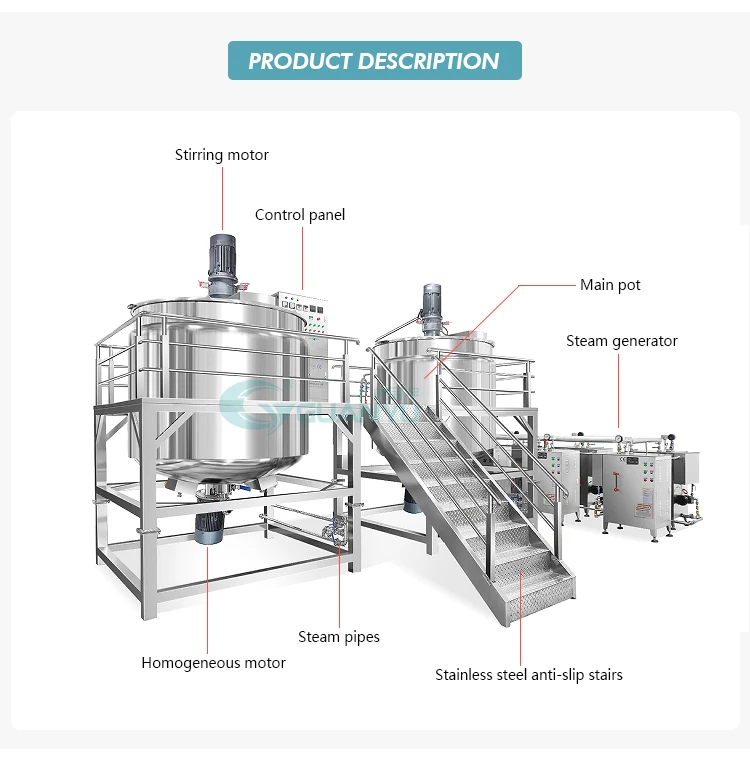

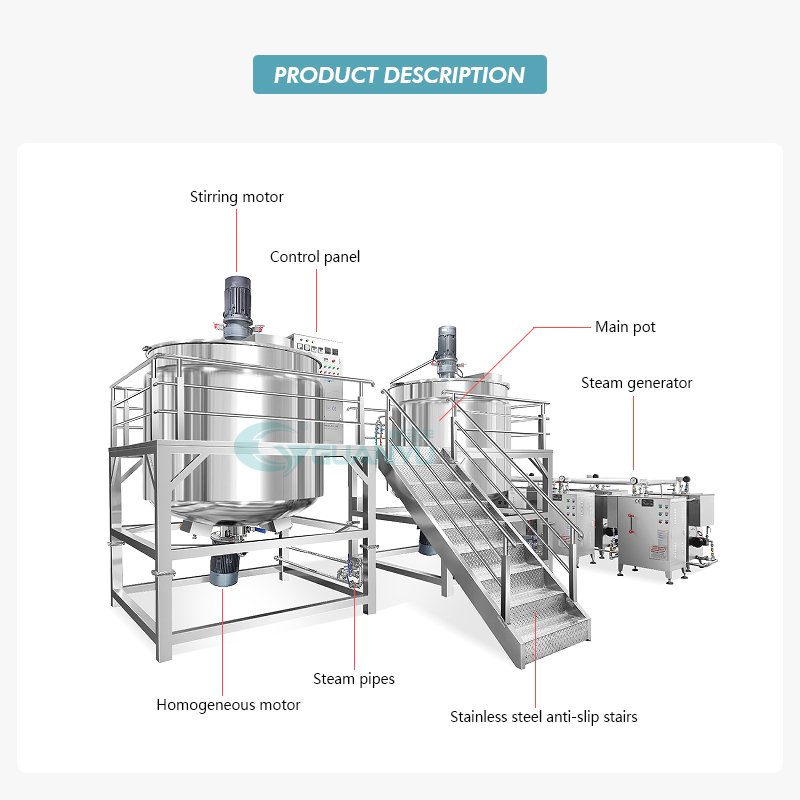

3000l Open Steam Heated Combination Stirring Pot Shampoo Mixer Blender Liquid Soap Making Machinery For Dish Washing

Products Description

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products ofdifferent processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.

◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

Model | Volume(L) | Blending power(kw) | Blending rotation speed(r/min) | Homogenizing power(kw) | Homogenizing rotation speed(r/min) | Heating method |

GYM-200 | 200 | 1.5 | 0~63 | 4.0 | 0~3200 | Steam heating Or Electric heating |

GYM-500 | 500 | 3.0 | 0~63 | 7.5 | 0~3200 | |

GYM-1000 | 1000 | 4.0 | 0~63 | 11 | 0~3200 | |

GYM-1500 | 1500 | 5.5 | 0~63 | 11-15 | 0~3200 | |

GYM-2000 | 2000 | 7.5 | 0~63 | 15-18.5 | 0~3200 | |

GYM-3000 | 3000 | 7.5-11 | 0~63 | 18.5-22 | 0~3200 | |

GYM-5000 | 5000 | 11-15 | 0~63 | 18.5-22 | 0~3200 |

Mixing paddle

Variable frequency speed regulation is 0-62r/min, so that different materials can be mixed evenly. The shape of the mixing paddle will be designed according to your materials

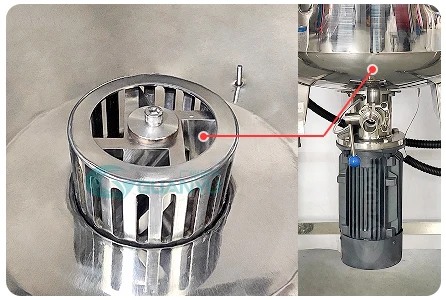

Homogenizer

Frequency conversion speed regulation 0-3200r/min, homogeneous shearing head high-speed shearing materials, so that the materials are completely broken and mixed!

Heating device

Electric heating or steam heating can be selected, and the material is heated through the interlayer to achieve the ideal

stirring and emulsification state.

stirring and emulsification state.

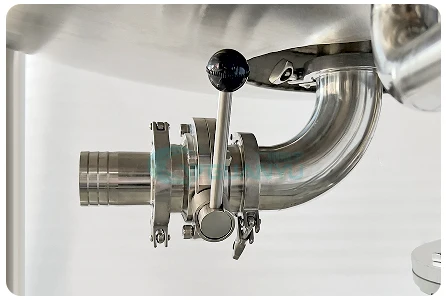

Discharge

The round bottom of the pot is designed to make the bottom discharge cleaner and reduce the residue of materials (if necessary, a discharge pump can be equipped to directly extract materials)

Console

The control box includes settings such as homogeneous shearing, frequency conversion speed regulation mixing,

working timing, vacuum extraction, interlayer heating, etc.

working timing, vacuum extraction, interlayer heating, etc.

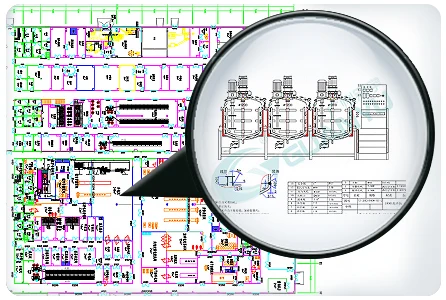

Service

Use internationally renowned brand components to ensure the quality of the equipment and longer service life

Kristofer –

Hey There. I discovered your weblog the use of msn.

That is a very well written article. I will make sure to bookmark it and return to read more of your helpful info.

Thanks for the post. I’ll certainly comeback.!

Fermin –

Howdy! Do you know if they make any plugins to help with SEO?

I’m trying to get my site to rank for some targeted keywords but I’m not seeing very

good gains. If you know of any please share. Many thanks!

You can read similar blog here: Wool product