Vacuum emulsifying mixing uses a sealed system to blend and emulsify ingredients under vacuum. You often see this process in cosmetics, pharmaceuticals, and food production because it protects sensitive materials and creates smooth, stable products. Look at the table below to see how vacuum emulsifying stands out compared to other mixing methods:

Feature | Vacuum Emulsifying Mixer | Homogenizer |

|---|---|---|

Shear Force | Gentle, protects ingredients | High, may damage sensitive materials |

Efficiency | Fast, ideal for small batches | Faster for large-scale production |

Air Bubble Control | Removes air for better texture | May introduce air bubbles |

Guangzhou Guanyu leads the way with advanced Vacuum Emulsifying Mixers, trusted by manufacturers worldwide.

Key Takeaways

Vacuum emulsifying mixers blend liquids like oil and water in a sealed, low-pressure environment to create smooth, stable products without air bubbles.

This process improves product quality by removing air, protecting sensitive ingredients, and producing consistent textures in cosmetics, food, and medicines.

Key parts of the mixer include a stainless steel vessel, a vacuum system to remove air, and a homogenizer that breaks down particles for even mixing.

Using vacuum emulsifying mixers saves time, reduces waste, and extends product shelf life by preventing oxidation and improving stability.

Regular cleaning and maintenance keep the mixer safe and efficient, while customization options help meet specific production needs and boost performance.

Vacuum Emulsifying Basics

Definition

You use vacuum emulsifying when you need to mix two or more liquids that do not usually blend, like oil and water. This process happens inside a special mixer that creates a vacuum, or low-pressure environment. The vacuum draws the liquids into the mixing chamber and removes air bubbles. You get a smooth, stable mixture because the machine uses high-speed blades and strong shearing forces. These mixers often include heating and cooling features, so you can handle thick or solid ingredients easily. You find vacuum emulsifying in many industries because it makes mixing faster and improves product quality. The process helps you create creams, lotions, sauces, and medicines that look and feel the same every time.

Note: Vacuum emulsifying mixers can handle vessel sizes from 1 liter to 10,000 liters, making them suitable for both small labs and large factories.

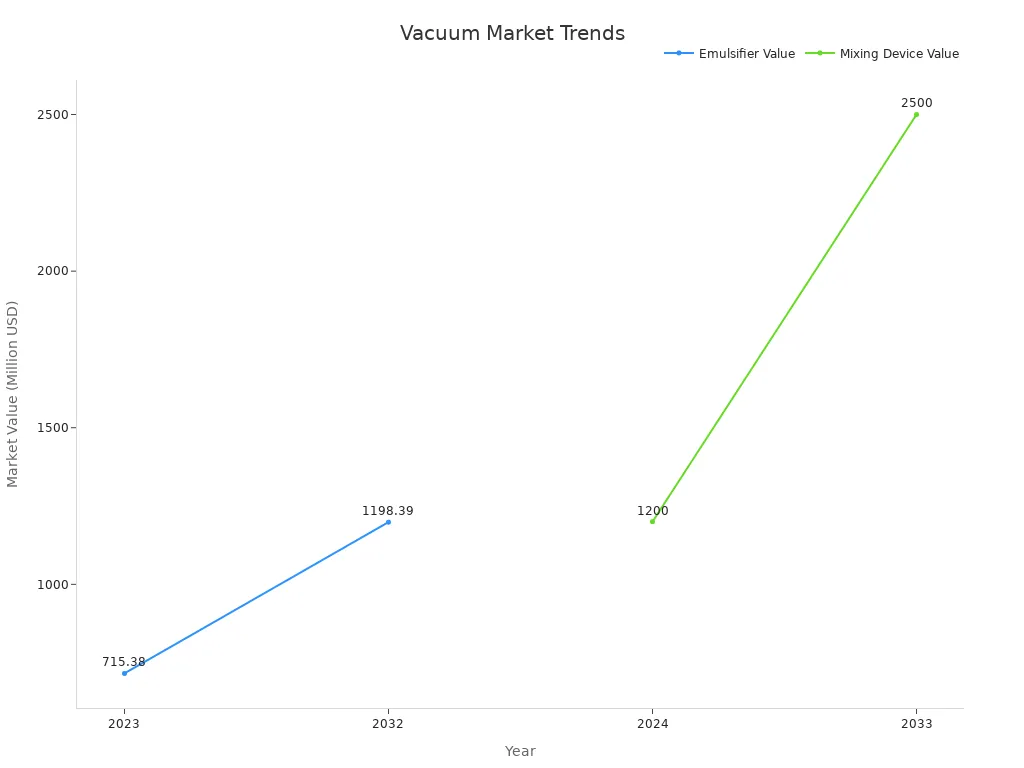

The market for vacuum emulsifying machines keeps growing as more companies want better mixing technology. Look at the table below to see how important this process has become:

Metric | Value (Year) | Forecast / CAGR |

|---|---|---|

Vacuum Emulsifying Machine Market Value | USD 1,198.39 million (2032) | |

Growth Rate (Vacuum Emulsifying Market) | N/A | CAGR 5.90% |

Vacuum Mixing Devices Market Value | USD 1.2 billion (2024) | USD 2.5 billion (2033) |

Growth Rate (Vacuum Mixing Devices) | N/A | CAGR 9.2% (2026-2033) |

Key Regional Markets | North America, Asia Pacific | Highest growth in Asia Pacific |

Applications

You see vacuum emulsifying used in many industries because it works well with different materials and products. Here are some common applications:

You can process thick creams, lotions, and gels in cosmetics manufacturing.

You can blend medicines, ointments, and syrups in the pharmaceutical industry.

You can mix sauces, dressings, and dairy products in food production.

You can handle polymers, slurries, and powders in chemical processing.

You can use vacuum-assisted mixing for delicate or hazardous materials, reducing heat and shear damage.

Vacuum emulsifying helps you achieve even mixing, better texture, and longer shelf life for your products. Many companies choose this process to improve efficiency and avoid problems like air bubbles or uneven blending.

Mixer Components

When you look at a vacuum emulsifying mixer, you see several important parts working together. Each part plays a key role in making sure your products come out smooth and stable every time. Let’s break down the main components you will find in advanced machines like the Guangzhou Guanyu Vacuum Emulsifying Mixer.

Mixing Vessel

The mixing vessel is where you load your ingredients. Modern vessels use high-quality stainless steel, which keeps your products safe and easy to clean. You get a triple-layer design that helps control temperature and keeps heat even. Many vessels have hydraulic lifting covers, so you can clean and maintain them with less effort. Safety features like pressure relief systems protect you and your team. You can also connect the vessel to digital systems for real-time monitoring. This makes your work easier and helps you keep track of every batch.

Tip: A user-friendly control panel lets you adjust speed and temperature quickly, so you always get the right mix.

Vacuum System

The vacuum system removes air from the vessel before mixing starts. This step is important in the vacuum emulsifying process because it stops bubbles from forming in your product. The system uses sensors and feedback controls to keep pressure steady. You get better texture and longer shelf life because the vacuum system keeps the pressure uniform. Many factories report less waste and higher product quality when they use this technology.

Vacuum systems keep pressure stable for consistent results.

Automated controls reduce mistakes and make your workflow smoother.

You get better detail and fewer defects in your final product.

Homogenizer

The homogenizer is the heart of the vacuum emulsifying mixer. It uses a high-shear rotor-stator system to break down particles and blend liquids that do not mix easily. This creates fine, stable emulsions with small droplet sizes. Studies show that high-pressure homogenizers and micro-jet systems give you the best results for stability and texture. You can adjust the speed from 0 to 80 meters per minute, which helps you handle different recipes.

Here’s a quick look at the advanced features you get with Guangzhou Guanyu’s Vacuum Emulsifying Mixer:

Feature | Details |

|---|---|

Homogenization | High-shear rotor-stator system for fine, stable emulsions |

Vacuum System | Automated vacuum for air bubble removal |

Control System | PLC touchscreen for real-time monitoring and adjustments |

Adjustable Parameters | Speed and temperature control |

Material | 304/316L stainless steel, corrosion-resistant |

Cleaning | CIP/SIP cleaning system |

Compliance | Meets GMP standards |

Guangzhou Guanyu supports you with a 2-year warranty, lifetime maintenance, and a global service network. You can customize your mixer to fit your needs, making it a smart choice for any production line.

Vacuum Emulsifying Process

Material Loading

You start the vacuum emulsifying process by loading your raw materials into the mixing vessel. This vessel is usually made of stainless steel, which keeps your ingredients safe and clean. You can add liquids, powders, or even thick pastes. Many mixers, like the ones from Guangzhou Guanyu, have wide openings and hydraulic lifting covers. These features make it easy for you to load materials quickly and safely. You can also use automated feeders to add ingredients in the right order. This step is important because it helps you avoid clumping and ensures every batch starts with the correct mix.

Tip: Always check your ingredient list and loading sequence before starting. This helps you get the best results and reduces waste.

Vacuum Creation

After you load your materials, you create a vacuum inside the vessel. You use a vacuum pump to remove air and lower the pressure. This step is critical in vacuum emulsifying because it stops air bubbles from forming in your product. You select the right vacuum pump by looking at base pressure, pumping speed, and how clean the system needs to be. Oil-free pumps work well when you want to keep your product pure. You also use vacuum gauges to measure and control the pressure. Some gauges read the actual gas force, while others infer pressure from other signals. You need to choose the right gauge for your pressure range.

Vacuum chambers are designed to keep the pressure stable. Most processes work between 1 and 10 mbar, but some go much lower. Stable vacuum conditions help you avoid material degradation and keep your process consistent. When you compare vacuum creation to other mixing methods, you see that vacuum systems give you better control over laminate pressure, thickness, and mechanical strength. For example, using double vacuum bag chambers or pulsed infusion methods can increase mechanical properties like flexural strength by up to 24%. You also get fewer voids and more uniform products.

Mixing & Homogenizing

Once you reach the right vacuum level, you start mixing and homogenizing. You use high-shear mixers or homogenizers to break down particles and blend liquids that do not mix easily. The rotor-stator system spins at high speeds, creating strong shear forces. This action reduces droplet size and spreads ingredients evenly. Research shows that using a homogenizer at 8000 rpm for 2 minutes can produce emulsions with droplet sizes between 4 and 15 micrometers. If you use high-pressure homogenization, you can get even smaller droplets, down to 200 nanometers, which makes your emulsion more stable for up to 60 days.

You can use dynamic mixers for fast, powerful blending.

Static mixers offer simple design and reliable performance.

The type and amount of emulsifier you add also affect droplet size and stability.

Advanced tools like computer vision and AI help you monitor and control the process in real time.

Emulsification

During emulsification, you combine all your ingredients into a smooth, stable mixture. The vacuum environment helps you avoid air bubbles and keeps the texture even. The high-shear forces from the homogenizer break the droplets into tiny sizes. Studies show a strong link between smaller droplet size and better emulsion stability. For example, a regression model with an R² value of 0.9857 proves that smaller droplets lead to higher stability. Theories like DLVO and Stokes-Richardson-Zaki explain that small droplets resist merging and rise more slowly, so your product stays mixed longer.

You can also control factors like temperature, moisture, and additives to improve your emulsion. Higher curing temperatures can triple the strength of your product in the first week. Adding polymers or other agents can boost mechanical properties and durability. You use these adjustments to match your product’s needs, whether you make creams, sauces, or medicines.

Discharge

When your emulsion is ready, you move to the discharge stage. You open the discharge valve and let the finished product flow out of the vessel. You need to control the flow rate and pressure carefully. This helps you avoid waste and keeps your process efficient. Adding drag-reducing polymers to the flow line can improve suction and reduce resistance, making the discharge smoother. The design of the nozzle and diffuser also matters. Rounded throat designs and the right entry angle can minimize losses and boost efficiency.

You should monitor flow rates and pressures at the discharge line.

Adjusting valve controls can improve ejector efficiency.

The distance between the diffuser throat and nozzle exit affects vacuum and flow performance.

Finding the optimal flow rate gives you the best efficiency.

These steps in the vacuum emulsifying process work together to give you a high-quality, stable product every time. You get better control, less waste, and improved product performance.

Benefits

Product Stability

You want your products to stay fresh and effective for as long as possible. The vacuum mixing process helps you achieve this by creating stable emulsions and blends. Scientists have tested these methods and found several reasons why your products last longer:

FTIR spectroscopy shows no unwanted chemical reactions between ingredients, so your formula stays safe.

DSC analysis finds that the process changes crystals into a more stable form, which helps prevent spoilage.

Vacuum foam drying creates a porous solid with less moisture than other methods, making it easier to mix again and more stable.

Stability tests over three months show that products made with this process keep their size and quality, while others may separate or lose effectiveness.

The process also helps control how fast a drug releases, which can improve how well it works.

You avoid problems like hard, compacted cakes that make mixing harder in other drying methods.

Note: These results prove that using a vacuum system can make your creams, medicines, or foods more reliable and longer-lasting.

Air Removal

Air bubbles can ruin the texture and look of your product. When you use a vacuum system, you pull out trapped air before and during mixing. This step gives you a smooth, even blend every time. You also reduce the risk of oxidation, which can cause color changes or spoilage. Removing air helps you avoid foam and keeps your product looking and feeling its best.

You get a better texture.

You prevent unwanted chemical changes.

You improve shelf life.

Versatility

You need equipment that can handle many types of products. Vacuum mixers give you this flexibility. Case studies show that these machines work well with liquids, powders, pastes, and gels. You can use them in cosmetics, pharmaceuticals, food, and even nanomaterial production. Compared to older methods, vacuum mixers help you save time and get more even results. You can program settings, monitor the process in real time, and scale up from small batches to large production runs. This means you can make many different products with one machine.

You get consistent results from small to large batches.

You can control and adjust the process for each product.

Common Concerns

Cleaning

You need to keep your vacuum emulsifying mixer clean to avoid contamination and protect your products. Cleaning the machine after each use helps you prevent cross-contamination and maintain hygiene. Follow these steps to make sure your mixer stays in top condition:

Clean the mixer thoroughly after every batch.

Use only cleaning agents approved by the manufacturer.

After stopping the machine, focus on cleaning the working cavity, stator, and rotor.

Regularly check and clean the import and export filters to keep production running smoothly.

Keep metal scraps and hard materials out of the working chamber to avoid damage.

Maintain the rotor and emulsifying seal by keeping them clean.

If possible, install a cleaning cycle device near the mixer to make cleaning easier.

Tip: Following these steps helps you keep your equipment safe and your products high quality.

Maintenance

You want your mixer to last and work well for every batch. Regular maintenance keeps your machine running smoothly and reduces downtime. Check moving parts for wear and tear. Lubricate bearings and seals as recommended. Inspect the vacuum system for leaks or blockages. Replace worn gaskets and seals to prevent air leaks. Keep the control panel and sensors free from dust and moisture. Schedule routine inspections to catch small problems before they grow. When you follow a maintenance plan, you save time and money in the long run.

Customization

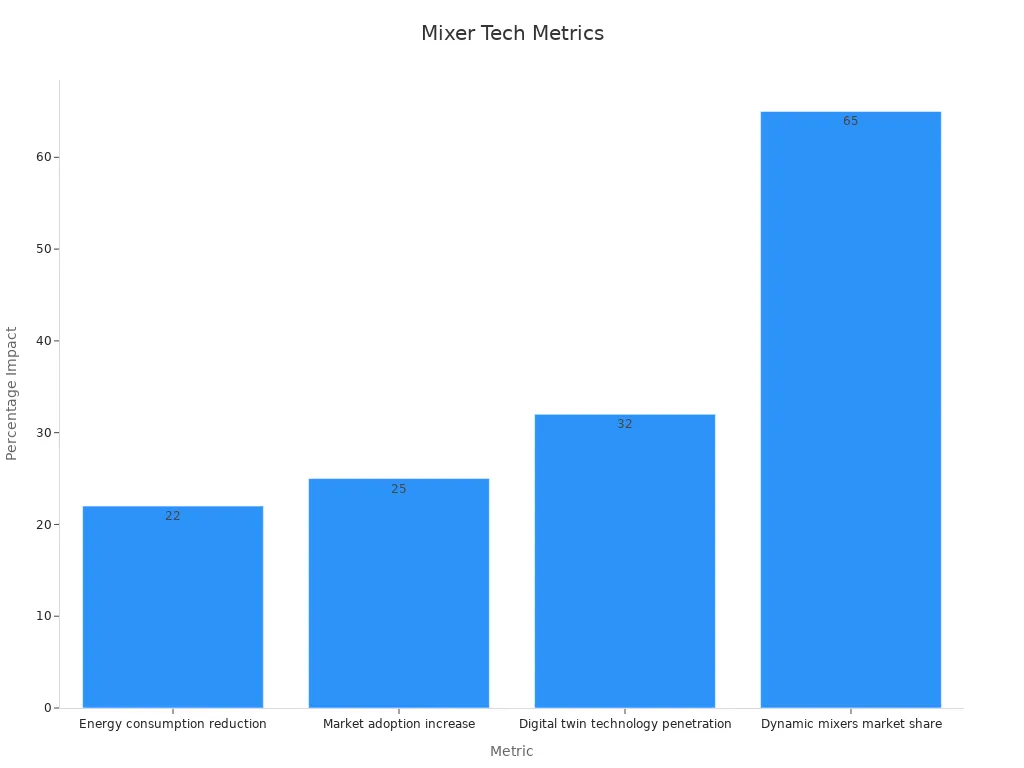

You may need a mixer that fits your unique production needs. Customization gives you many benefits. You can get precise temperature control, GMP compliance, and modular designs that save costs. Some mixers use AI-driven features to boost performance. For example:

Biotech companies use dual-shaft mixers with automated cleaning to prevent contamination.

Korean cosmetics makers have cut batch changeover time by 40% with integrated cleaning systems.

German chemical producers use corrosion-resistant chambers to reduce stabilizer use.

Battery manufacturers in China improve slurry production time by 33% with AI-powered sensors.

You can choose custom blade shapes, programmable vacuum levels, and energy-saving features. Modular designs let you add or remove features as your business grows. Customization helps you improve yield, product stability, and efficiency. Many industries, from cosmetics to food, rely on tailored mixers to meet strict standards and boost innovation.

You gain many advantages when you use advanced mixing equipment. Modern systems help you monitor batches in real time, save energy, and keep your products safe.

Multi-functional designs save space and speed up production.

Custom agitators and sensors let you meet unique needs.

After-sales support and quality checks help you meet industry standards and keep your plant running smoothly.

Consider these features when you look for the best solution for your business.

FAQ

What products can you make with a vacuum emulsifying mixer?

You can make creams, lotions, ointments, sauces, gels, and even some medicines. This mixer works well for cosmetics, food, and pharmaceutical products. You get smooth, stable results every time.

How does the vacuum help your mixing process?

The vacuum removes air from your mixture. You avoid bubbles and foam. Your product looks better and lasts longer. You also reduce the risk of oxidation, which can spoil your ingredients.

Can you clean the mixer easily?

Yes, you can clean the mixer quickly. Many machines have cleaning-in-place (CIP) systems. You follow simple steps to wash all parts. This keeps your products safe and your equipment in good condition.

Is it possible to customize your mixer for special needs?

You can customize your mixer for different batch sizes, recipes, or features. Choose special blades, control panels, or cleaning systems. Customization helps you meet your production goals.

What support do you get after buying a mixer?

You receive a 2-year warranty, lifetime maintenance, and global service support. Engineers help with installation, training, and troubleshooting. You always have help when you need it.