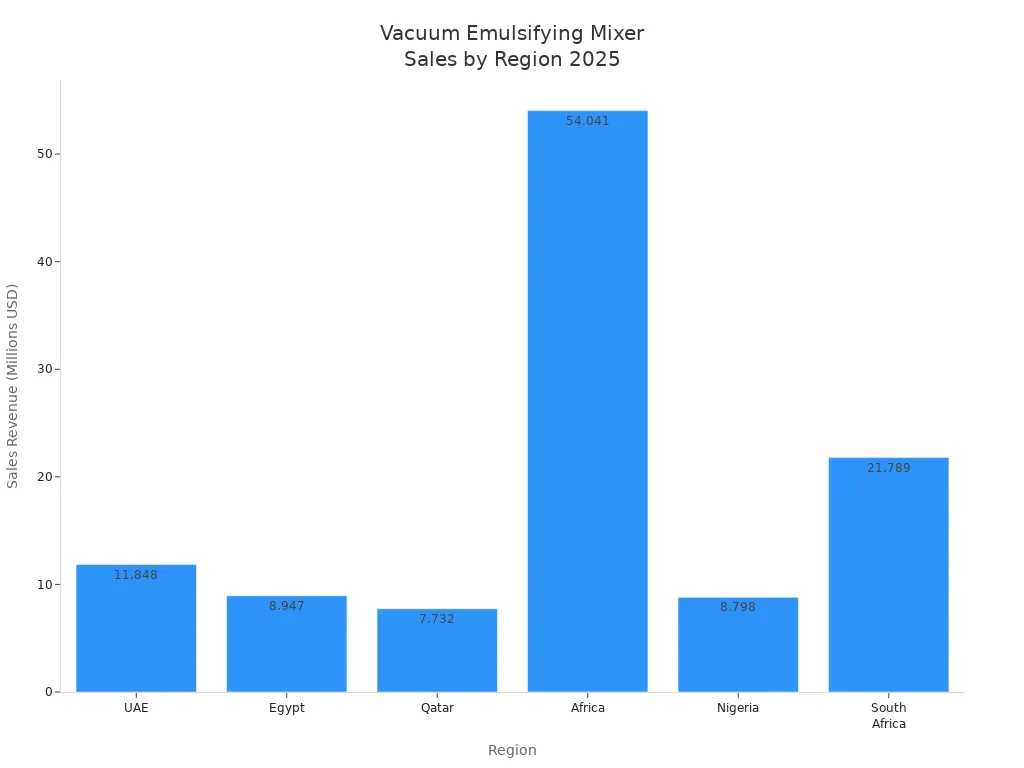

Pick a mixer size that fits what you make each day. If your mixer is too small, you will need to make more batches. If it is too big, you might waste power and supplies. Many companies look at sales numbers to see which sizes are best. The table below shows how different places spend money on mixers. This can help you see which sizes are popular.

Region | Sales Revenue (2025) | Growth Rate |

|---|---|---|

UAE | 4.749% | |

Egypt | $8.947 Millions | 3.635% |

Qatar | $7.732 Millions | 3.903% |

Africa | $54.041 Millions | 11.001% |

Nigeria | $8.798 Millions | 11.251% |

South Africa | $21.789 Millions | 11.658% |

Africa and South Africa have the most sales. This means many companies there buy bigger or newer mixers. When you plan, think about what you need now and later. The right mixer size helps you meet demand and work better.

Material Compatibility

Material compatibility is key for your mixer to last. You want your cosmetic mixing machine to work well with your ingredients. Here are some things to think about:

Material compatibility keeps your mixer strong and working well.

Stainless steel is great because it does not rust or break easily.

The mixing chamber shape, the space between rotor and stator, and blade shape all matter.

If you use strong chemicals or special ingredients, check if the mixer can handle them. This keeps your machine safe and your products good.

Tip: Always ask what materials are in your mixer. This helps you avoid trouble and keeps your work going well.

Customization Choices

Every business is different. Guangzhou Guanyu gives you many ways to change your vacuum emulsifying mixer. You can pick the size, speed, heating, and controls. These choices help you get the best results.

Customization Option | Benefit to Manufacturers |

|---|---|

Size | Meets specific production goals |

Mixing Speed | Enhances efficiency in production |

Heating Method | Improves product quality |

Control Systems | Provides flexibility in operations |

You can work with Guanyu’s engineers to make a mixer that fits your needs. Customization lets you try new recipes and work faster. Your products can be better and different from others. You get a machine that grows with your business and helps you reach your goals.

Automation, Safety & Compliance

Automation Levels

You can pick mixers with different automation levels. Automation helps you work faster and make fewer mistakes. Many mixers have features that make your job easier.

Programmable controls let you set how long and how fast to mix.

Sensors watch the temperature and pressure while mixing.

Batch control systems help you do the same thing every time.

Automated material handling puts ingredients in the mixer for you.

Recipe management software saves your favorite settings for each product.

These features help you work better and save money on workers. You finish more work in less time. Your business can grow without much extra effort.

Safety Features

Safety is very important when you use machines. Good vacuum emulsifying mixers have many safety features. Emergency stop buttons let you stop the machine quickly. Safety covers keep you safe from moving parts. Overload protection keeps the motor safe if something goes wrong. Temperature and pressure alarms warn you before trouble starts. These features help you feel safe and trust your equipment.

Tip: Always make sure your mixer has the safety features you need. This keeps your team safe and helps your work go smoothly.

Regulatory Standards

You must follow rules in cosmetics and medicine. These rules make sure your products are safe and good quality. The table below shows the main rules you need to know:

Industry | Regulatory Standards |

|---|---|

Pharmaceutical | Must follow FDA or EMA rules for safety, purity, and strength. Validation is needed. |

Cosmetics | GMP certification is important; machines must be easy to clean, safe, and good for cosmetic ingredients. |

When you pick a vacuum emulsifying mixer, check if it meets these rules. This helps your business avoid problems and keeps your products trusted. Guangzhou Guanyu makes machines that follow these rules and helps you stay compliant after you buy.

Value & Support

Good Quality Vacuum Emulsifying Machine

When picking a vacuum emulsifying mixer, you want it to be good. Experts look for signs that show the machine is high quality. You can use this table to check what matters most:

Key Indicator | Description |

|---|---|

Homogenization Effect | Makes droplet sizes between 200nm and 2um for better mixing. |

Quality of Final Product | Gives you smooth, shiny face cream every time. |

Structural Reliability | A strong build means it lasts longer and breaks less. |

Operational Convenience | Easy to use, so you work faster and make fewer mistakes. |

Look for these things when you compare mixers. They help you get the best results for your business.

After-Sales Service

Guangzhou Guanyu helps you after you buy your mixer. You get help with setting up, testing, and learning how to use it. This support makes sure you use your mixer the right way. Here is what you get:

Service Type | Description |

|---|---|

Equipment Installation | Experts put your machine together at your place. |

Commissioning | They check if everything works before you start making products. |

Training | You learn how to use and take care of your mixer. |

This help keeps your work going well and stops problems before they start.

Warranty & Maintenance

Every mixer from Guangzhou Guanyu comes with a two-year warranty. The company will also help you fix your mixer for life. You should check your mixer often to stop problems like leaks or broken parts. Experts say you should get your mixer serviced every five years. Taking care of your mixer helps it last longer and work better.

Tip: If you check your mixer often, you can find problems early and keep it working well.

Expert Consultation

You can talk to Guanyu’s engineers whenever you need help. They help with setup, training, and any questions you have. If you want to try new recipes or need help with a different mixer, they will guide you. Their help makes sure your mixer always works for your business.

To pick the best vacuum emulsifying mixer for your cosmetic business, do these things: First, think about what you make and how you make it. Next, look at how much room and money you have. Then, find machines that can make good lotions and creams. Also, think about how you might need to make more in the future.

When your mixer matches your needs, you can make smooth and shiny face cream each time. Getting help from experts makes sure you get great results and your mixer lasts a long time.

FAQ

How do you know which mixer size fits your business?

You should check your daily or weekly production needs. Pick a mixer that matches your largest batch size. If you plan to grow, choose a slightly bigger model. This helps you avoid frequent upgrades.

Can you use one mixer for different products?

Yes, you can use one mixer for many products. Make sure the mixer has the right blades and settings for each recipe. Clean the machine well between batches to prevent mixing ingredients.

What maintenance does a vacuum emulsifying mixer need?

You should clean the mixer after each use. Check for leaks or loose parts every week. Schedule a full service every year. Regular care keeps your machine working well and helps it last longer.

Does Guangzhou Guanyu offer training for new users?

Yes, you get training when you buy a mixer. Guanyu’s engineers show you how to use and care for your machine. You can ask questions during setup or later if you need help.

What support do you get after buying a mixer?

You receive a two-year warranty and lifelong maintenance. Guanyu’s team helps with installation, repairs, and spare parts. You can contact them anytime for expert advice or technical support.

**mindvault**

Mind Vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.